Digital twin modeling method for rolling mill roller lathe in bar steel rolling workshop

A technology of a roll lathe and a modeling method, which is applied in simulators, computer control, program control, etc., can solve problems such as reporting on the modeling method of digital models of machine tools, achieve rich data scalability, accurate real-time mapping, and is conducive to reused effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

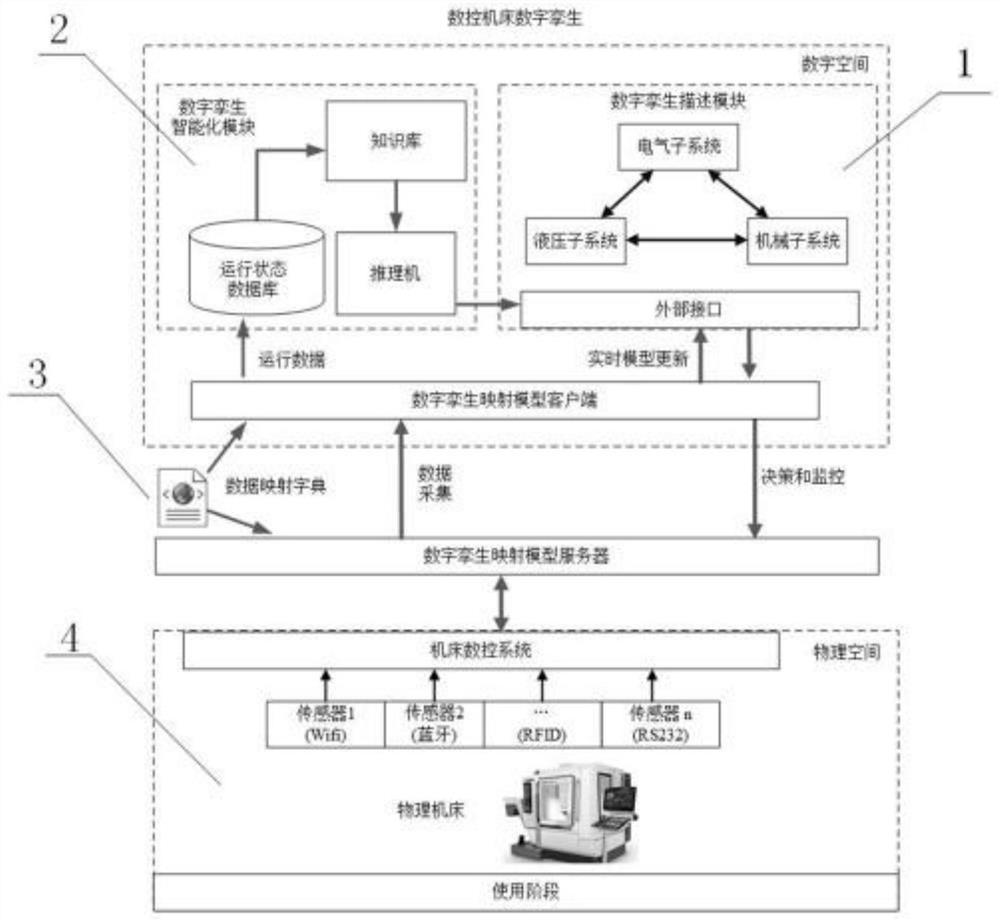

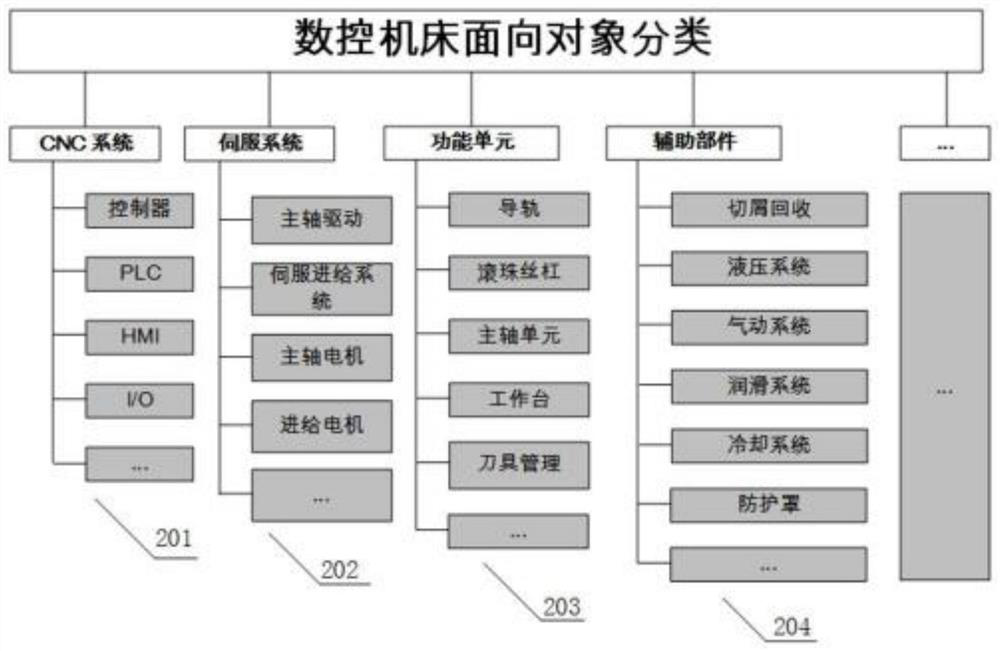

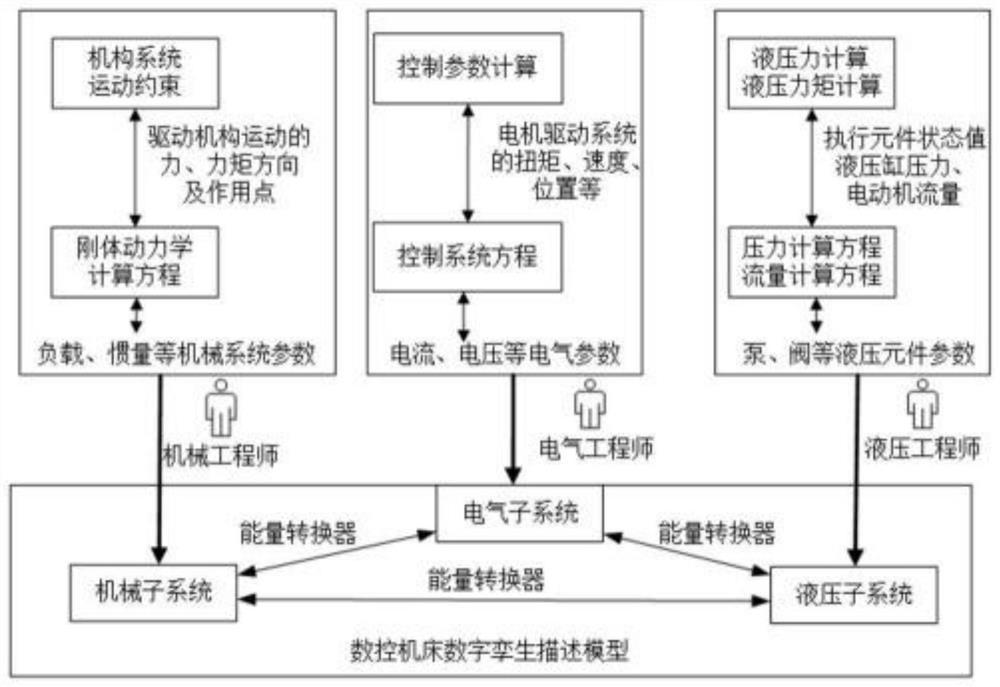

[0022] like Figure 1 to Figure 5 As shown, the present embodiment provides a digital twin modeling method for a rolling mill roll lathe in a bar rolling workshop, including a physical space 4, a digital twin digital space, and a digital twin mapping model 3, and the digital twin digital space is connected by the digital twin mapping model 3 and The physical space 4 is connected; wherein, the physical space 4 includes a numerical control machine tool, a data sensor and a numerical control system, the data sensor is installed on the numerical control machine tool, the data sensor is connected with the numerical control system through different data interfaces, and the numerical control system maps the model through the digital twin 3. Collect relevant data and analyze the protocol; the digital twin digital space includes a digital twin description model 1, a digital twin intelligent model 2, and the digital twin intelligent model 2 realizes the intelligence of the digital twin o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com