Vacuum purification furnace of high-purity aluminum for preparing semiconductor chip

A semiconductor and vacuum technology, applied in the direction of furnaces, crucible furnaces, furnace types, etc., can solve the problems of long working hours of operators, single internal structure, and reduced practicability, so as to improve convenience and practicability, and the structural design is simple and reasonable , The effect of preventing vacuum leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

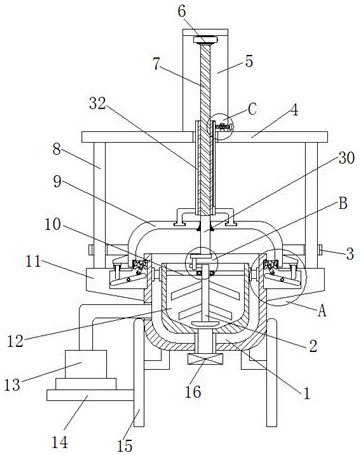

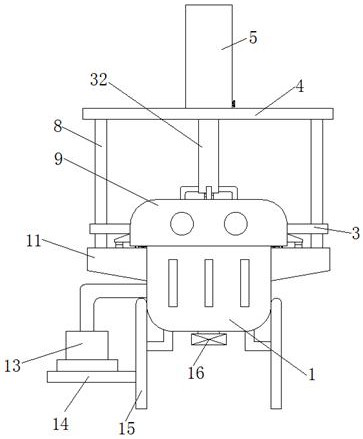

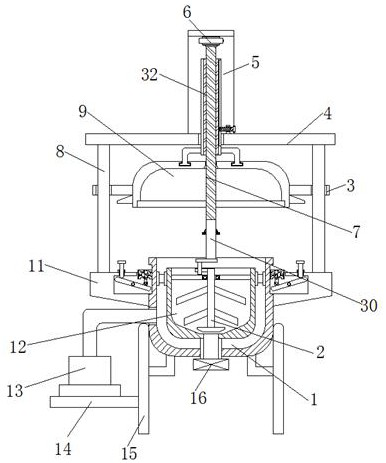

[0039] Example 1, as Figure 1-6 , 8 and 9, when working, the limit bolt 29 can be rotated first to make it rotate and move inside the inner threaded sleeve 28 and inserted into the limit chute 27, so as to realize the limit of the inner threaded sleeve 32 work, and then the rotating rod 30 and the thread 7 can be driven to rotate at the same time by the servo motor 6, so that the inner thread sleeve 32 rotates outside the thread 7, and at this time, the L-shaped sliding rod 33 is connected with the annular chute 31. When the inner threaded sleeve 32 moves upward, the sealing cover 9 can be moved upward to open the sealing cover of the vacuum purification furnace 1, so that the sealing cover 9 can drive the sleeve block 3 to slide upward on the outside of the limit rod 8. After the sealing cover 9 and the vacuum purification furnace 1 are completely opened, the material can be placed in the inner purification furnace 12, and then the servo motor 6 drives the rotating rod 30 an...

Embodiment 2

[0040] Example 2, as figure 1 , 3 As shown in 7, when the sealing cover 9 and the vacuum purification furnace 1 are in the cover work, the sealing cover 9 can drive the pressing block 19 to move down to press the resisting rod 18. The outside of the hinge plate 17 drives the hinge plate 17 to perform hinge rotation to stretch the coil spring 24, and the hinge rod 22 can be hinged and ejected through the hinge rotation of the hinge plate 17, so that the hinge rod 22 drives the sealing block 20. When the sealing cover 9 is moved up to release the cover of the vacuum purification furnace 1, the resistance to the resistance can be lifted. The rod 18 is pressed, and then the sealing block 20 and the resist rod 18 are driven by the elastic restoring force of the coil spring 24 to perform the restoration work, so as to realize the cover sealing work of the next operation. The sealing of the vacuum purification furnace 1 is realized during the integration process, which effectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com