Calibration tool for furniture production and processing

A technology for school tools and furniture, used in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of lack of auxiliary function correction function, inconvenient use, and single-function school tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

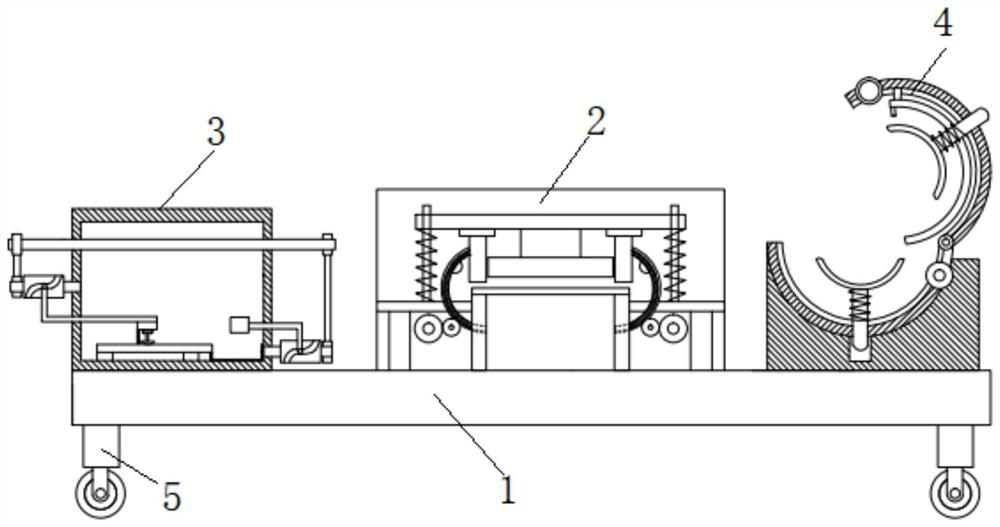

[0091] The embodiments of the present invention provide school tools for furniture production and processing, such as Figure 1-6 shown, including:

[0092] The base 1, the lower end of the base 1 is provided with a mobile device 5;

[0093] The straightening device is arranged on the upper end of the base 1, and the straightening device includes: a flat plate straightening device 2;

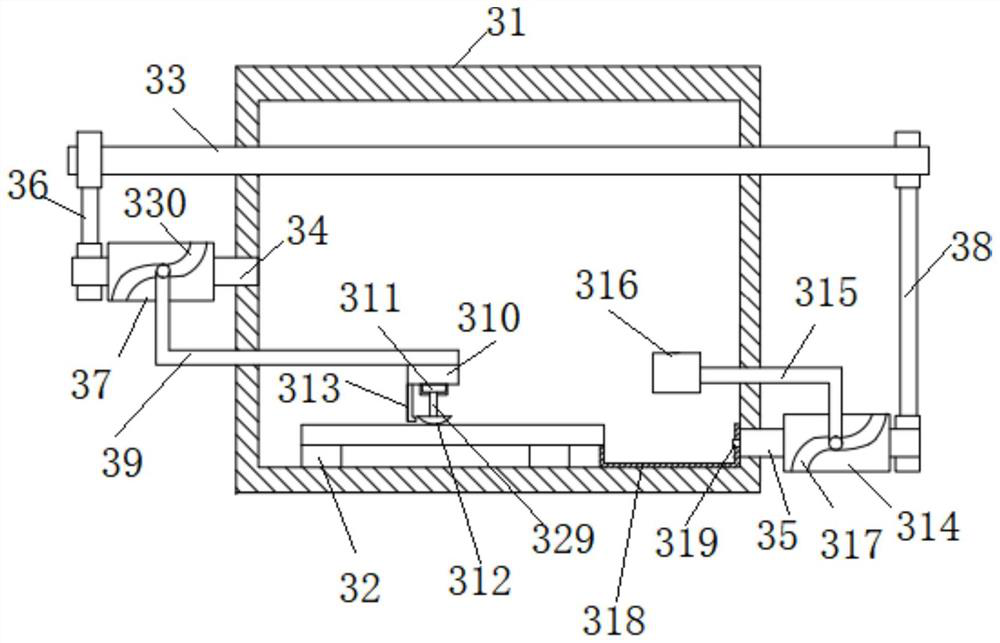

[0094] The grinding device 3 is arranged on the upper end of the base 1 .

