Combined rail transit wheel-mounted carbon-ceramic brake disc

A carbon-ceramic brake disc, rail transit technology, applied in the direction of brake disc, brake type, brake components, etc., can solve the problem of excessive temperature rise at the connection between the wheel and the shaft, affecting the interference fit between the wheel and the shaft, and production efficiency. Low problems such as saving operation and maintenance costs, improving production efficiency and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through examples. The features and advantages of the present invention will become more apparent from these descriptions. Obviously, the described embodiments are only some, but not all, embodiments of the present invention.

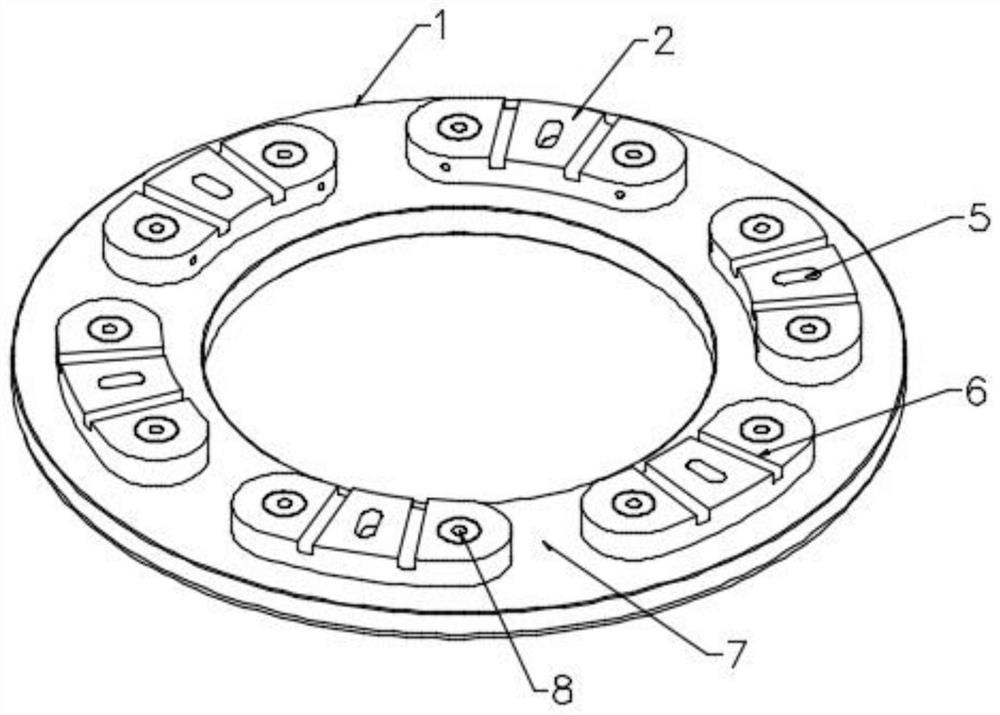

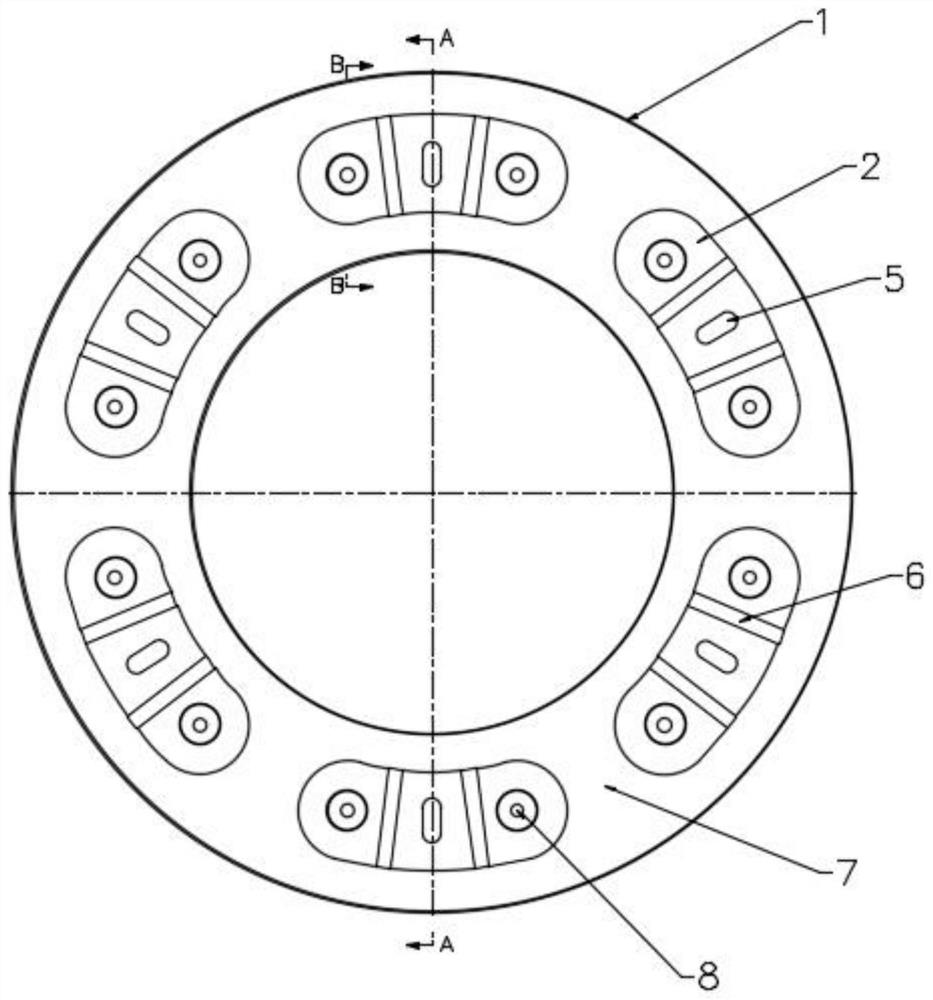

[0026] like Figure 1 to Figure 4 As shown, this embodiment provides a combined rail transit wheel-mounted carbon-ceramic brake disc, which includes a friction disc 1 and a plurality of support blocks 2 that are evenly arranged in the circumferential direction relative to the center of the friction disc 1. In this embodiment, 6 Block support block 2, the adjacent support blocks are arranged at an interval of 60° relative to the center of the friction disc; both ends of each support block 2 are assembled with the friction disc through inserts 3, and the inserts 3 axially pass through. Through the friction disc 1 and the support block 2, and through the set screw 4 to realize the axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com