Mortar material for repairing thin layer of road surface and construction technology

A technology of mortar material and construction technology, which is applied in the direction of roads, roads, pavement details, etc., can solve problems such as uneven potholes on the road surface, and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

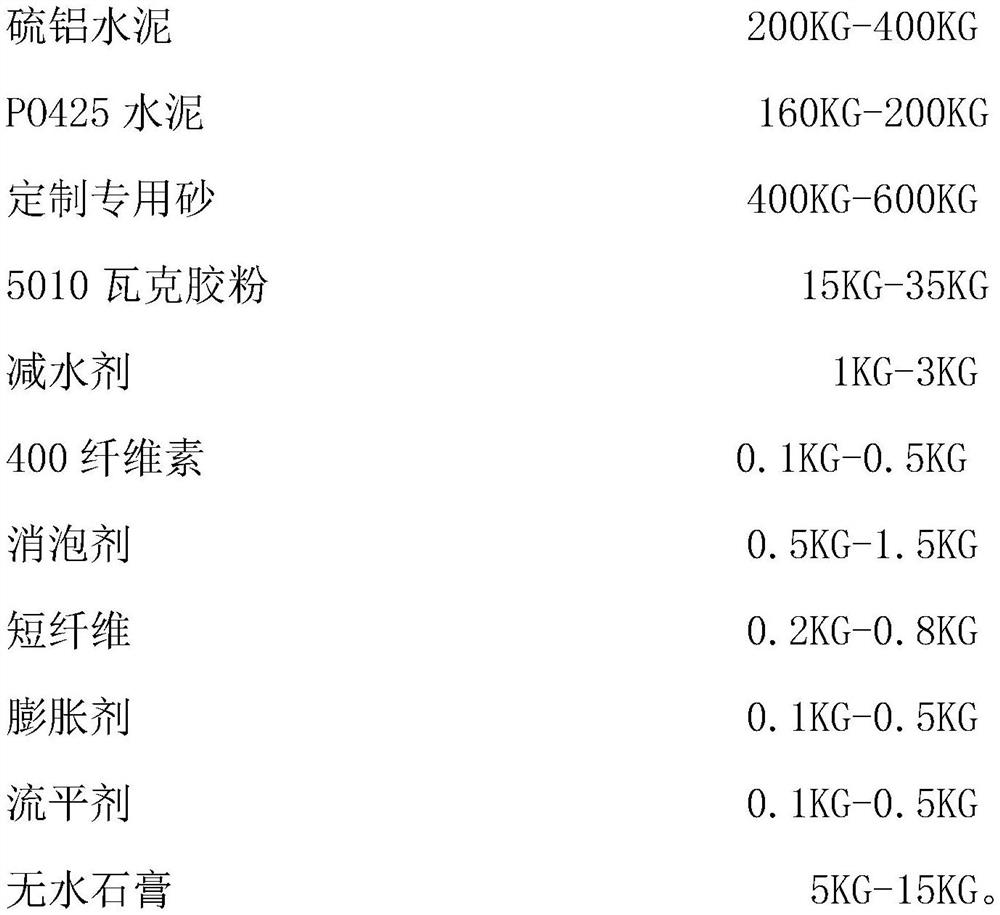

[0026] Embodiment 1, the mortar material used for the repair of the thin layer of the road surface is proportioned according to the following raw materials:

[0027]

[0028]

[0029] Wherein, the construction process of the mortar material for repairing the thin layer of road surface is carried out according to the following steps:

[0030] Step 1: First, mix the mortar materials on site according to the above raw materials;

[0031] Step 2: Remove the loose parts of the ground and clean them with a broom to ensure that there are no visible stones and dust on the construction surface;

[0032] Step 3: Rinse the ground several times with water, make sure the ground is full of water, but there should be no clear water during construction, and no air bubbles should be generated during construction;

[0033] Step 4: Brush Zhonglei brand ground interface agent one or two times;

[0034] Step 5: Add about 4.5 kg of water according to one bag of materials, and the phenomenon...

Embodiment 2

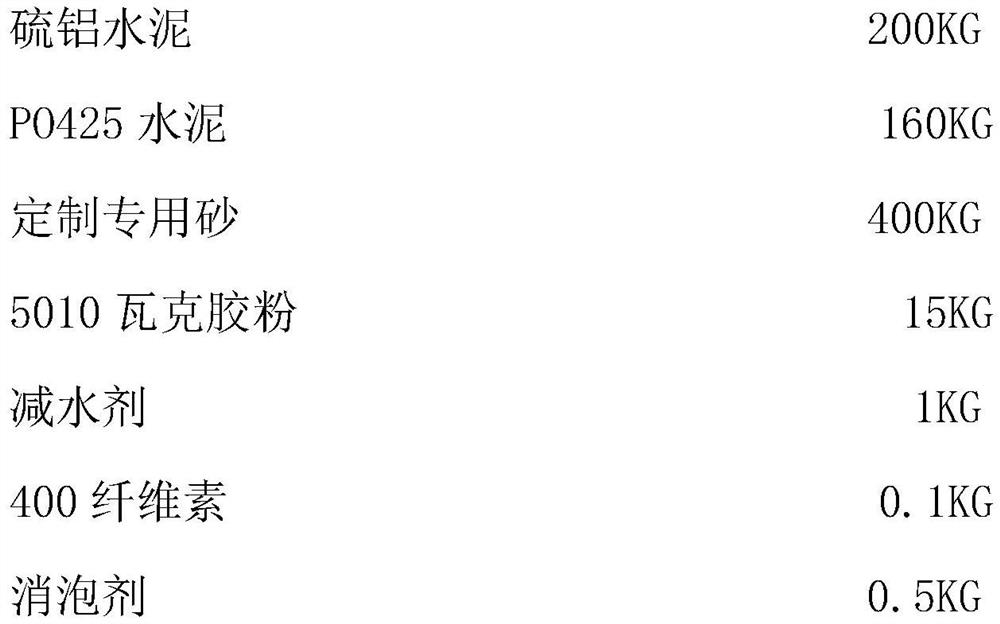

[0037] In the second embodiment, the mortar material used for the repair of the thin layer of the road surface is proportioned according to the following raw materials:

[0038]

[0039] Wherein, the construction process of the mortar material for repairing the thin layer of road surface is carried out according to the following steps:

[0040] Step 1: First, mix the mortar materials on site according to the above raw materials;

[0041] Step 2: Remove the loose parts of the ground and clean them with a broom to ensure that there are no visible stones and dust on the construction surface;

[0042] Step 3: Rinse the ground several times with water, make sure the ground is full of water, but there should be no clear water during construction, and no air bubbles should be generated during construction;

[0043] Step 4: Brush Zhonglei brand ground interface agent one or two times;

[0044] Step 5: Add about 4.5 kg of water according to one bag of materials, and the phenomenon...

Embodiment 3

[0047] Embodiment 3, the mortar material that is used for thin layer repair of road surface is proportioned according to the following raw materials:

[0048]

[0049] Wherein, the construction process of the mortar material for repairing the thin layer of road surface is carried out according to the following steps:

[0050] Step 1: First, mix the mortar materials on site according to the above raw materials;

[0051] Step 2: Remove the loose parts of the ground and clean them with a broom to ensure that there are no visible stones and dust on the construction surface;

[0052] Step 3: Rinse the ground several times with water, make sure the ground is full of water, but there should be no clear water during construction, and no air bubbles should be generated during construction;

[0053] Step 4: Brush Zhonglei brand ground interface agent one or two times;

[0054] Step 5: Add about 4.5 kg of water according to one bag of materials, and the phenomenon of floating and wa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap