Refractory material spraying device and method

A technology of spraying device and refractory material, which is applied in the direction of spraying device, etc., can solve the problems of reducing the efficiency of power utilization, reducing the stability of fire resistance, and insufficient efficiency of coordination, so as to improve environmental protection and energy saving performance, improve uniformity, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

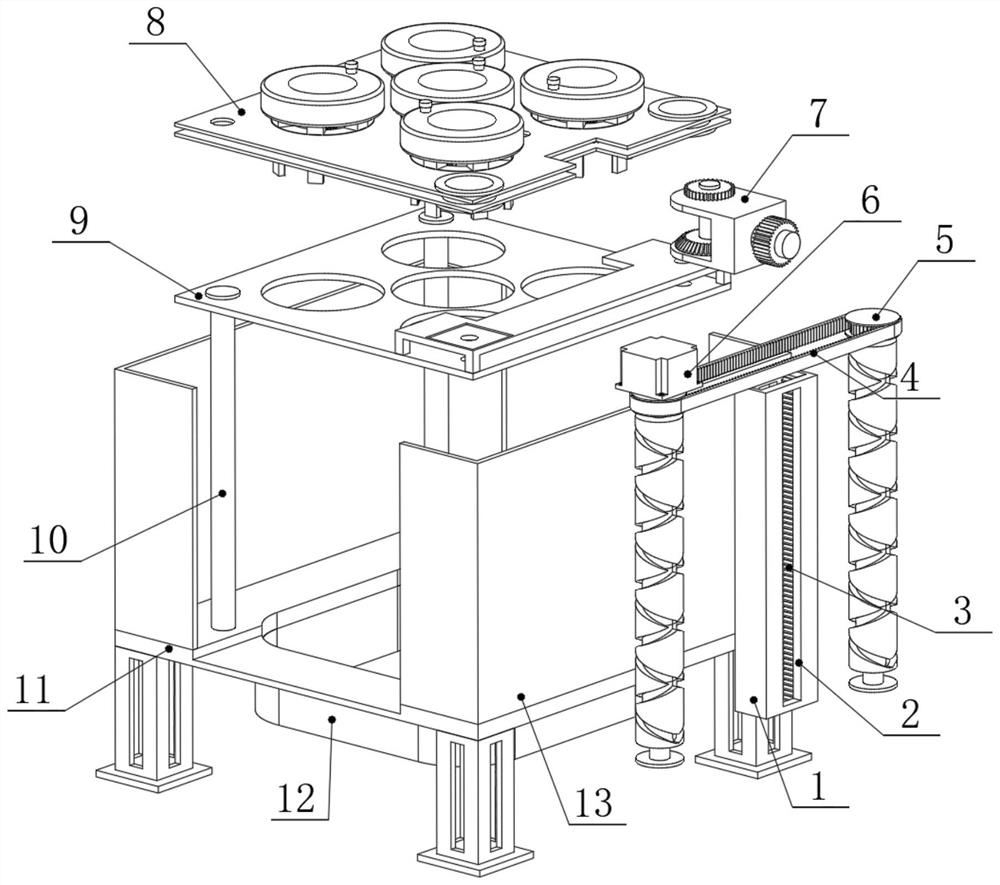

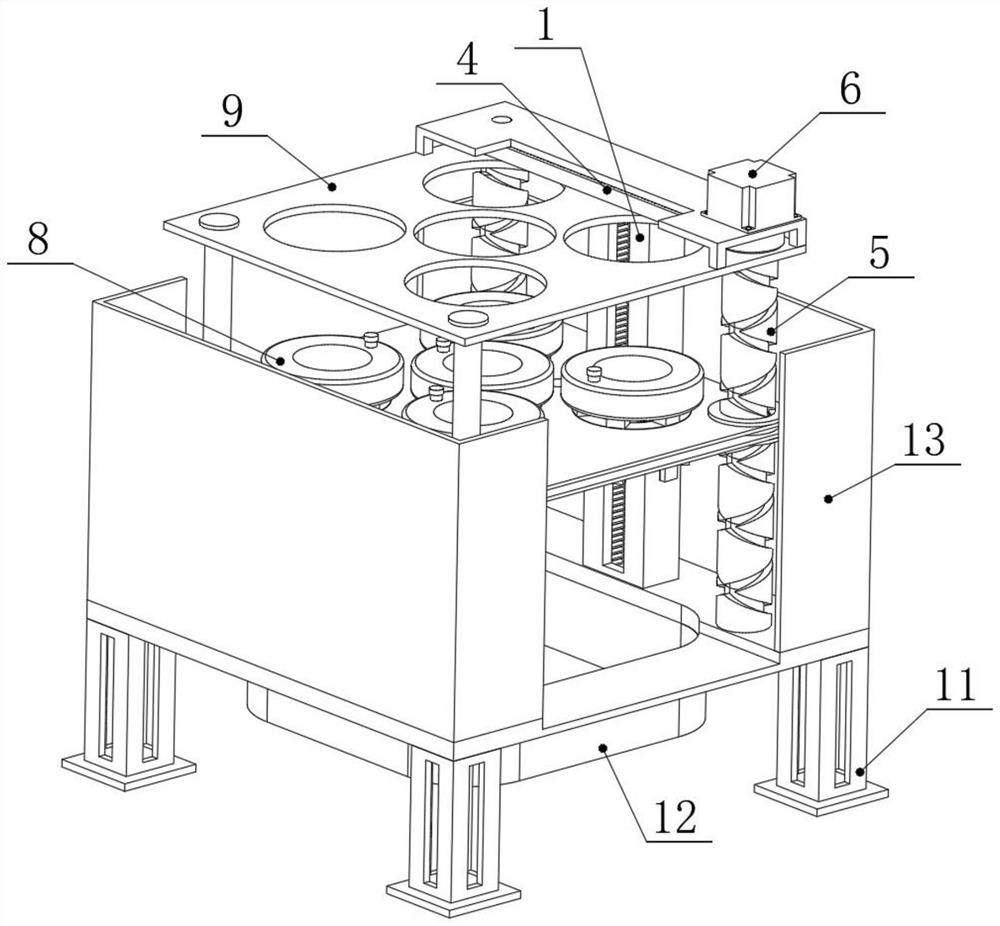

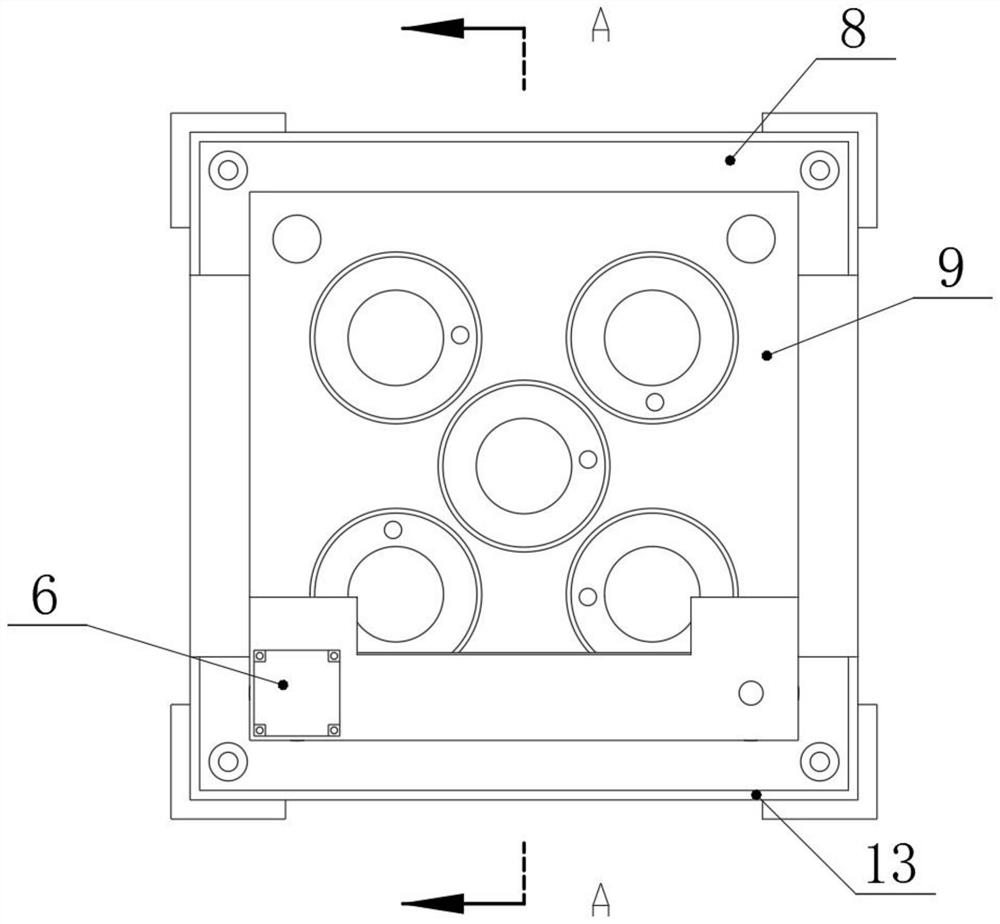

[0039] see Figure 1-12, the present invention provides a technical solution: a refractory material spraying device, including a connection card frame 11 for support, a guide sliding shaft 10 is symmetrically fixed on one side of the upper end face of the connection card frame 11, and is located in the connection card frame 11 The other side of the upper end face of the upper end face is symmetrically rotated and clamped with the guide device 5, and the top surfaces of the two sets of guide sliding shafts 10 and the two sets of guide devices 5 are fixedly installed with a support card plate 9, and the upper end face of the support card plate 9 is facing one of the groups. A servo motor 6 is fixed at the guide device 5, a guide slide 1 is fixed on the upper end surface of the connection card frame 11 near the middle of the two sets of guide devices 5, and a limit chute 2 is set on the inner end surface of the guide slide 1, and the connection card The upper end surface of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com