[0095] The moving device can be an existing moving wheel, or an existing moving wheel with a self-locking function; When the base is installed, increase the contact area with the ground or other surfaces;

[0096] The working principle and beneficial effects of the above technical solutions are as follows: by setting the moving device 5, it is convenient to move the base 1; Grind the plate before straightening to avoid the poor surface quality of the plate affecting the straightening effect. The above-mentioned scho...

Embodiment 2

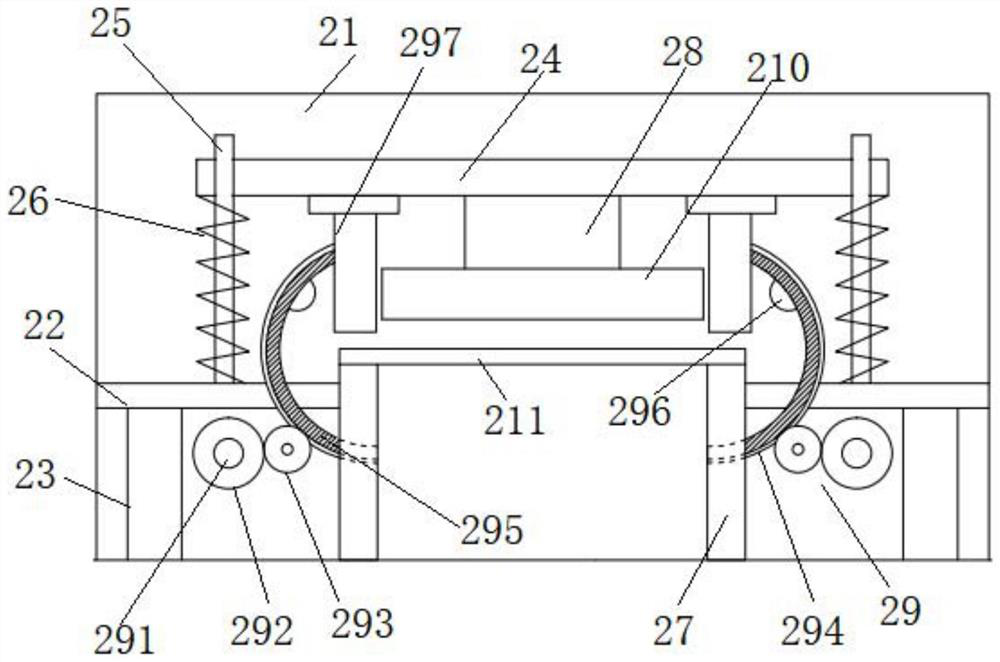

[0098] On the basis of Example 1, as figure 2 As shown, the flat plate straightening device 2 includes: a straightening box 21, which is fixedly connected to the upper end of the base 1, and the straightening box 21 is provided with:

[0099] The first horizontal installation plate 22, the lower end of the first horizontal installation plate 22 is fixedly connected with a number of first vertical support rods 23, and the first vertical support rods 23 are fixedly connected with the lower end of the inner wall of the straightening box 21 ;

[0100] The second horizontal mounting plate 24 is disposed directly above the first horizontal mounting plate 22;

[0101] A plurality of second vertical support rods 25 are fixedly connected to the peripheral side of the upper end of the first horizontal installation plate 22, and the upper end of the second vertical support rods 25 is connected to the second horizontal installation plate 24;

[0102]A plurality of first support blocks ...

Embodiment 3

[0109] On the basis of Example 2, as figure 2 As shown, the lift driving member 28 is: a hydraulic cylinder or an air cylinder; the upper end of the second vertical support rod 25 slides through the second horizontal mounting plate 24;

[0110] The flat plate straightening device 2 also includes:

[0111] A plurality of first springs 26 are in one-to-one correspondence with a plurality of second vertical support rods 25, and both ends of the first springs 26 are respectively fixedly connected to the first horizontal mounting plate 22 and the second horizontal mounting plate 24;

[0112] Two sets of drive groups 29 are symmetrically arranged in the straightening box 21, and are located on the left and right sides of the correcting plate (210);

[0113] The drive group 29 includes:

[0114] The first horizontal rotating shaft 291 is arranged in the front-rear direction, and a first driving motor is arranged in the straightening box 21 to drive the rotation of the first horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com