Heat dissipation method of electronic integrated module

A technology of integrated modules and heat dissipation methods, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of unfavorable deep integration and miniaturization of intelligent equipment, poor heat dissipation performance of electronic integrated modules, etc., to improve heat dissipation efficiency and heat dissipation effect. , Improve the heat dissipation effect, reduce the volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

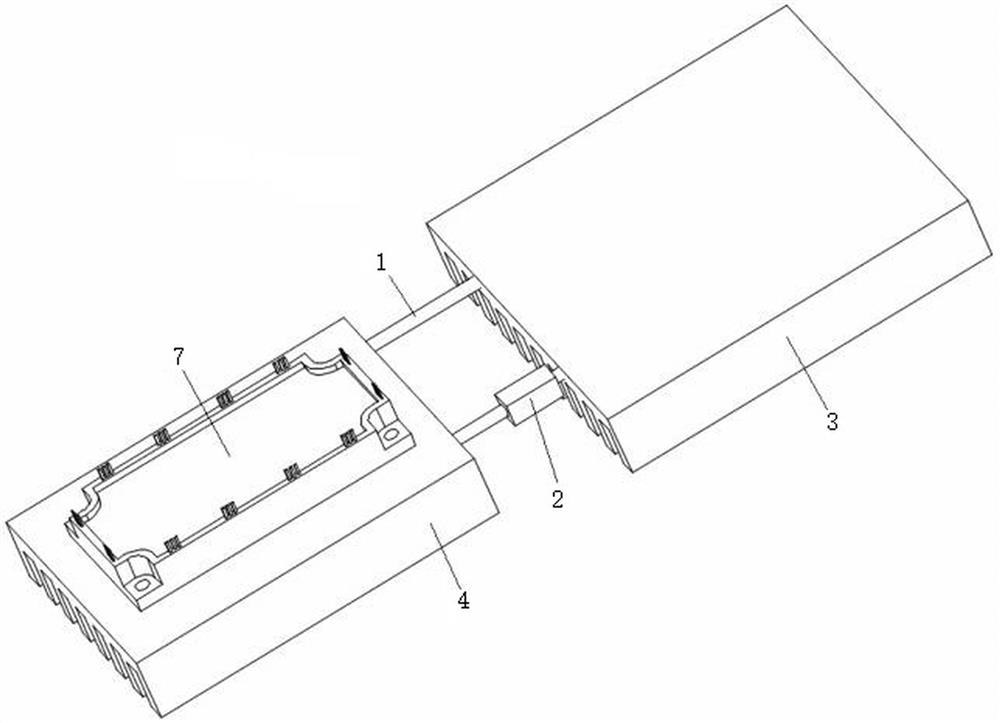

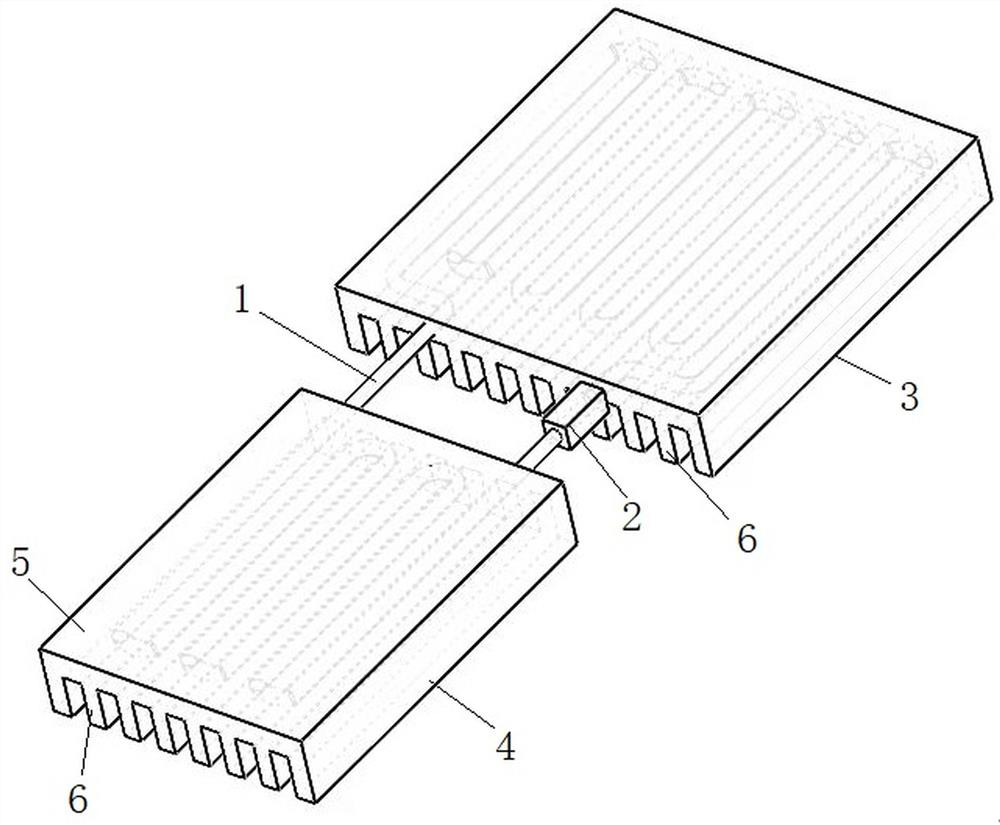

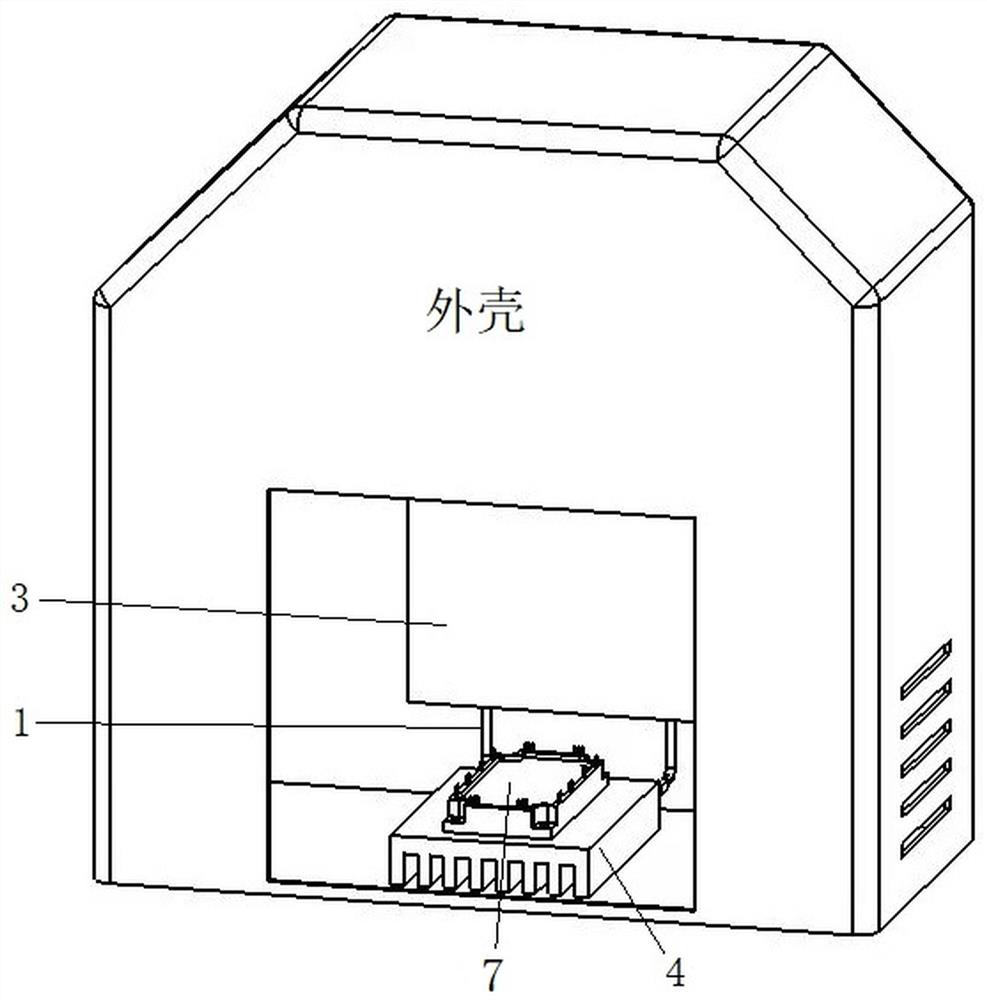

[0036] This embodiment discloses a heat dissipation method for an electronic integrated module. The method mainly uses a combination of lateral conduction heat dissipation and vertical conduction heat dissipation to dissipate heat to the electronic integrated module 7, which can reduce the volume of the vertical heat dissipation structure under the premise of reducing heat dissipation. Effectively improve heat dissipation efficiency and heat dissipation effect. It should be noted that the lateral heat dissipation refers to using a circulating cooling medium to laterally exchange part of the heat to another heat dissipation area for heat dissipation, so as to achieve the purpose of increasing the heat exchange rate and the heat transfer efficiency.

[0037] Specifically, the heat dissipation method includes the following steps:

[0038] Step A: First set the vertical radiator 4 and the lateral auxiliary radiator 3, and preferably the volume of the lateral auxiliary radiator 3 i...

Embodiment 2

[0046] This embodiment verifies the method described in Embodiment 1, as follows:

[0047] In this embodiment, a 50A IPM product is used as an example, and the temperature of the electronic integrated module 7 is actually measured to be 120° C. when the ordinary radiator is energized at 50A according to the background art. 96°C, the temperature has decreased by 24°C, a decrease of about 20%.

[0048] Compared with the temperature reduction of 18° C. in the patent documents cited in the background art, the temperature reduction of the present invention is larger. Furthermore, because the present invention also enables the volume of the vertical radiator 4 to be reduced to match the volume of the electronic integrated module 7, the volume of the intelligent equipment can also be effectively reduced, and the effect of the present invention is also better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com