Induction machine driving type electric control valve

An induction motor, driven technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of internal parts loss, no flow adjustment function, poor contact, etc., to achieve low noise, long service life, functional many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below by way of examples.

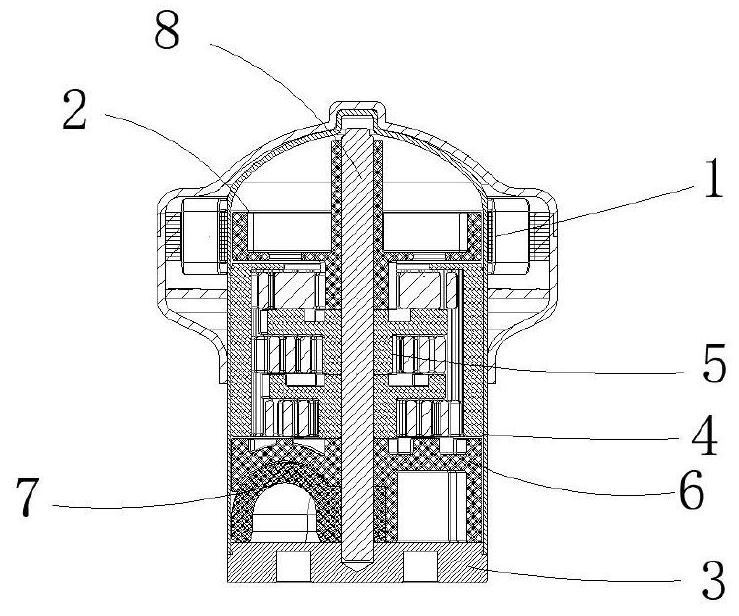

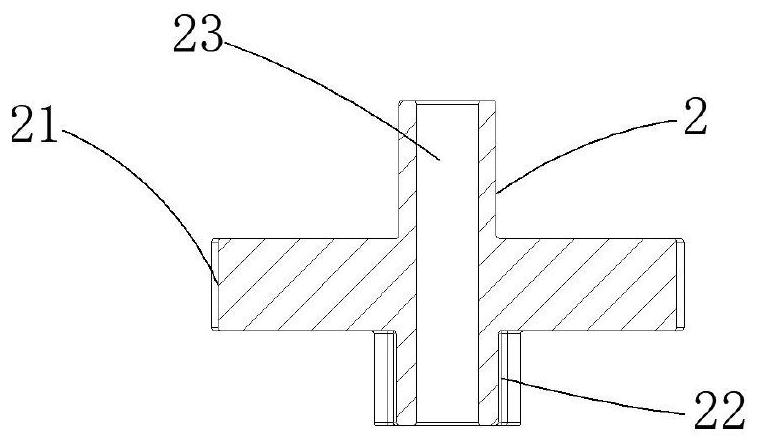

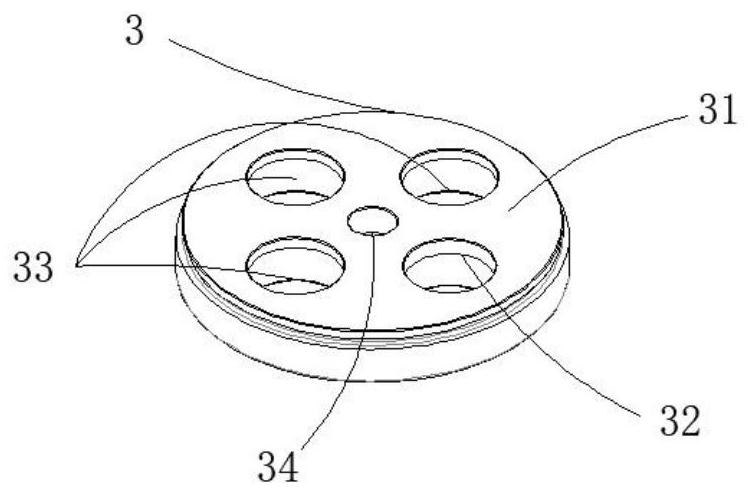

[0035] Combine figure 1 As shown, an induction motor drive type electrical control valve includes a valve body assembly, an induction motor, a reduction mechanism 5, a rotary valve disk device, an induction motor including stator 1 and a rotor 2, a sleeve fixed on a valve body assembly. 4 The outer wall of 4, the rotor 2 is mounted inside the sleeve 4;

[0036] When the induction motor is energized, the rotary magnetic field generated by the stator 1 interacts with the magnetic field generated by the rotor 2, so that the rotor 2 is rotationally moved; the rotor 2 drives the rotary valve disk apparatus by the reduction mechanism 5 as a rotational movement.

[0037] Here, the induction motor designated in the present invention is a stepping motor, or a brushless motor, which is controlled by the motor drive circuit board, and position control and location feedback can be ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com