Construction method of open-graded drainage type epoxy asphalt ultrathin anti-skid wearing layer

A technology of epoxy asphalt and construction method, which is applied in the directions of roads, pavement details, gutter/curbstone, etc. The effect of sliding performance, short construction time and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

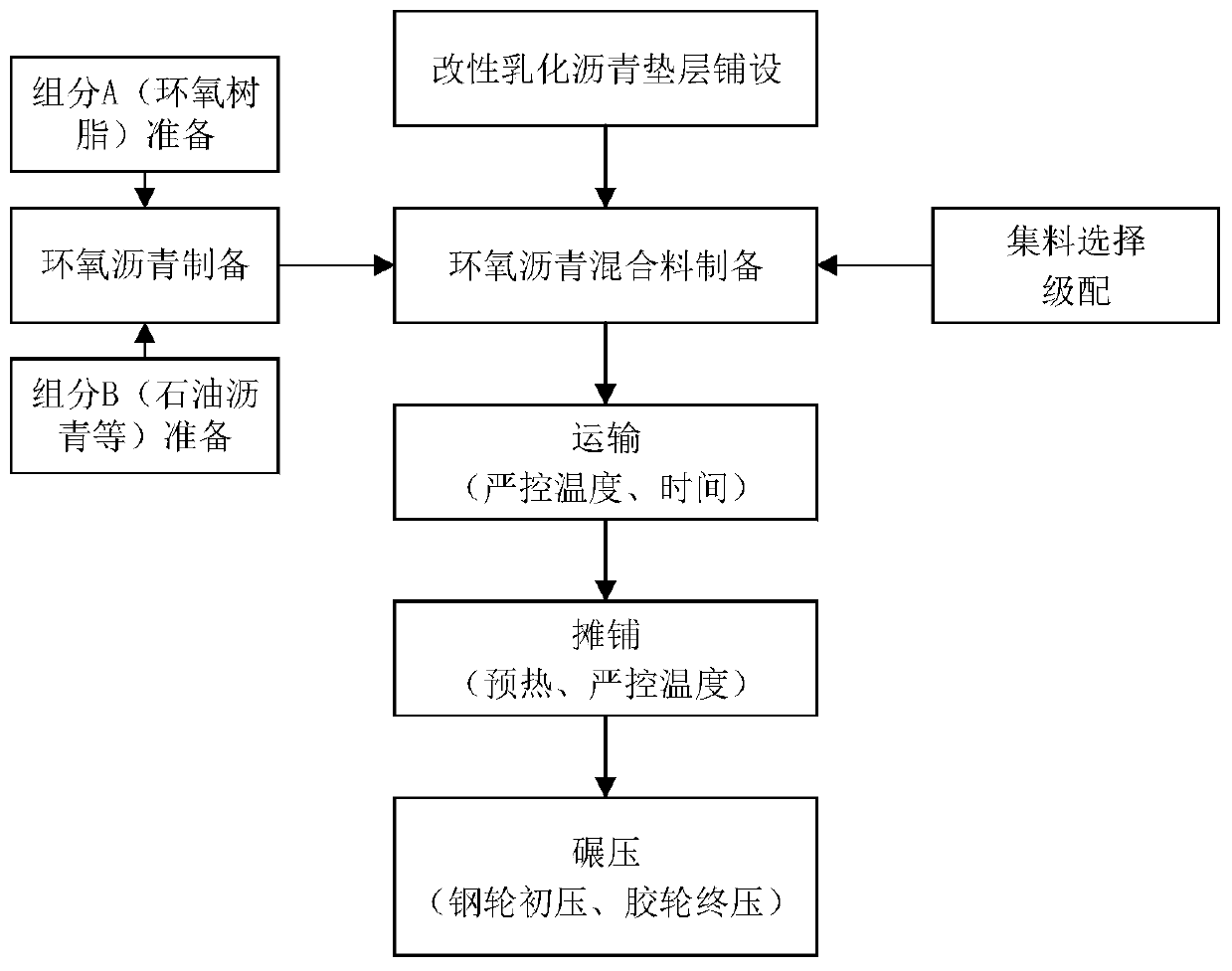

[0028] see figure 1 , the overall flow of the construction method of the open-graded drainage type epoxy asphalt ultra-thin wear layer of the present invention is shown in the figure.

[0029] Step 1 Surface interlayer treatment: 12 hours before the wear layer is paved, clean the pavement surface and spray a layer of modified emulsified asphalt mixed with rubber on the surface of the densely graded asphalt concrete layer, at a rate of 0.5L / m 2 Sprinkle, fully break demulsification and play the role of high adhesion and water sealing.

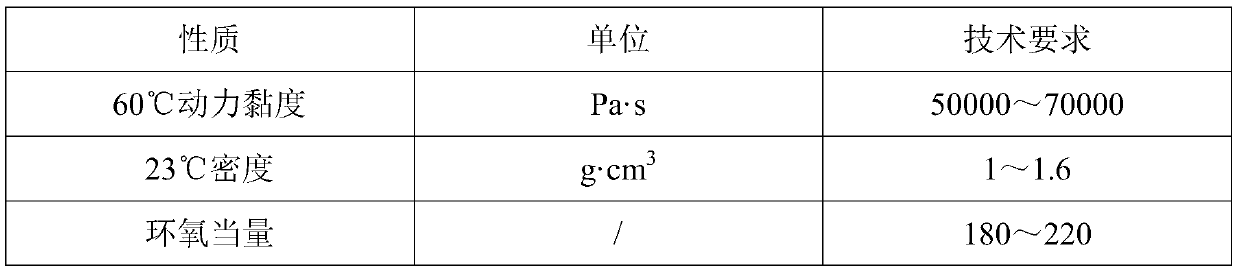

[0030] Step 2: Prepare epoxy asphalt: take epoxy resin as component A, and form component B with 98.7% petroleum asphalt, 0.4% acid anhydride curing agent, and 0.9% TPS high viscosity modifier. The component A is heated to 55° C., the component B is heated to 120° C. and then stirred evenly according to the content of the component A being 38%, to obtain an epoxy asphalt cement for use. The properties of the samples were measured as:

[0031]...

Embodiment 2

[0039] Step 1 Surface interlayer treatment: 12 hours before the wear layer is paved, clean the pavement surface and spray a layer of modified emulsified asphalt mixed with rubber on the surface of the densely graded asphalt concrete layer, at a rate of 0.5L / m 2 Sprinkle, fully break demulsification and play the role of high adhesion and water sealing.

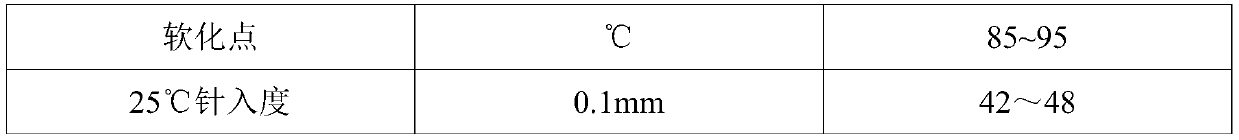

[0040] Step 2: Prepare epoxy asphalt: take epoxy resin as component A, and form component B with 99% petroleum asphalt, 0.3% acid anhydride curing agent, and 0.7% TPS high viscosity modifier. The component A is heated to 60° C., the component B is heated to 120° C. and then stirred evenly according to the content of the component A at 45%, to obtain an epoxy asphalt binder for later use. The properties of the samples were measured as:

[0041] nature unit test value 60℃ dynamic viscosity Pa·s 65000 23℃ density g cm 3

1.32 epoxy equivalent / 205 Softening Point ℃ 90 Penetrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com