Preparation method and application of composite modified cement repairing material

A technology of compound modification and repair material, which is applied in the field of preparation of compound modified cement repair material, can solve problems such as affecting traffic flow and long open traffic time, and achieves delaying diffusion and spreading, short curing time, and improving diffusion and spreading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

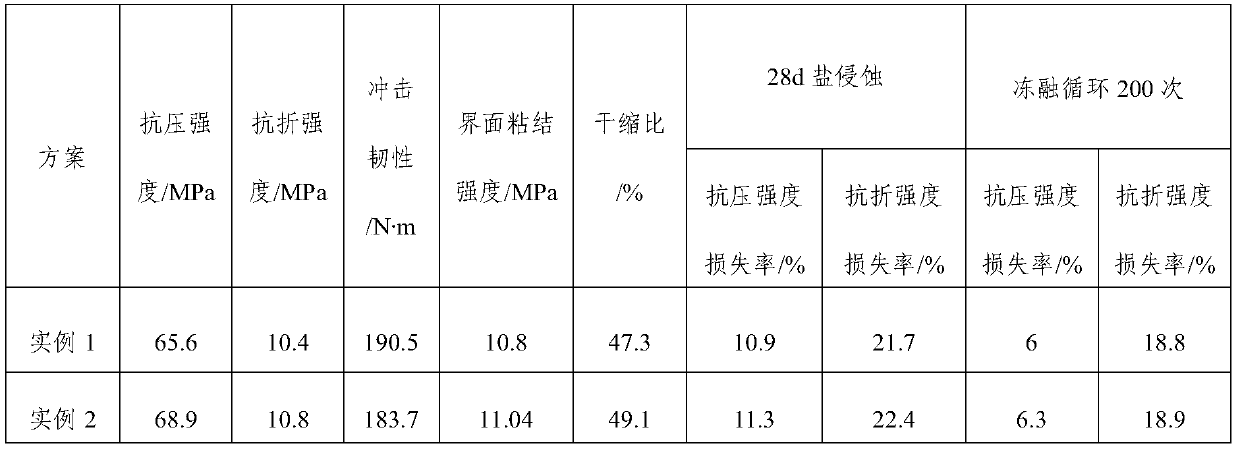

Examples

Embodiment 1

[0039] (1) Take out the 4.75mm fine aggregate with a standard sieve, dry it in an oven at 80°C and set it aside;

[0040] (2) Ratio of materials: Weigh 93 parts of 42.5-grade rapid-hardening sulfoaluminate cement, 0.1 part of polypropylene fiber, 5.5 parts of silica fume, 0.4 part of vinyl acetate dispersible latex powder, and FDN-C naphthalene-based high-efficiency water-reducing 0.9 parts of polysiloxane antifoaming agent, 0.1 part of polysiloxane defoamer, mix and stir evenly, 500 revolutions per minute, stirring time is 10 minutes, and the polymer cement mixture can be obtained;

[0041] (3) Take by weighing 12kg of polymer cement mixture, add 13kg of fine aggregate therein, mix and stir evenly, 500 revolutions per minute, stirring time is 10 minutes, can obtain mortar 25kg;

[0042] (4) Add 1.6 kg of water to the mortar, mix and stir evenly, 1000 revolutions per minute, and stir for 5 minutes to obtain a composite modified cement quick repair material.

Embodiment 2

[0044] Adopt the method of embodiment 1, the difference is that, the formula of polymer cement mixture is 93.3 parts of 42.5 grade quick-hardening sulfoaluminate cements, 0.07 parts of polypropylene fiber, 5.5 parts of silica fume, 0.4 parts of vinyl acetate dispersible latex powder parts, 0.9 parts of FDN-C naphthalene-based high-efficiency water reducer, and 0.1 parts of polysiloxane defoamer.

Embodiment 3

[0046]Adopt the method of embodiment 1, the difference is that, the formula of polymer cement mixture is 92.5 parts of 42.5 grade quick-hardening sulfoaluminate cements, 0.13 parts of polypropylene fiber, 5.7 parts of silica fume, 0.4 parts of vinyl acetate dispersible latex powder parts, 0.9 parts of FDN-C naphthalene-based high-efficiency water reducer, and 0.1 parts of polysiloxane defoamer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com