Auxiliary device for embedding steel sheet pile for pipe jacking construction

An auxiliary device, a technology for steel sheet piles, applied in sheet pile walls, infrastructure engineering, cleaning methods and appliances, etc., can solve the problems of steel sheet piles affecting the clearance size of shafts, sheet pile offsets, etc., to improve the scope of application and improve stability. The effect of stability and easy vertical clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

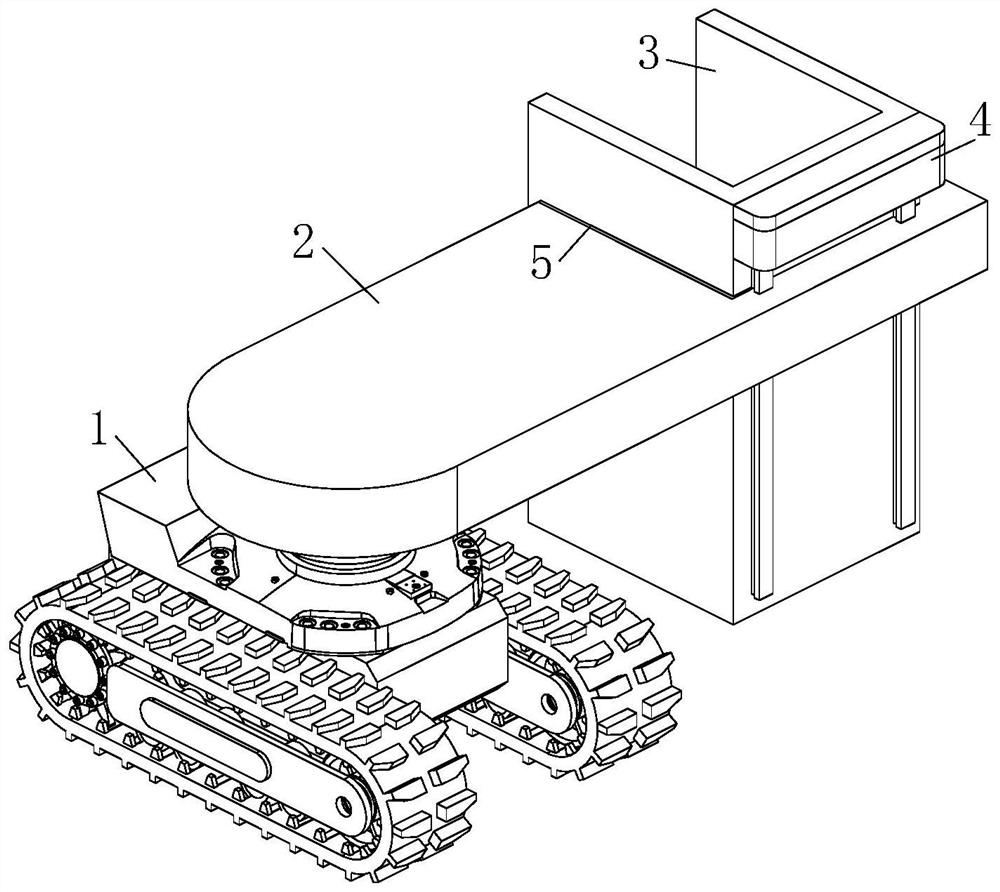

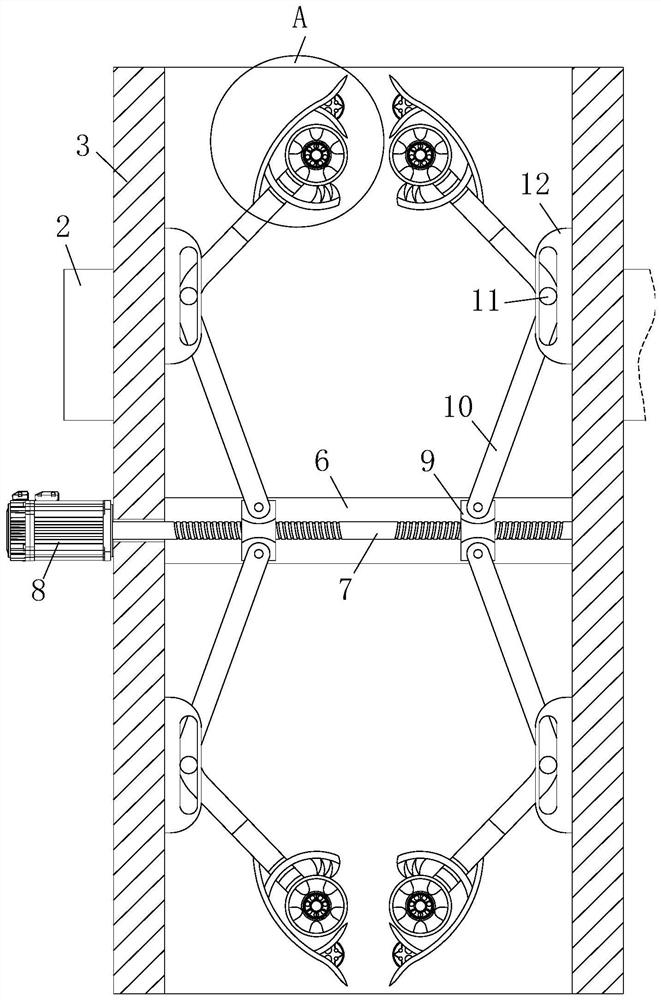

[0031] like figure 1 As shown, an auxiliary device for burying steel sheet piles for pipe jacking construction according to the embodiment of the present invention includes a crawler chassis 1, a beam 2, a C-shaped guide plate 3 and a lifting mechanism 4; the middle of the top surface of the crawler chassis 1 rotates A beam 2 is installed, and a notch 5 is opened on the side of one end of the beam 2 away from the crawler chassis 1, and a C-shaped guide plate 3 is slidably installed inside the notch 5. The C-shaped guide plate 3 and the inner wall of the notch 5 A lifting mechanism 4 is arranged between the pilings; during operation, the crawler chassis 1 moves to the position to be piled up, the motor drives the beam 2 to rotate, and drives the