Food processing device with positioning and placing functions

A food processing device and function technology, which is applied in the field of food processing devices with positioning and placing function, can solve the problems of green jujube sorting, green jujube damage, and excessive pulp removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

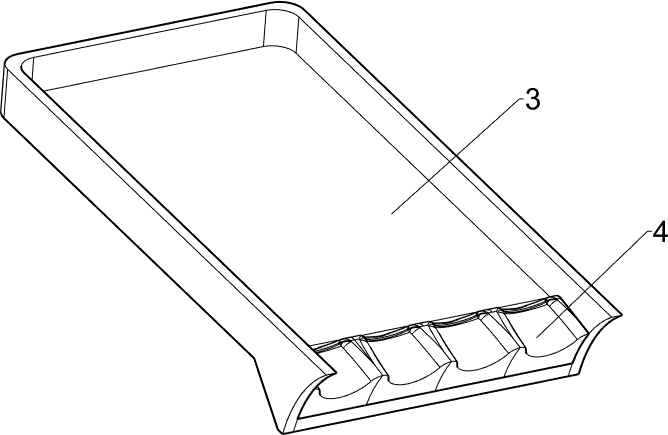

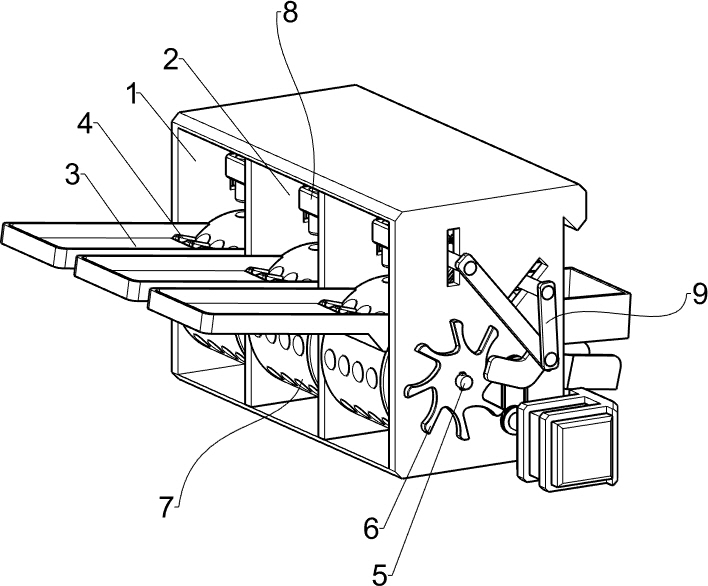

[0027] A food processing device with positioning and placing function, combined with Figure 1-Figure 7 As shown in the figure, an installation frame 1 is included. The interior of the installation frame 1 is equidistantly installed with two vertical plates 2 through bolts. A blanking frame 3 is also installed between the vertical plates 2. The height of the left part of the three blanking frames 3 is higher than the height of the right part. There are several inclined grooves on the frame 4. The left part of the inclined groove on the limit frame 4 gradually decreases to the right part, so that the green jujube slides vertically to the right, so as to avoid removing too much pulp or causing damage to the green jujube. Install the frame 1 A rotating shaft 5 is rotatably installed between the two vertical plates 2. The front part of the rotating shaft 5 is installed with an intermittent runner 6 through a key. Between the rack 1 and the upper left sides of the two vertical pla...

Embodiment 2

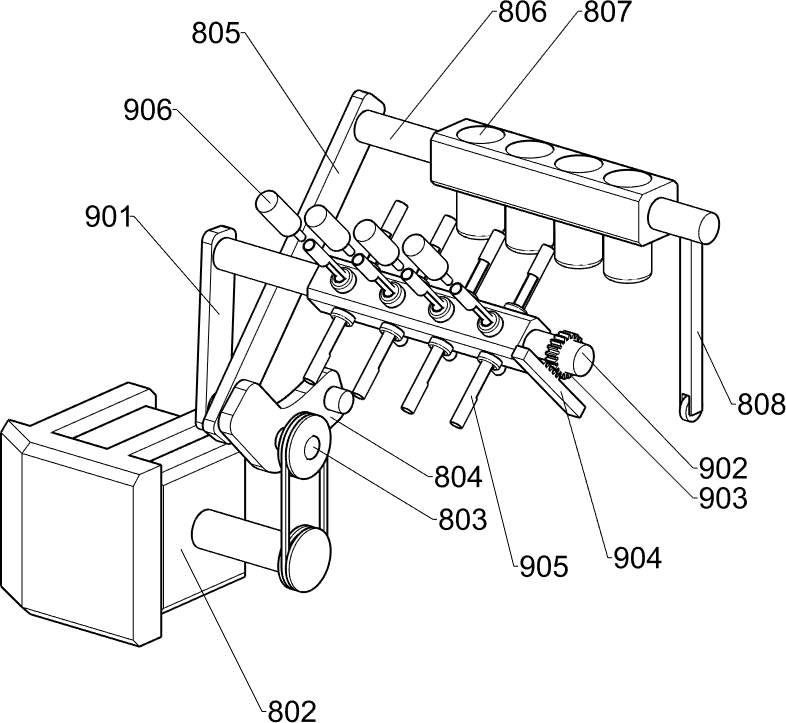

[0030] On the basis of Example 1, combined with Figure 4 and Figure 5 As shown, the clamping and limiting mechanism 7 includes a fixed plate 701, there are three fixed plates 701, the three fixed plates 701 are connected to the rotating shaft 5 at intervals, and the upper right side of the installation frame 1 and the two vertical plates 2 are fixed Three collecting frames 702 are installed, and the heights of the right parts of the three collecting frames 702 are all lower than the heights of the left parts; The material frame 703 is high on the left and low on the right, and drums 704 are installed on the rear sides of the three fixed disks 701. The three drums 704 are slidingly matched with the adjacent collecting frame 702 and the discharging frame 703 respectively. The walls are provided with several groups of holding cavities 705, the holding cavities 705 are used to hold green dates, a group of holding cavities 705 are provided with at least three, and the inner side...

Embodiment 3

[0038] On the basis of Example 2, combined with Figure 8As shown, it also includes a screening anti-blocking mechanism 10, the screening anti-blocking mechanism 10 includes a support frame 101, there are three support frames 101, and the upper part of the three support frames 101 is rotatably installed with a rotating ring 102, and the three rotating rings There is a screening cylinder 103 fixed between 102, the screen hole of the screening cylinder 103 gradually increases from front to back, the front part of the screening cylinder 103 is higher than the rear part, and the inclination angle of the screening cylinder 103 is 15°, which is used for the screening cylinder The green jujubes in 103 slide to the right for screening. During the rotation of the screening drum 103, the green jujubes in the screening drum 103 slide backward to screen the green jujubes, so that the green jujubes can be sorted into three levels. The outer sides of the two rotating rings 102 are fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com