Additive feeding device and clothes processing device

A technology for adding devices and additives, applied in washing devices, other washing machines, textiles and paper making, etc., can solve the problems of too much or too little additives, inconvenient cleaning of the liquid storage box, fading of clothes, etc., to achieve rich application scenarios, Suitable for promotion and use, with remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

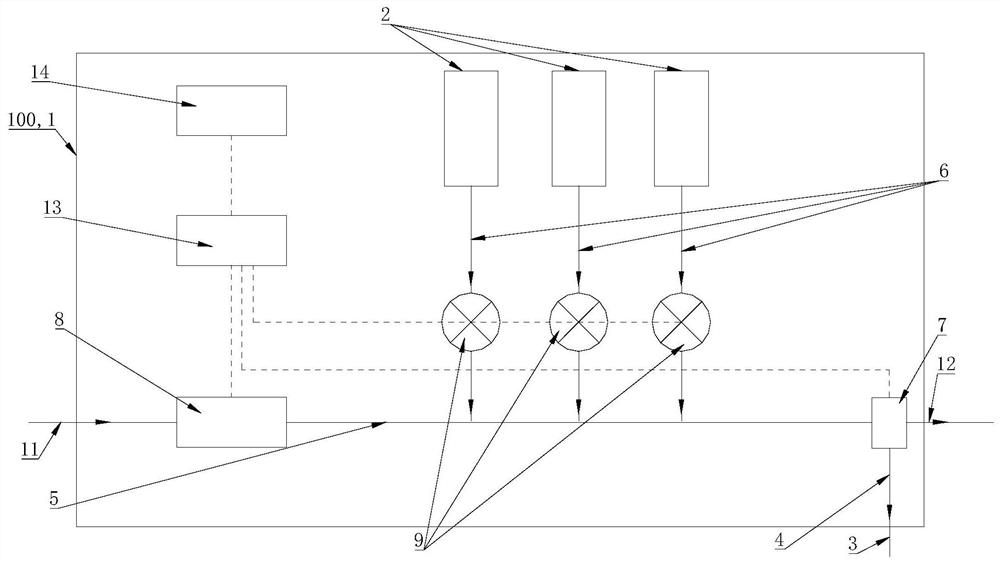

[0044] like Figures 1 to 3 As shown, an additive dispensing device is introduced in this embodiment, which includes,

[0045] The body 1, the body 1 constitutes an independent part;

[0046] The liquid storage box 2, which constitutes a sealed cavity for storing additives, is installed on the main body 1;

[0047] The liquid taking port 3 is located on the outside of the main body 1. The liquid taking port 3 is communicated with the sealed cavity of the liquid storage box 2 through the liquid taking pipeline 4. The liquid taking pipe is provided with a liquid taking control structure for controlling the on-off of the pipeline.

[0048] In this embodiment, the liquid taking control structure may be a control valve that controls the connection or disconnection of the pipeline, or a pump that conducts the pipeline during operation and closes the pipeline during stoppage.

[0049] like figure 1 As shown, in this embodiment, the main body 1 of the injection device 100 is provi...

