PET sheet hobbing production and excess material recovery device

A recovery device and rolling cutting technology, applied in grain processing, metal processing, etc., can solve the problems of high manufacturing cost, low production capacity, poor overall effect, etc., and achieve the effect of high recycling quality and thorough crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

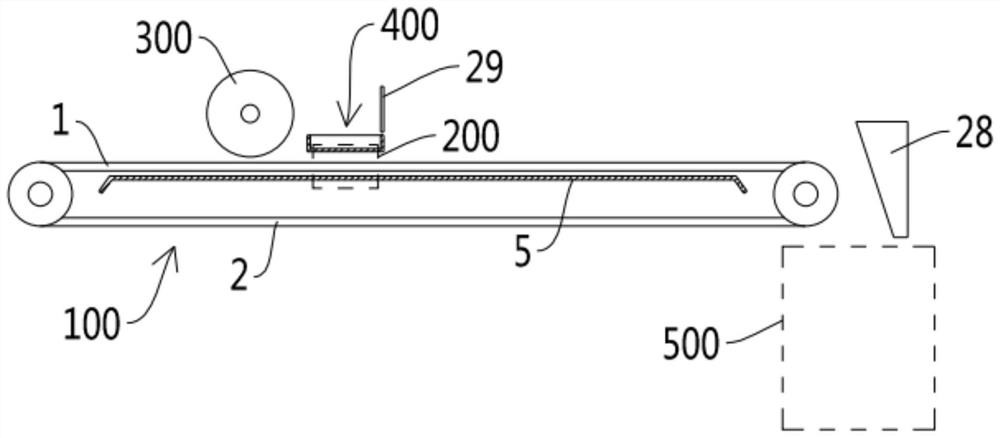

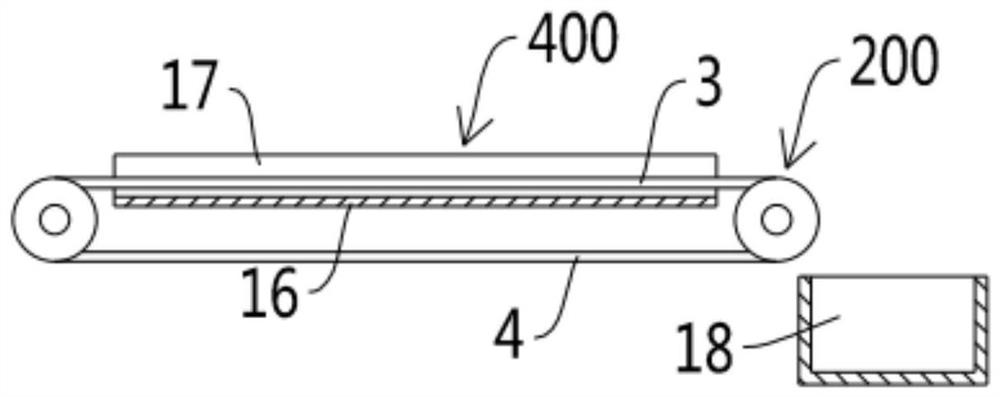

[0023] see Figures 1 to 3 As shown, a PET sheet roll-cutting production and residual material recovery device involved in this embodiment includes a first conveyor belt assembly 100 extending horizontally left and right, and a second conveyor belt assembly 200 extending horizontally front and rear. The conveyor belt assembly 100 has a first upper conveyor belt 1 and a first lower conveyor belt 2, the second conveyor belt assembly 200 has a second upper conveyor belt 3 and a second lower conveyor belt 4, and a pallet is provided below the first upper conveyor belt 1 5. There is a rolling and cutting roller assembly 300 above;

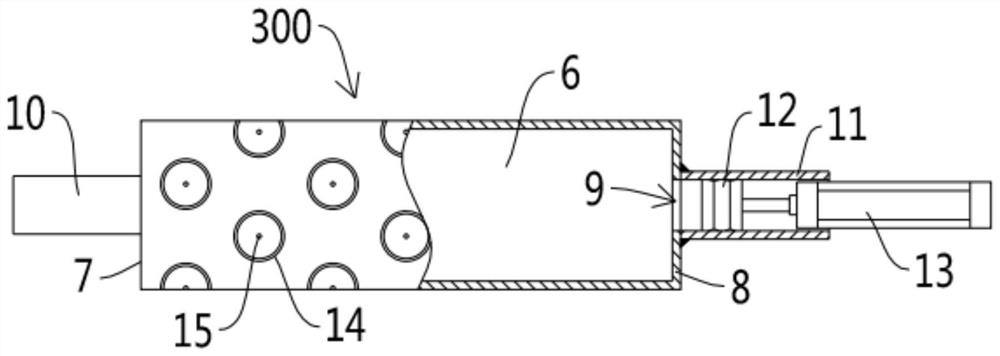

[0024] The rolling-cutting roller assembly 300 includes a rolling-cutting drum 6, one end of the rolling-cutting drum 6 is provided with a first sealing plate 7, the other end is provided with a second sealing plate 8, and the second sealing plate 8 is provided with a main air port 9. The sealing plate 7 is provided with a first transmission shaft 10, ...

Embodiment 2

[0030] see Figures 1 to 4 As shown in the figure, a PET sheet roll-cutting production and residual material recovery device involved in this embodiment, on the basis of Embodiment 1, is further configured such that the blanking end of the first conveyor belt assembly 100 is provided with The crushing and recycling device 500; the crushing and recycling device 500 includes a crushing box 19, the top of the crushing box 19 is provided with a feeding port 20, and the bottom is provided with a discharging port 21, and the crushing box 19 is provided with at least a A set of pulverizing rollers 22, below the pulverizing roller 22 is provided with a slope plate 23 arranged in an inclined manner, the slope plate 23 is provided with a filter plate 24 arranged below the pulverizing roller 22, the lower end of the slope plate 23 is close to the crushing Rolling rollers 25 are provided between the inner wall of the box 19, the lower end of the slope plate 23 and the inner wall of the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com