Method for controlling coaxiality between components

A control method and coaxiality technology, applied in manufacturing tools, metal processing equipment, metal processing, etc., can solve the problems of unsuitable high-precision equipment assembly, large error, low efficiency, etc., and achieve ingenious design, simple method, and improved The effect of running performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

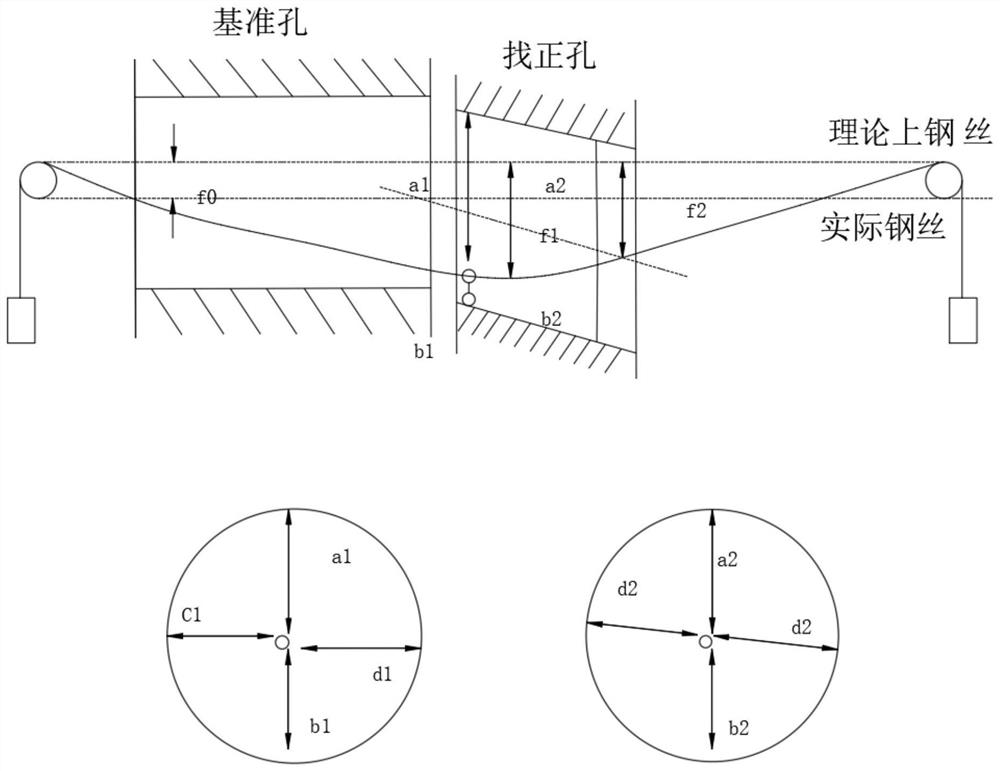

[0031] see Figures 1 to 2 , in an embodiment of the present invention, a method for controlling the coaxiality between components includes the following steps:

[0032] S1: Place the reference piece and the alignment piece on the same horizontal plane, use the steel wire to penetrate the reference hole and the alignment hole on the reference piece and the alignment piece, and the steel wire is parallel to the axis of the reference hole;

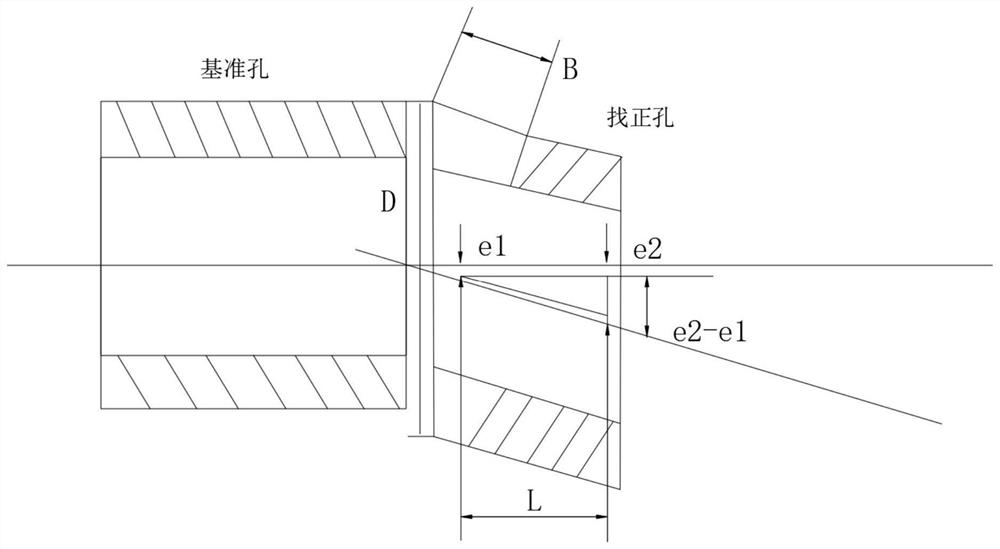

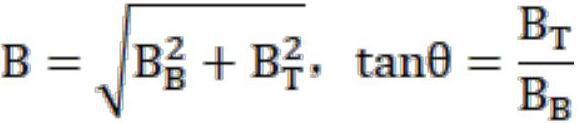

[0033] S2: Calculate the disturbance difference, and calculate the coaxiality error of the alignment hole through the disturbance difference;

[0034] S3: Calculate the machining amount of the end face of the alignment hole according to the coaxiality error of the alignment hole;

[0035] S4: Adjust the alignment hole according to the calculated machining amount of the end face of the alignment hole, so that the alignment hole and the reference hole fit together to form a component.

[0036] Further, the calculation formula of the disturba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com