Spent fuel storage pool system and installation/replacement method of filter element of spent fuel storage pool system

A technology for spent fuel and water pools, applied in the field of nuclear engineering, can solve problems such as insufficient processing capacity, achieve the effects of remote installation, maintenance and replacement, reduce radiation risks, and facilitate hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment discloses a spent fuel storage pool system, which includes a spent fuel storage pool and a purification unit. The purification unit is set in the spent fuel storage pool. The purification unit includes a pump and a purification section, and the pump is communicated with the input end of the purification section. , the pump is used to transport the pool water in the spent fuel storage pool to the purification section, the purification section is used to purify the pool water transported by the pump, and the output end of the purification section is connected to the spent fuel storage pool to discharge the purified pool water back to into the spent fuel storage pool.

[0038] Compared with the prior art, the spent fuel storage pool system of this embodiment can realize purification in the pool, solve the problem of insufficient processing capacity in the purification outside the pool, and meet the operation requirements of large spent fuel storage pools.

...

Embodiment 2

[0063] This embodiment discloses a method for installing / replacing a filter element, which is used in the spent fuel storage pool system described in Embodiment 1, which includes an installation step and a replacement step.

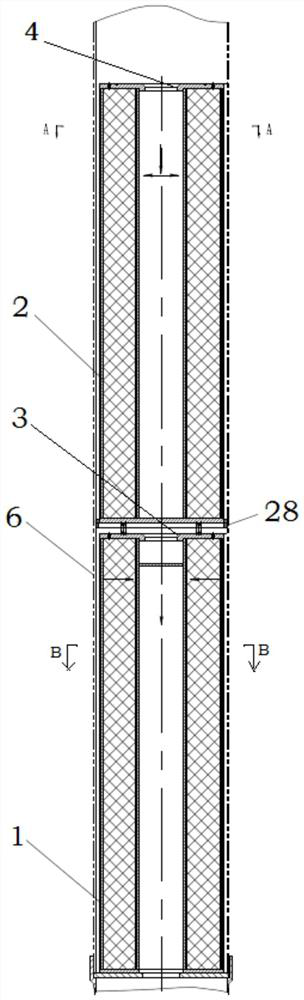

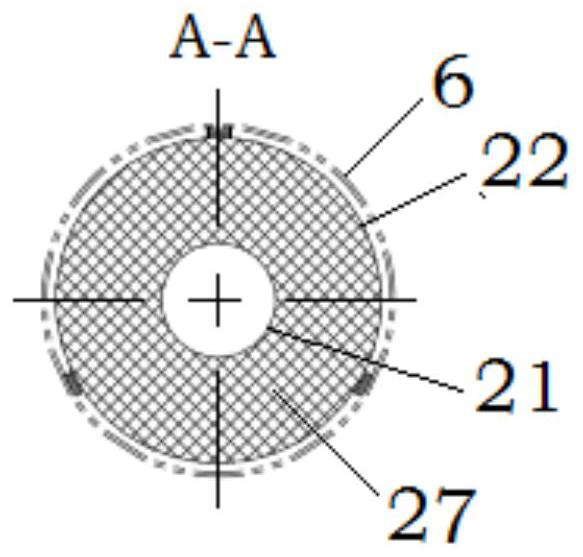

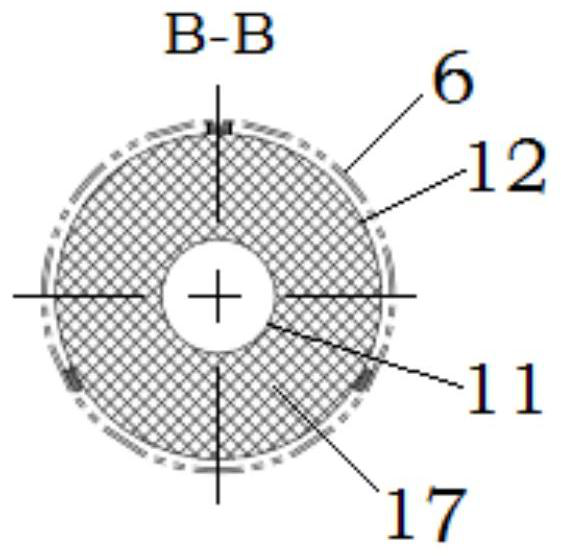

[0064]The installation steps include: connecting the spreader to the first spreader interface 3 , hoisting the first hanging basket 1 to the segment body of the spent fuel storage pool system through the spreader, and installing the first hanging basket 1 on the bottom of the segment body 6 Then connect the sling to the second sling interface 4, and lift the second sling 2 to the segment body 6 of the spent fuel storage pool system through the sling, so that the bottom of the second sling 2 The end is installed on the top of the first gondola;

[0065] The replacement steps include: firstly connect the spreader to the second spreader interface 4, hoist the second hanging basket 2 from the spent fuel storage pool through the spreader to a non-radioactive o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com