Embodiment 2

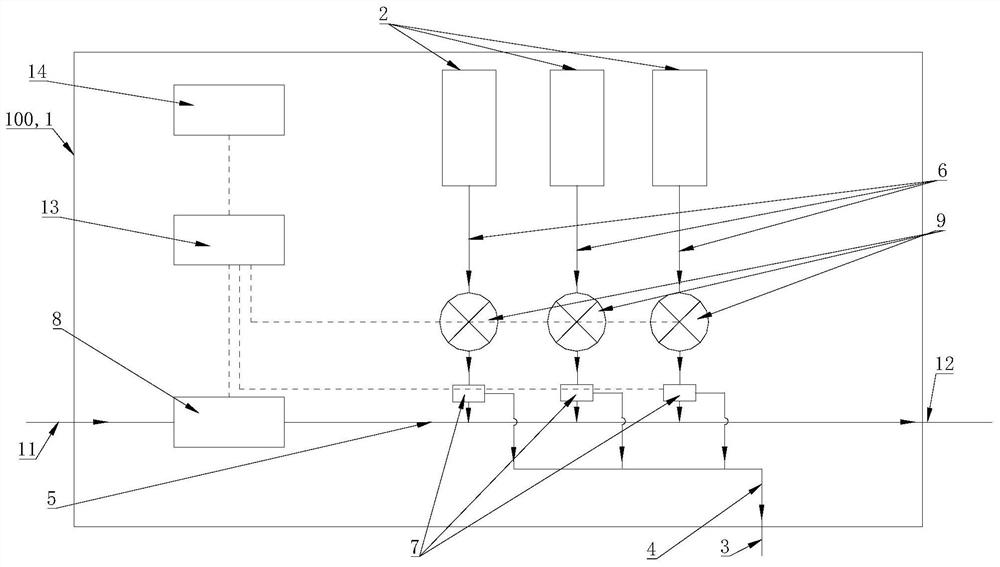

[0058] This implementation also has the following technical features based on the above-mentioned first embodiment:

[0059] like figure 1 As shown, in this embodiment, an additive dispensing device is introduced, which includes,

[0060] The body 1, the body 1 constitutes an independent part;

[0061] The liquid storage box 2, which constitutes a sealed cavity for storing additives, is installed on the main body 1;

[0062] The liquid taking port 3 is arranged on the outside of the main body 1 , and the liquid taking port 3 is communicated with the sealed cavity of the liquid storage box 2 through the liquid taking pipeline 4 .

[0063] like figure 1 As shown, in this embodiment, the body 1 of the additive injection device 100 is provided with a water supply channel 5, and the two ends of the water supply channel 5 are respectively connected with the water inlet 11 and the water outlet 12 provided on the body 1. The liquid outlet is communicated with the water supply wa...

Embodiment 3

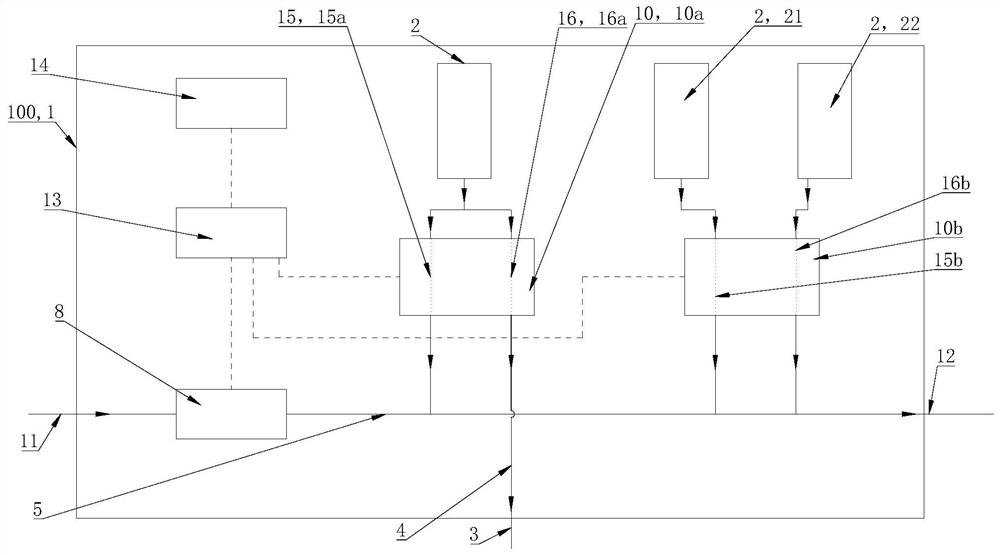

[0073] This embodiment also has the following distinguishing technical features based on the second embodiment above:

[0074] like image 3 As shown, in this embodiment, the suction device is a two-way pump 10a, and the two-way pump 10a has a first flow channel 15a and a second flow channel 16a that are respectively conducted when the impeller is reversed in forward and reverse directions. The inlet of the first flow channel 15a and the The inlet of the second flow channel 16a is connected with the liquid outlet of the liquid storage box 2, and the outlet of the first flow channel 15a and the outlet of the second flow channel 16a are connected with the water supply water channel 5 and the liquid intake port 3 respectively, so as to realize the utilization of The additives stored in the liquid storage box 2 of the dispensing device 100 can be used for hand washing or machine washing respectively.

[0075] In this embodiment, the bidirectional pump 10a has two working states: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com