C-shaped guide plate 3 to move to the piling point. After the lifting mechanism 4 drives the C-shaped guide plate 3 to slide down , so that the C-shaped guide plate 3 touches the ground, the crane lifts the steel sheet pile to the middle ...

Embodiment 2

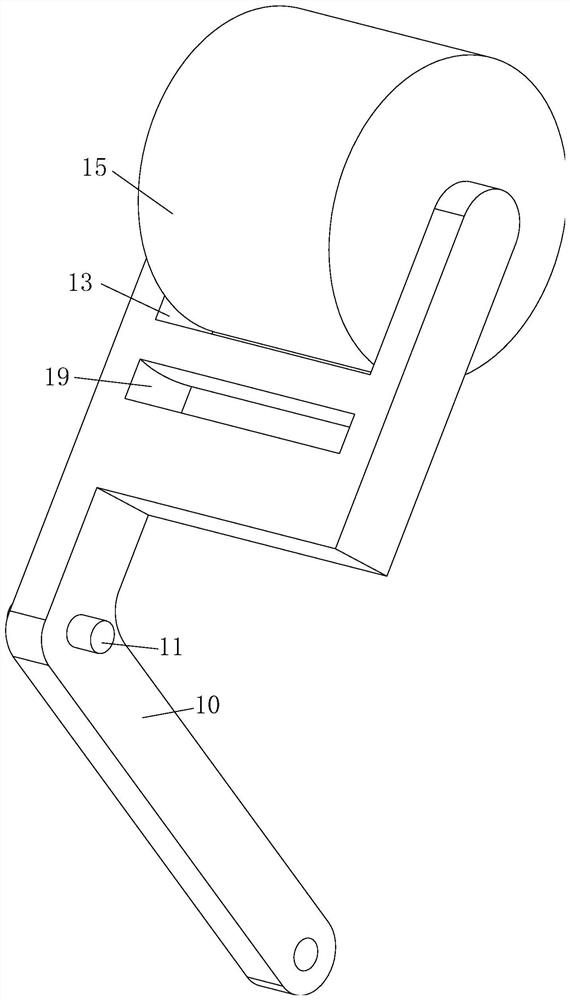

[0041] like Figure 8 As shown in the comparison example 1, another embodiment of the present invention is: the outer rings at both ends of the support rod 14 are fixed with helical blades 34, and the outer rings of the helical blades 34 are connected to the pressure roller 15. The inner ring is slidingly matched, and the outer wall of the spiral blade 34 is provided with fluff; during operation, the pressing wheel 15 rotates, so that the spiral blade 34 rotates against the inner wall of the pressing wheel 15, and pushes out the soil entering the pressing wheel 15, thereby improving the The degree of cleanliness inside the pinch roller 15.

[0042] When working: the crawler chassis 1 moves to the position to be piled, and the motor drives the beam 2 to rotate, driving the C-shaped guide plate 3 to move to the piling point, and the lifting mechanism 4 drives the C-shaped guide plate 3 to slide down so that the C-shaped guide plate 3 contacts To the ground, the crane hoists the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com