High-efficiency silicon polishing equipment for diode production

A diode and high-efficiency technology, which is applied in the field of high-efficiency diode production silicon polishing equipment, can solve the problems that affect the processing efficiency, the position of the workpiece cannot be adjusted after the workpiece is fixed, and the workpiece falls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

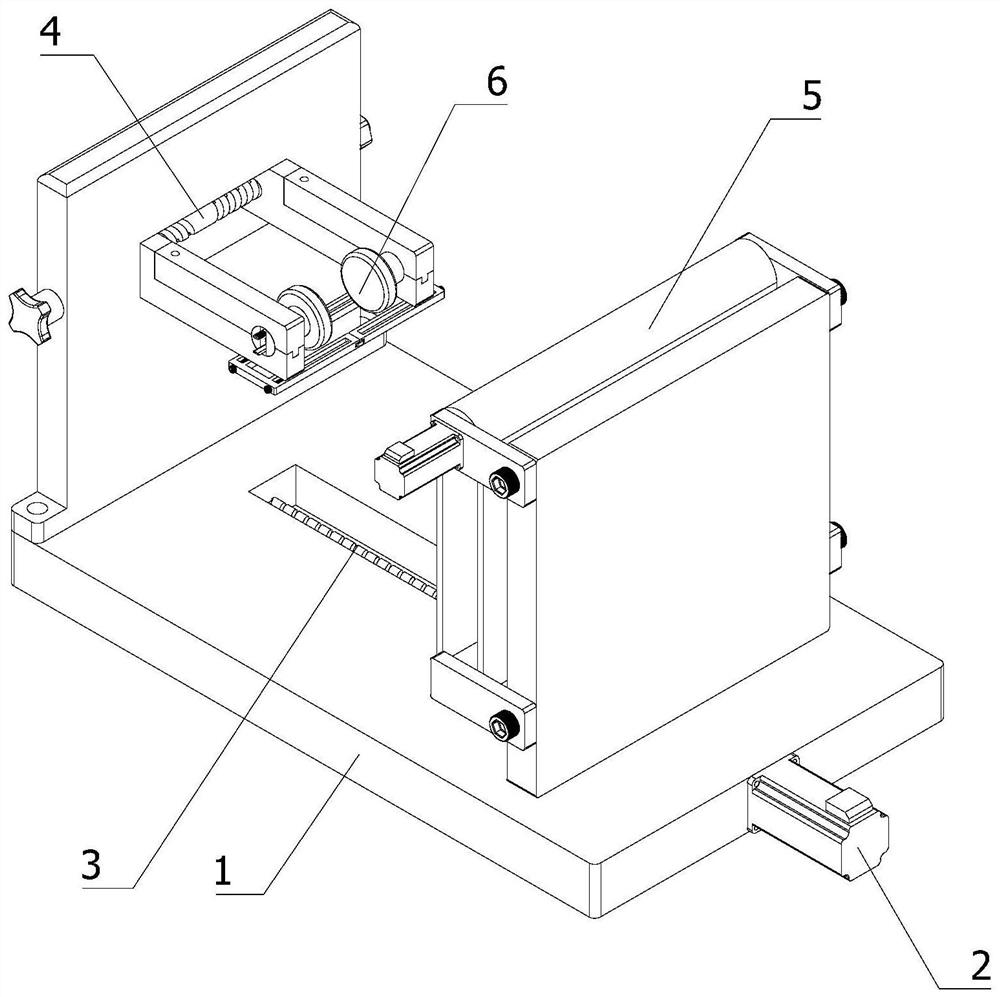

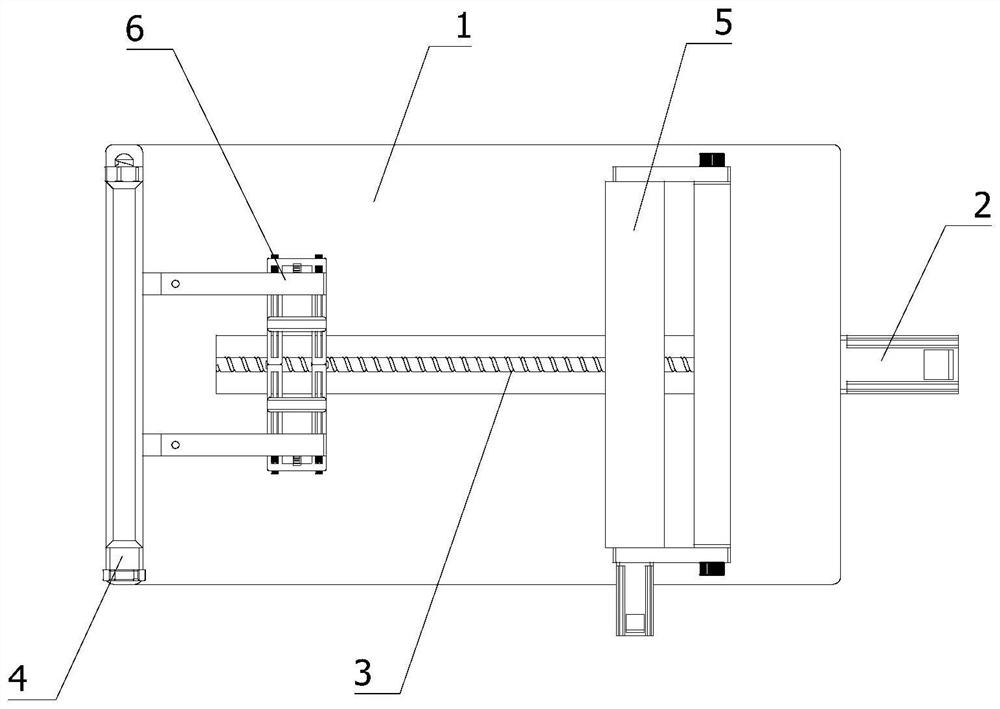

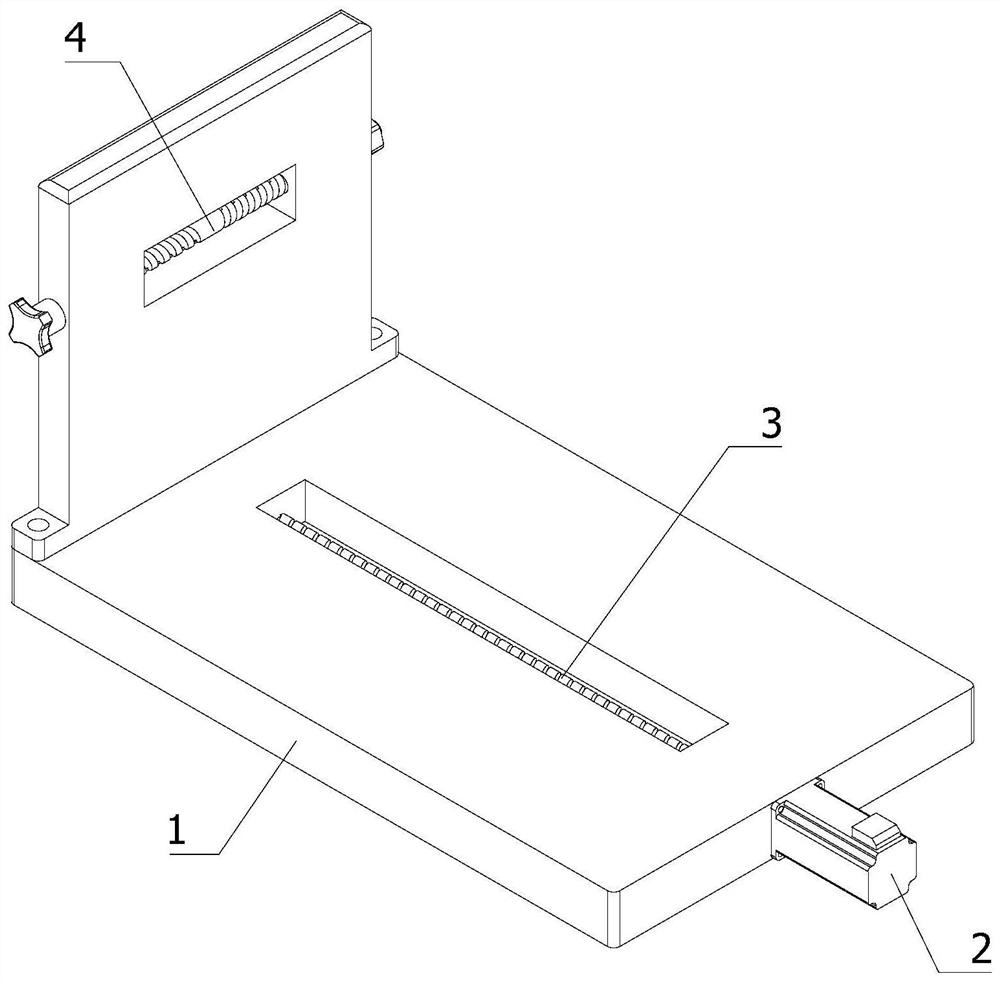

[0044] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0045] like Figure 1 to Figure 10 As shown, this application provides:

[0046]A silicon polishing equipment for high-efficiency diode production, comprising a base 1, a drive motor 2, a first threaded rod 3, a second threaded rod 4, a polishing device 5 and a fixing device 6, the fixing device 6 includes a fixing plate 6a, a fixing plate 6b , the positioning bar 6c, the positioning block 6d and the first spring 6e, the main surface of the fixed plate 6b is provided with a cylindrical protrusion 6b1, the cylindrical protrusion 6b1 is arranged coaxially with the fixed disk 6b, and the cylindrical protrusion 6b1 is away from the end of the fixed disk 6b It is rotatably arranged on the fixed plate 6a, and the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com