Terahertz ultra-wideband light wall horn feed source and preparation method thereof

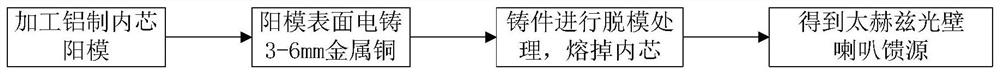

A horn feed and ultra-broadband technology, which is applied to waveguide horns, electrical components, and devices that enable antennas to work in different bands at the same time, can solve the problems of narrow frequency coverage, high processing costs, and high difficulty in processing horn feeds, and achieve Low processing cost, reduced input cost, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

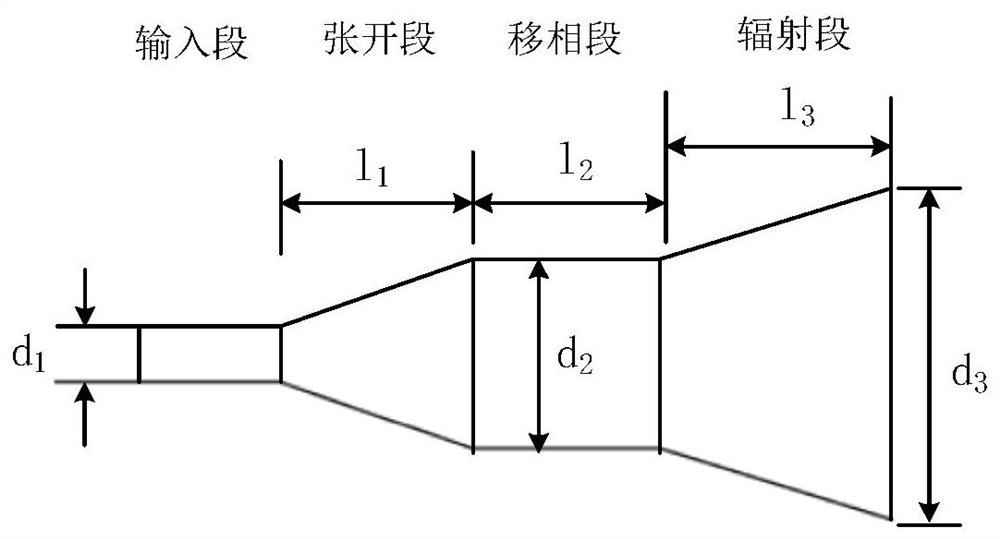

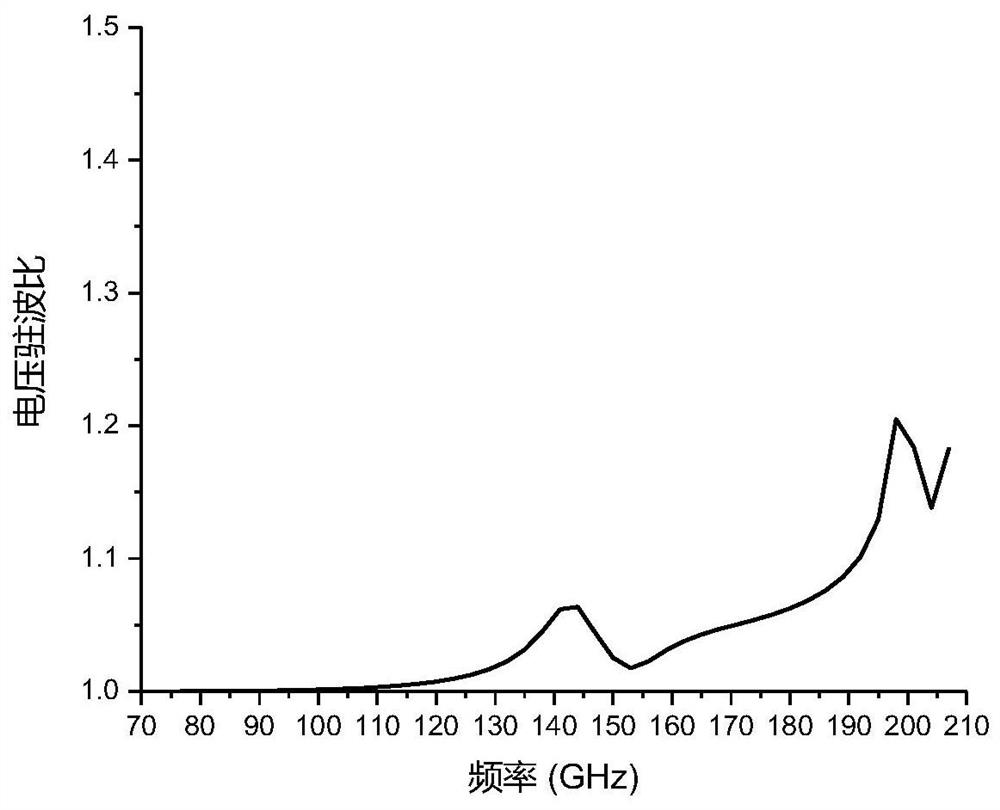

[0032] The terahertz ultra-broadband optical wall horn feed source of this embodiment is composed of an input section, an expansion section, a phase shift section and a radiation section, wherein the main transmission mode of the input section is TE 11 module, the function of the opening segment is to stimulate higher-order modules such as TE 12 Die, TE 13 Die, TM 11 Die and TM 12 mold. The function of the shifting segment is to adjust the phase between the modes. Due to TM 11 The mode only contributes to the E-plane pattern of the horn, and has no effect on the H-plane pattern, and through the correct design of the phase shift section, so in this embodiment, the horn mouth surface TE 11 and TM 11 The relative phase of the two modes reaches the optimum value, so that the E-plane and H-plane of the speaker are equalized. The function of the radiation section is to adjust the TE 11 Die, TE 12 Die, TE 13 Die, TM 11 Die and TM 12 The modulus ratio of the mode makes it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com