Slewing bearing and manufacturing method and application thereof

A technology for slewing bearings and manufacturing methods, which is applied to ball bearings, manufacturing tools, roller bearings, etc., can solve the problems of large slewing bearings and cumbersome installation processes, and achieve strength and firmness, simple installation process, and convenient installation The effect of arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

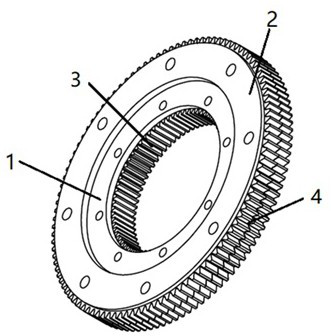

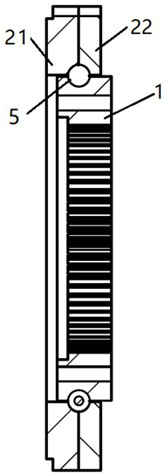

[0047] Example one, as image 3 As shown, when the rolling elements are balls 5, since the cross-section of the balls 5 is circular, correspondingly, the cross-sections of the annular grooves provided on the outer side of the inner ring gear 1 and the corresponding inner side of the outer ring gear 2 are both the same semicircle. In this way, when the inner ring gear 1 and the outer ring gear 2 are combined, the annular grooves of the two together form a circular raceway for accommodating the balls 5 .

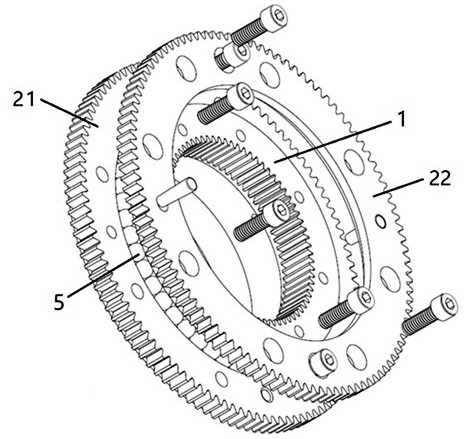

[0048] Further, when the outer ring gear 2 is composed of the first outer ring gear 21 and the second outer gear 22, when processing the annular groove, the first outer gear 21 and the second outer gear 22 are firstly fastened with fasteners Fasten them together, and make an annular groove with the joint seam of the two as the center line to ensure that the annular groove of the outer ring gear 2 and the annular groove of the inner gear 1 can accurately form the raceway of th...

Embodiment 2

[0049] Embodiment 2, when the rolling body is the roller 6, the section of the roller 6 is a square, and, as Figure 5 As shown, in the technical field, the adjacent rollers 6 are generally arranged in opposite directions, so as Figure 4 As shown in the figure, the cross-sections of the annular grooves provided on the outside of the inner ring gear 1 and the corresponding inner side of the outer ring gear 2 are the same isosceles right angle. The annular grooves together form a square roller 6 raceway.

[0050] Further, when the outer ring gear 2 is composed of the first outer ring gear 21 and the second outer gear 22, when processing the annular groove, the first outer gear 21 and the second outer gear 22 are firstly fastened with fasteners Fasten them together, and make an annular groove with the joint seam of the two as the center line to ensure that the annular groove of the outer ring gear 2 and the annular groove of the inner gear 1 can accurately form the raceway of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com