Noise-reduction buffer mechanism for sewing machine backstitch

A buffer mechanism, sewing machine technology, applied in sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems of nut impact, precision drop, loud noise, etc., and achieve the effect of prolonging service life, reducing parts wear, and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

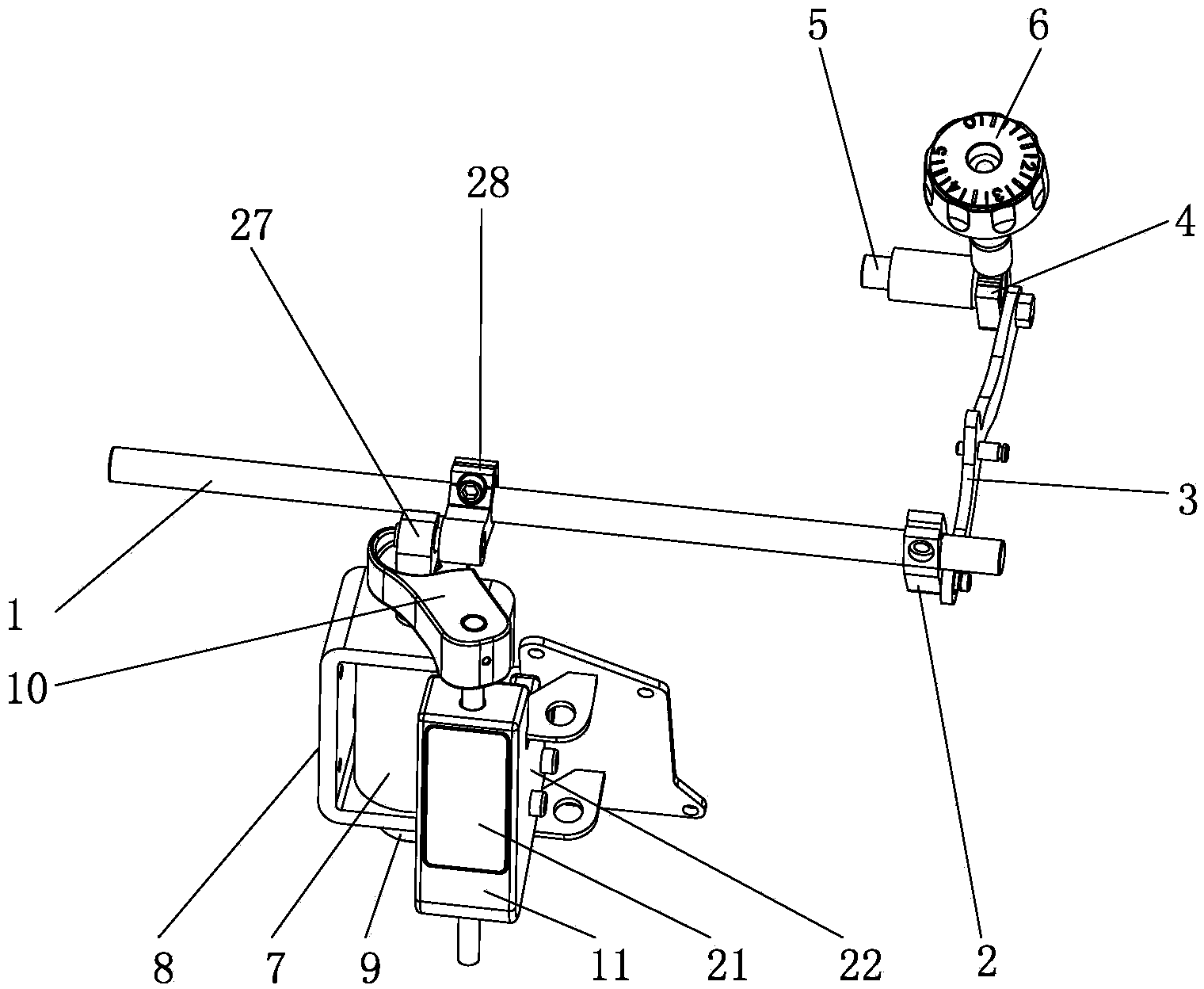

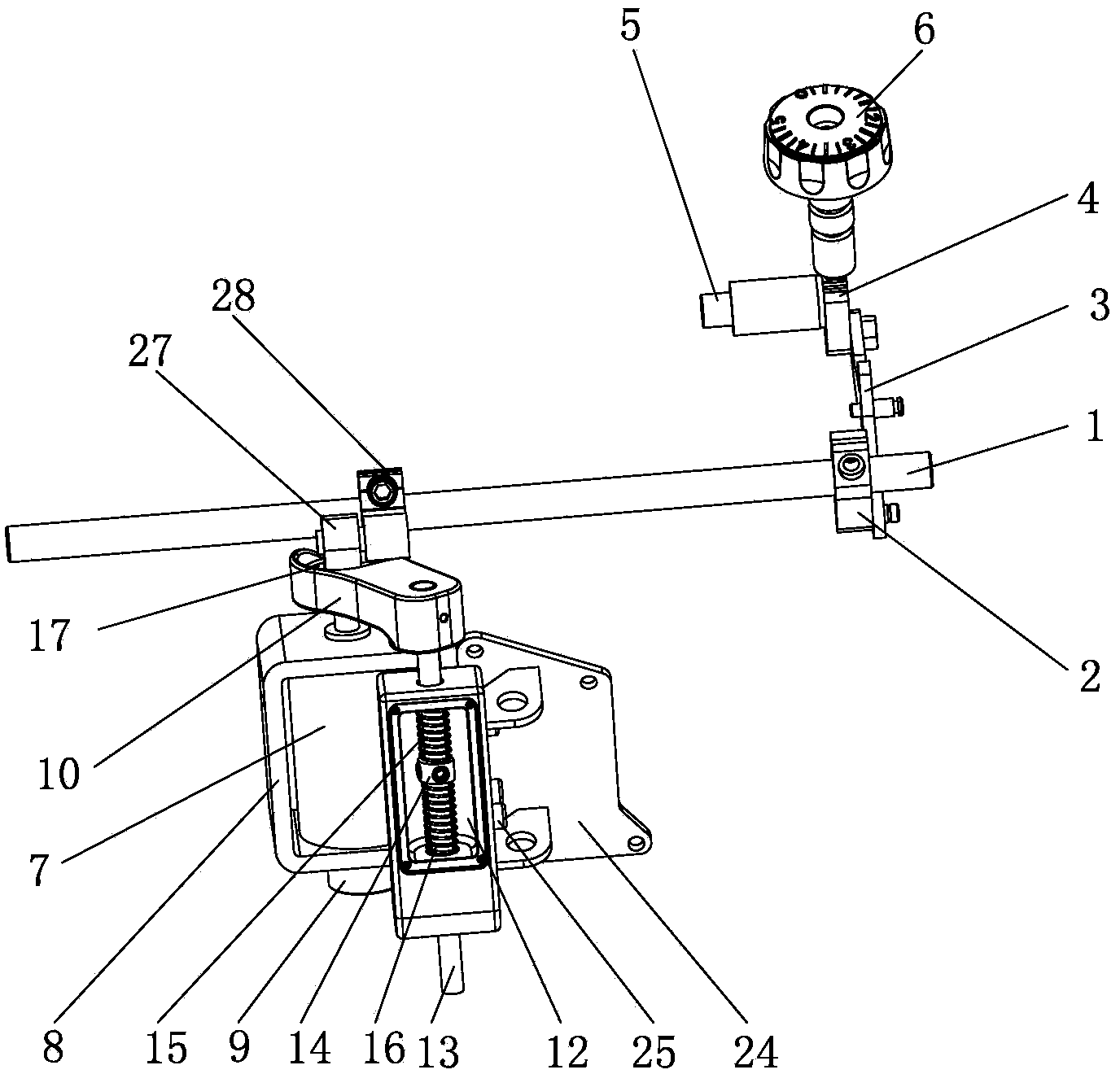

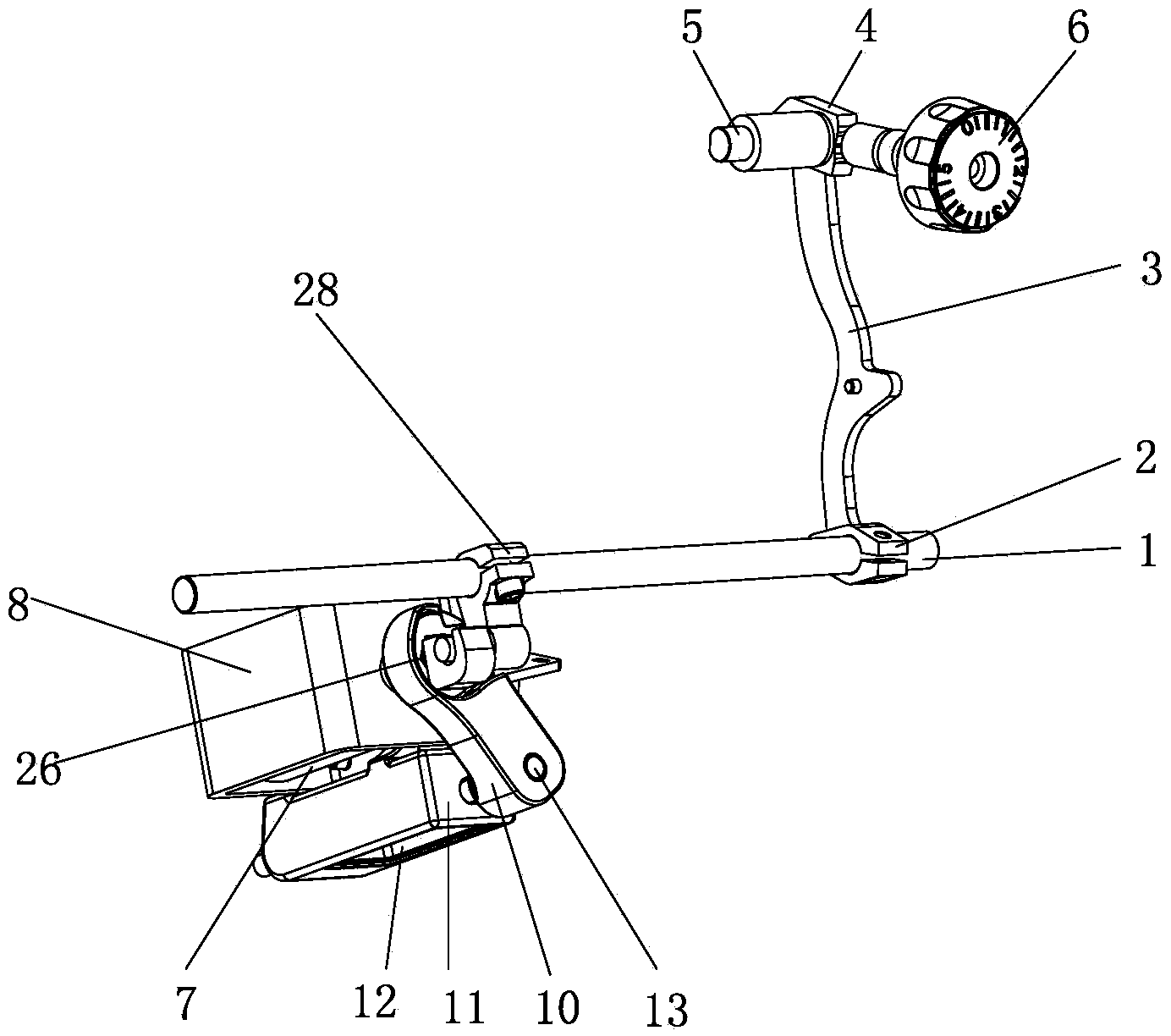

[0026] The present invention will be further described below with specific embodiment, see figure 1 -9:

[0027] A noise-reducing buffer mechanism for reverse sewing of a sewing machine, including a stitch length adjustment mechanism, the stitch length adjustment mechanism includes a feed adjustment shaft 1, the feed adjustment shaft 1 is connected to one end of a feed swing rod 3 through a feed adjustment crank 2, and the feed swing rod The other end of 3 is connected with the feed regulator 4, and the feed regulator 4 is set on the pin shaft 5 of the feed regulator. One side of the feed regulator 4 is provided with a feed adjustment knob 6, and the backstitch electromagnet is set on the feed adjustment shaft 1. On one side, the backstitch electromagnet includes a shell 7 and a frame 8 arranged outside the shell 7, a coil is arranged inside the shell 7, an iron core 9 is penetrated in the shell 7 and the head and the tail extend out of the frame respectively 8, the head of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com