Dismounting tool for hot-rolling shear blade knife rest clamping cylinder

A technology for disassembling tooling and clamping cylinders, applied in the field of rolling machinery, can solve the problems of low disassembly efficiency, long time consumption, and difficulty in disassembling clamping cylinders, saving maintenance and replacement time, improving efficiency, and reducing the cost of disassembling clamping cylinders. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

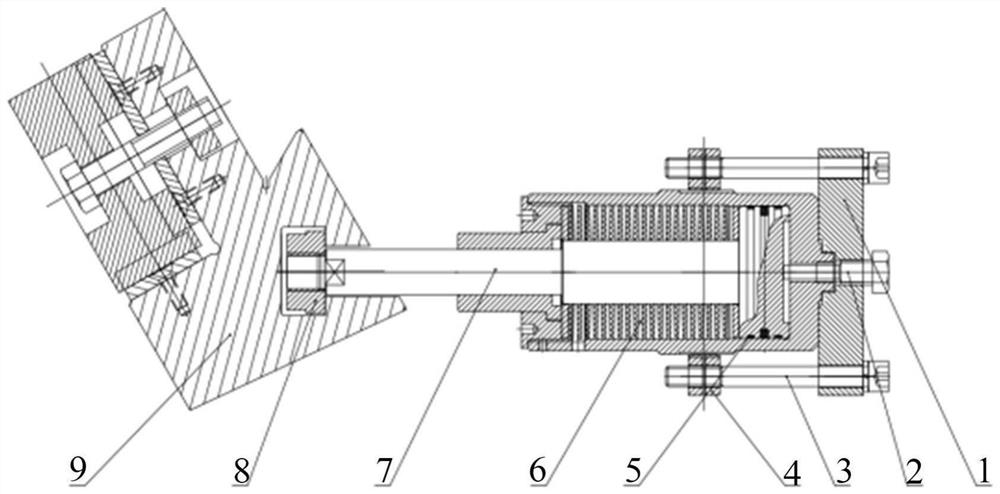

[0016] In the present invention, the clamping cylinder device of the hot-rolled shearing blade holder is disassembled, and the assembly structure is as follows: figure 1 As shown in the figure, it includes a tooling chuck 1, and a stop is formed on the bottom surface of the tooling chuck 1, and the stop is sleeved with the top wire 2.

[0017] The stop is that the tooling chuck 1 has a stepped groove to the inside around the axis. The stepped groove is clamped to the rear boss of the clamping cylinder block 4. A center hole is opened in the groove, and the center hole is sleeved to the top. Wire 2, the top wire 2 runs through the tooling chuck 1, the top wire 2 is cylindrical, the end face of the top wire 2 is set to a spherical surface, the surface of the top wire 2 is provided with an external thread, and the other end face of the top wire 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com