Volume-variable sodium hypochlorite generator

A sodium hypochlorite generator technology, applied in cells, electrolysis components, electrolysis process, etc., can solve the problems of unable to adjust the volume, fixed volume, low electrolysis efficiency, etc., to improve the electrolysis effect, good stability, and reduce electrolysis energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

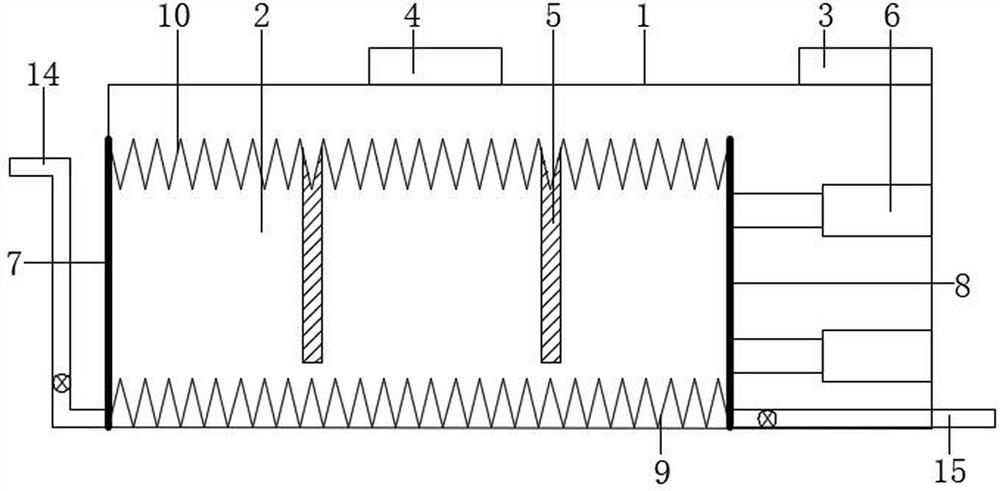

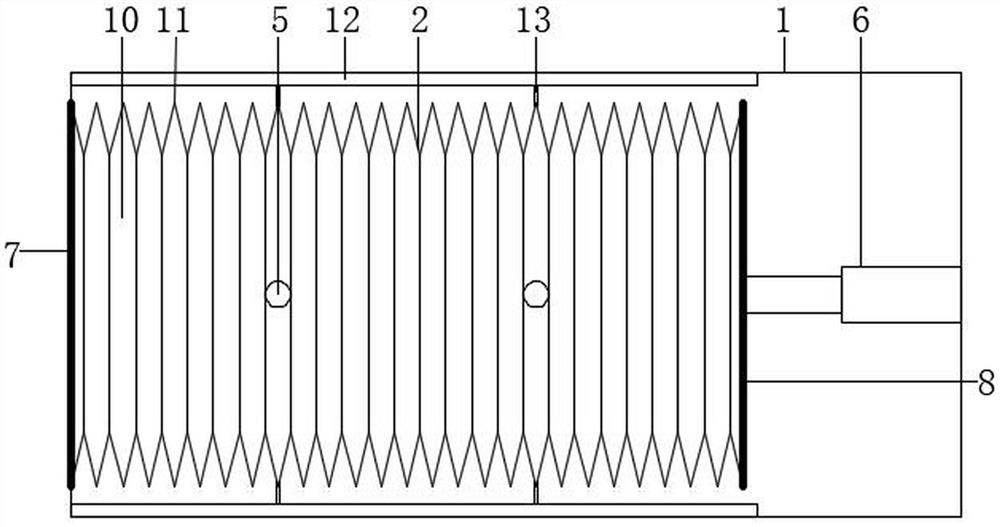

[0032] The present embodiment provides a volume-variable sodium hypochlorite generator, the structure of which is as follows figure 1 , 2 As shown, it includes an outer tank body 1, an electrolytic vessel 2, a controller 3, a power supply 4, an anode and an anode electrode 5 and a pushing mechanism 6, wherein,

[0033] The outer tank body 1 is preferably a square structure with an upper opening, and a horizontal plate is fixed at the upper opening. The controller 3 and the power supply 4 can be fixed above the outer tank body 1 through the horizontal plate.

[0034] The electrolytic container 2 is placed at the left end of the outer tank body 1. To prevent the electrolytic container 2 from shaking, the left end of the electrolytic container 2 and the inner wall of the left end of the outer tank body 1 can be fixed with bolts. The electrolytic vessel 2 is preferably a square structure, which includes a left end plate 7, a right end plate 8, a bottom plate 9, a top plate 10 and...

Embodiment 2

[0040] This embodiment provides a sodium hypochlorite generator with variable volume. On the basis of Embodiment 1, this embodiment further limits the pushing mechanism 6, such as figure 1 As shown, the pushing mechanism 6 includes two sets of hydraulic cylinders. In order to ensure a better compression effect, it is preferable that the two sets of hydraulic cylinders are respectively fixed in the upper middle and the lower middle of the right end plate 8. Under the joint action of the two sets of hydraulic cylinders, the control can be The telescopic body expands and contracts to achieve effective adjustment of the internal volume of the electrolytic vessel 2 .

Embodiment 3

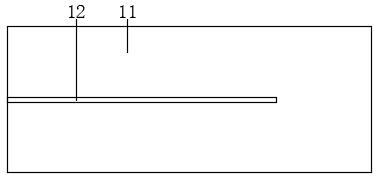

[0042] On the basis of Embodiment 1 or Embodiment 2, in this embodiment, a positioning structure is added in the outer tank body 1 to improve the stability of the electrolytic vessel 2 during expansion and contraction. like image 3 As shown, in this embodiment, guide grooves 12 are respectively provided in the middle of both sides of the outer tank body 1, and positioning columns 13 are respectively provided on the two side plates 11 of the retractable body, and one end of the positioning columns 13 is fixed on the side plates 11. The other end is located in the guide groove 12 . Of course, in order to ensure the positioning effect, a reinforcing block or a reinforcing rib may also be provided on the side plate 11 in the area where the positioning column 13 is set, so as to avoid the deformation of the side plate 11 . When the pressing mechanism 6 compresses the electrolytic container 2, the electrolytic container 2 will shrink along the length direction under the cooperatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com