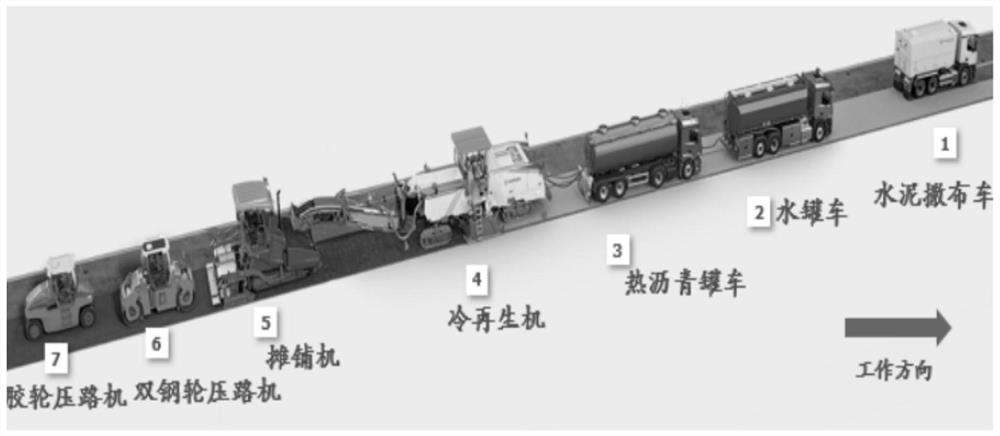

Milling, mixing, paving and compacting method for synchronous paving cold in-place recycling

A technology of cold regeneration and milling, which is applied in the fields of milling, mixing, paving and compaction of synchronous paving and in-situ cold regeneration, which can solve the problem of limited application and development, failure to improve construction efficiency, and easy segregation on the surface of the regeneration layer And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

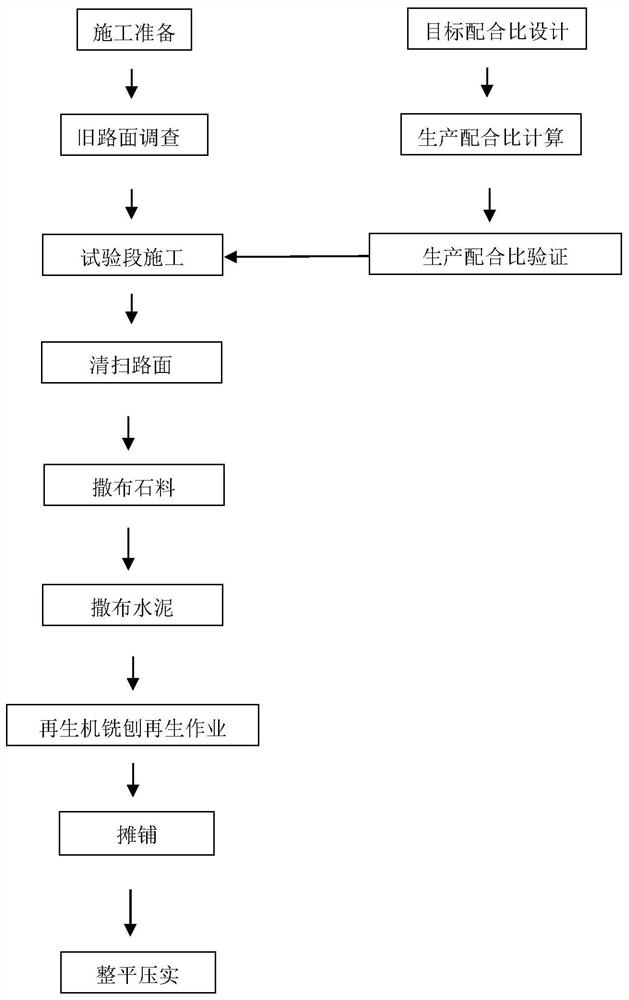

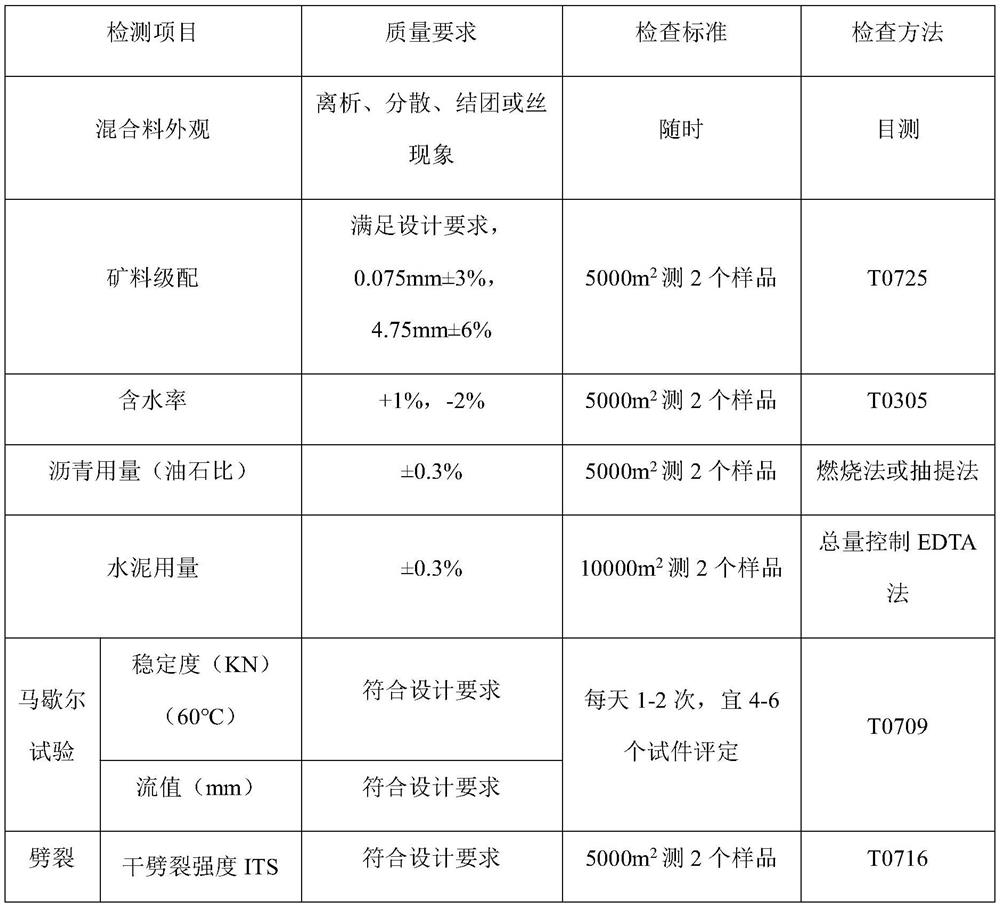

[0032] Specific construction steps:

[0033] As a kind of embodiment of the present application, the formula of the regenerative mixture that the present embodiment adopts is as follows:

[0034] The application's high-performance foamed asphalt cold recycled mixture in situ, the raw materials of the mixture include a first group of materials and a second group of materials, and the first group of materials includes: 18 parts by weight of new aggregate (new aggregate is selected Gravels with a particle size of 9.5-26.5mm), 1.8 parts by weight of cement, and 80.2 parts by weight of recycled asphalt mixture; the sum of the materials in the first group of materials is 100 parts by weight; the second group of materials includes: Foamed asphalt, mixing water, described foamed asphalt is 2.4 parts by weight (the weight part of this foamed asphalt is when calculating with the first group of materials as a whole 100 parts, corresponding to the weight part of foamed asphalt), described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com