Activated waste rubber powder noise reduction micro-surfacing mixture

A technology of micro-surfacing mixture and waste rubber powder, which is applied in the field of activated waste rubber powder noise-reducing micro-surfacing mixture, which can solve the problem of inability to effectively reduce the driving noise of preventive maintenance and sealing vehicles, and does not consider the interaction between rubber powder and asphalt. Problems such as capacitive and adhesive properties, unable to quickly restore traffic, etc., to achieve rapid opening of traffic, high and low temperature performance and durability, and increase the effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

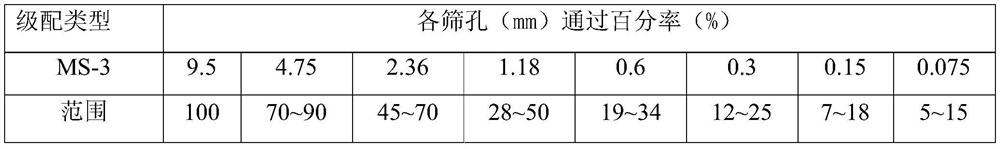

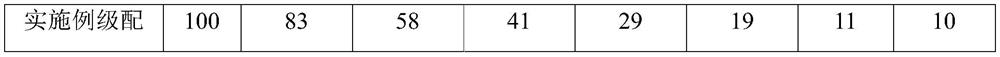

[0024] In this embodiment, the activated waste rubber powder noise-reducing micro-surface mixture, the raw materials include the following components by weight: 100 parts of mineral material, 7 parts of modified emulsified asphalt, 1 part of activated waste rubber powder, 2 parts of cement, octadecane 0.5 parts of trimethylammonium chloride, 0.5 parts of composite additives, and 5 parts of water.

[0025] In this embodiment, the water-based epoxy resin is composed of water-based epoxy resin and water-based curing agent, and the water-based epoxy accounts for 5% of the mass percentage of pure asphalt; the mass percentage of the styrene-butadiene rubber accounted for pure asphalt is 1% The activated waste rubber powder is waste tire rubber powder, the particle size of which is a mixture of 50 mesh and 60 mesh, and the weight ratio of the two is 1:1; the waste rubber powder is processed in the following way: the waste rubber powder is placed In a microwave oven with a power of 50...

Embodiment 2

[0029] The activated waste rubber powder noise-reducing micro-surfacing mixture of this embodiment, the raw materials include the following components by weight: 100 parts of mineral material, 11 parts of modified emulsified asphalt, 3 parts of activated waste rubber powder, 3 parts of cement, 18 parts 1.5 parts of alkyltrimethylammonium chloride, 1 part of composite additive;

[0030] In the present embodiment, the water-based epoxy resin is composed of water-based epoxy resin and water-based curing agent, and the water-based epoxy accounts for 30% by mass of pure asphalt; the mass percent of styrene-butadiene rubber accounted for pure asphalt is 5% ; The activated waste rubber powder is waste tire rubber powder, and its particle size is a mixture of 40 mesh and 70 mesh (the mass ratio of the two is 1:1); the waste rubber powder is processed in the following way: the waste rubber powder Place it in a microwave oven with a power of 700W, and the radiation time is 100s.

[003...

Embodiment 3

[0034] The activated waste rubber powder noise-reducing micro-surfacing mixture of this embodiment, the raw materials include the following components by weight: 100 parts of mineral material, 7 parts of modified emulsified asphalt, 3 parts of activated waste rubber powder, octadecyl trimethyl 1.5 parts of ammonium chloride, 0.5 parts of composite additives;

[0035] In this embodiment, the water-based epoxy resin is composed of water-based epoxy resin and water-based curing agent, and the water-based epoxy accounts for 5% of the mass percent of pure asphalt; the mass percent of the pure asphalt accounted for by the styrene-butadiene rubber is 5% ; The activated waste rubber powder is waste tire rubber powder, and its particle size is a mixture of 35 mesh, 45 mesh, and 80 mesh (the mass ratio of the three is 1:1:1); the waste tire rubber powder is processed in the following manner : Place the waste rubber powder in a microwave oven with a power of 900W, and the radiation time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com