Small nuclear magnetic resonance loading and unloading equipment

A technology of nuclear magnetic resonance and loading and unloading equipment, which is applied in the direction of transportation, packaging, and manual conveying devices. Drop damage, avoid sliding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. The following embodiments are only for illustrative purposes and are not intended to limit the scope of the present invention.

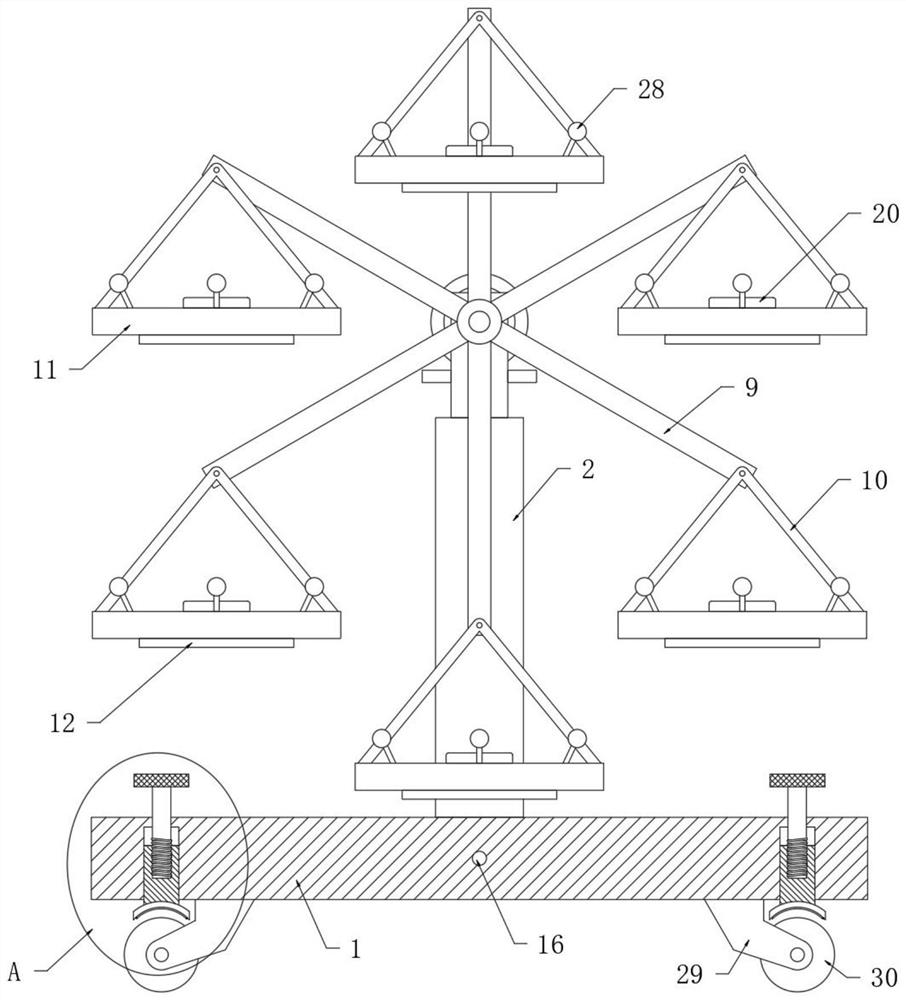

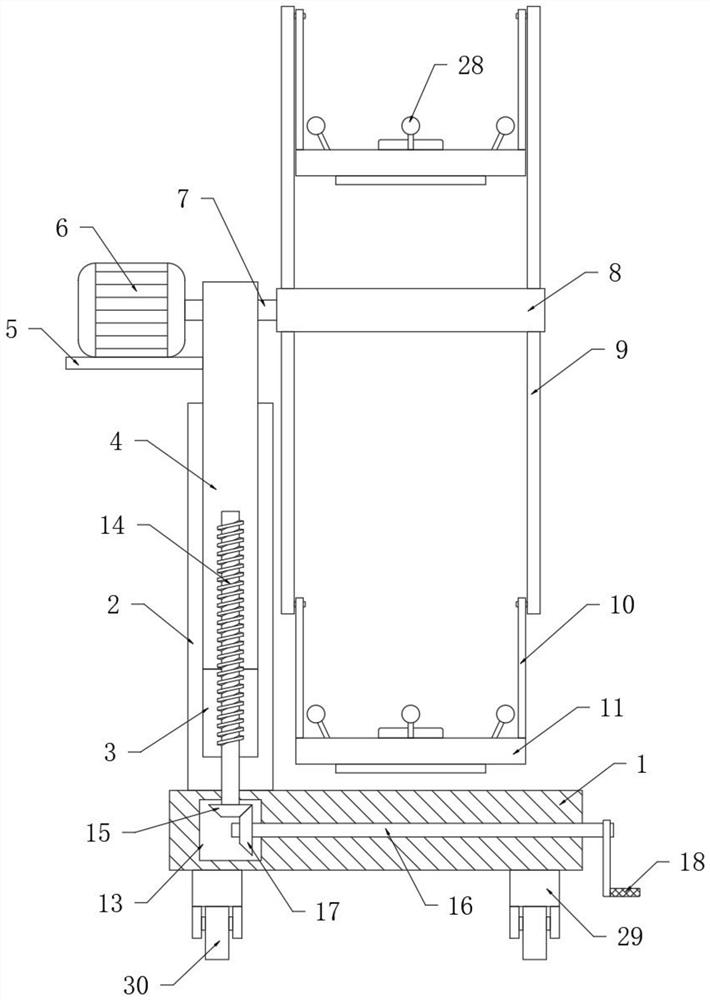

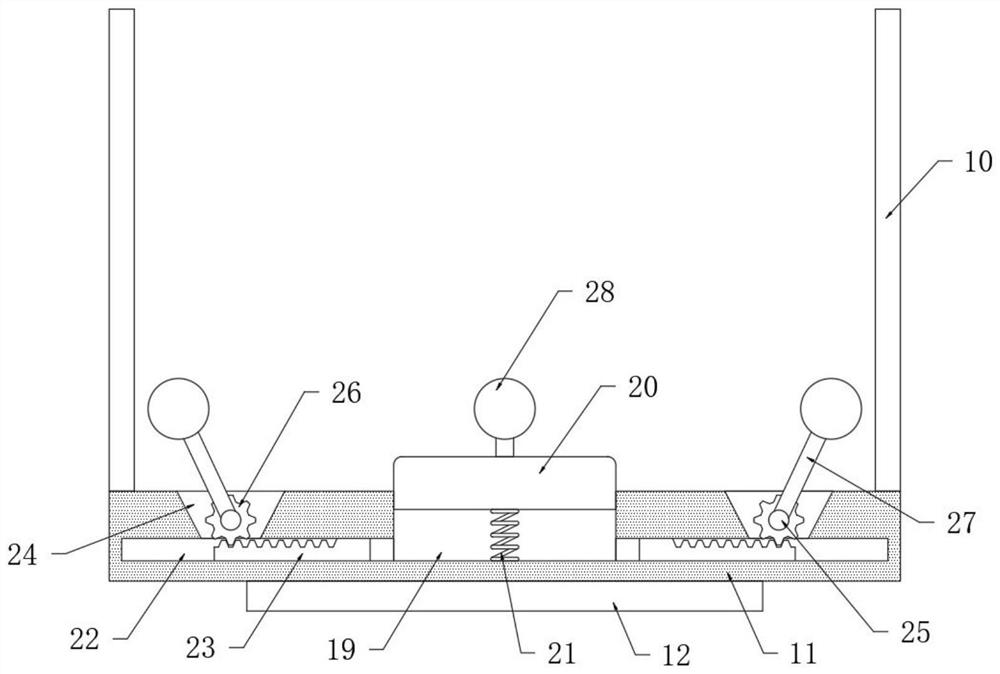

[0024] refer to Figure 1-4 , a small nuclear magnetic resonance loading and unloading equipment, comprising a support base plate 1, a support column 2 is fixedly connected to the side of the support base plate 1 at the center position, a lift slot 3 is opened on the support column 2, and a lift column 4 is slidably connected in the lift slot 3 , the upper end of the lifting column 4 is connected with a main shaft 7 through rotation, one end of the main shaft 7 is coaxially fixedly connected with a fixed cylinder 8, and the two ends of the fixed cylinder 8 are fixedly connected in a circular array. 9. One end away from the fixing cylinder 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com