Return air utilization device

A cylinder and air pipe technology, applied in the field of return air utilization devices, can solve problems such as affecting processing efficiency, and achieve the effects of improving production and processing efficiency, ingenious and simple design, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

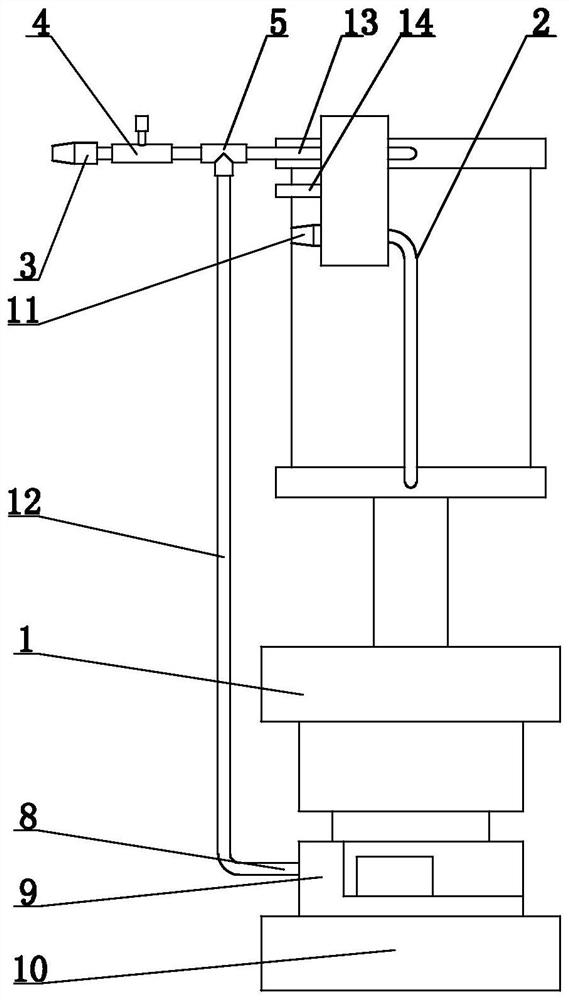

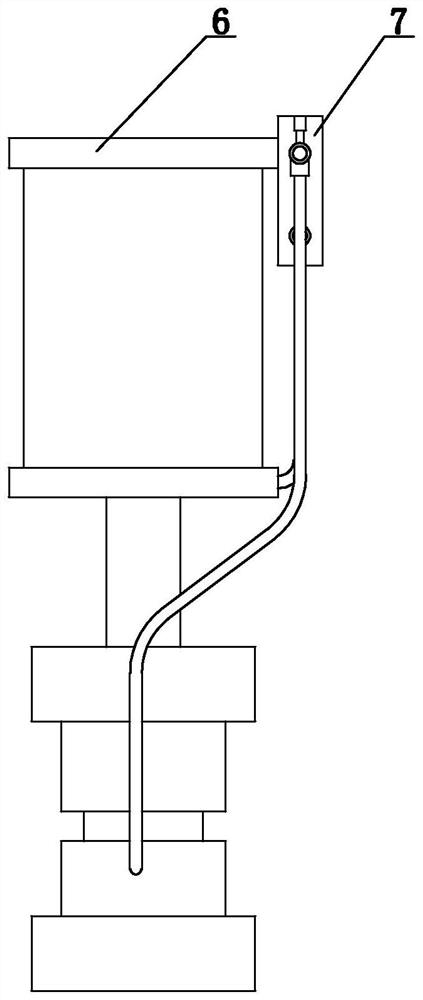

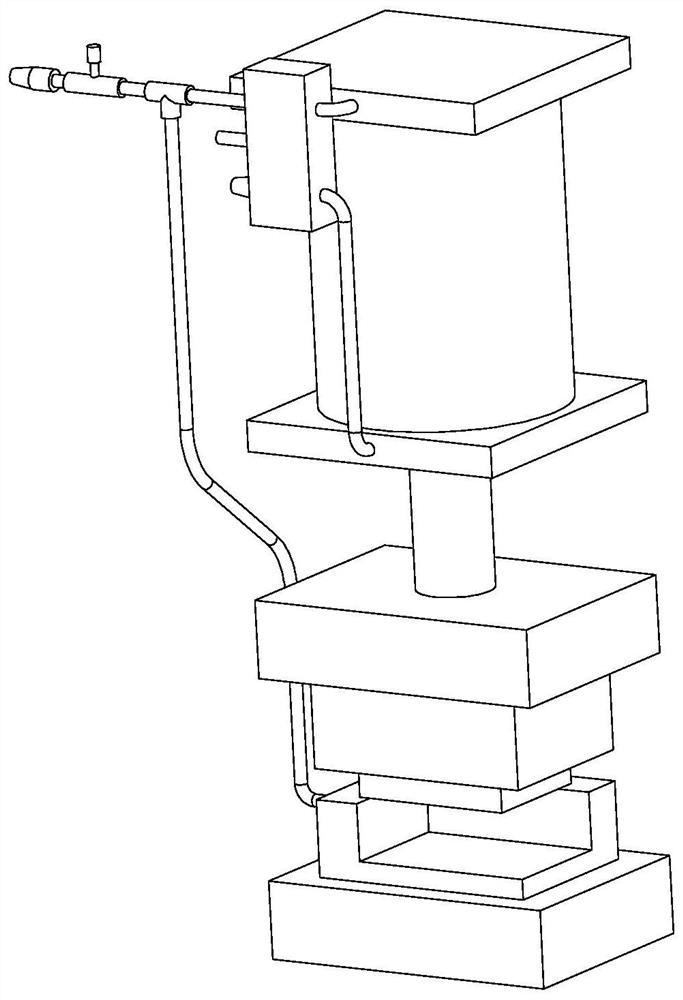

[0012] like figure 1 , 2 The air return utilization device shown in 3 and 3 includes a base, a tooling die 1, a cylinder 6 and an electromagnetic lock 7. The base 10 is provided with a workpiece seat 9, the workpiece seat 9 is provided with a tooling die 1, and the tooling die 1 is provided above. There is a cylinder 6, the upper side wall of the cylinder 6 is provided with a solenoid valve 7, the cylinder 2 is connected to the upper part of the solenoid valve 7 through the trachea a13, the trachea a13 is provided with a three-way joint 5, and the three-way joint 5 includes a port, b port and c port. a13 passes through the a port and the c port, the air pipe a13 on the a port side is connected to the throttle valve 4 and the muffler a11 in turn, the air pipe b12 on the b port side is connected to the air inlet of the workpiece seat 9, and the lower part of the solenoid valve 7 is provided with an air pipe c2. c2 is connected to cylinder 6.

[0013] The electromagnetic lock 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com