Chemical equipment state monitoring and fault diagnosis method and system

A chemical equipment and fault diagnosis technology, which is applied in the field of chemical equipment status monitoring and fault diagnosis, can solve the problems of fault diagnosis and maintenance, status monitoring, chemical equipment not equipped with monitoring devices and fault diagnosis devices, etc., and achieve the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

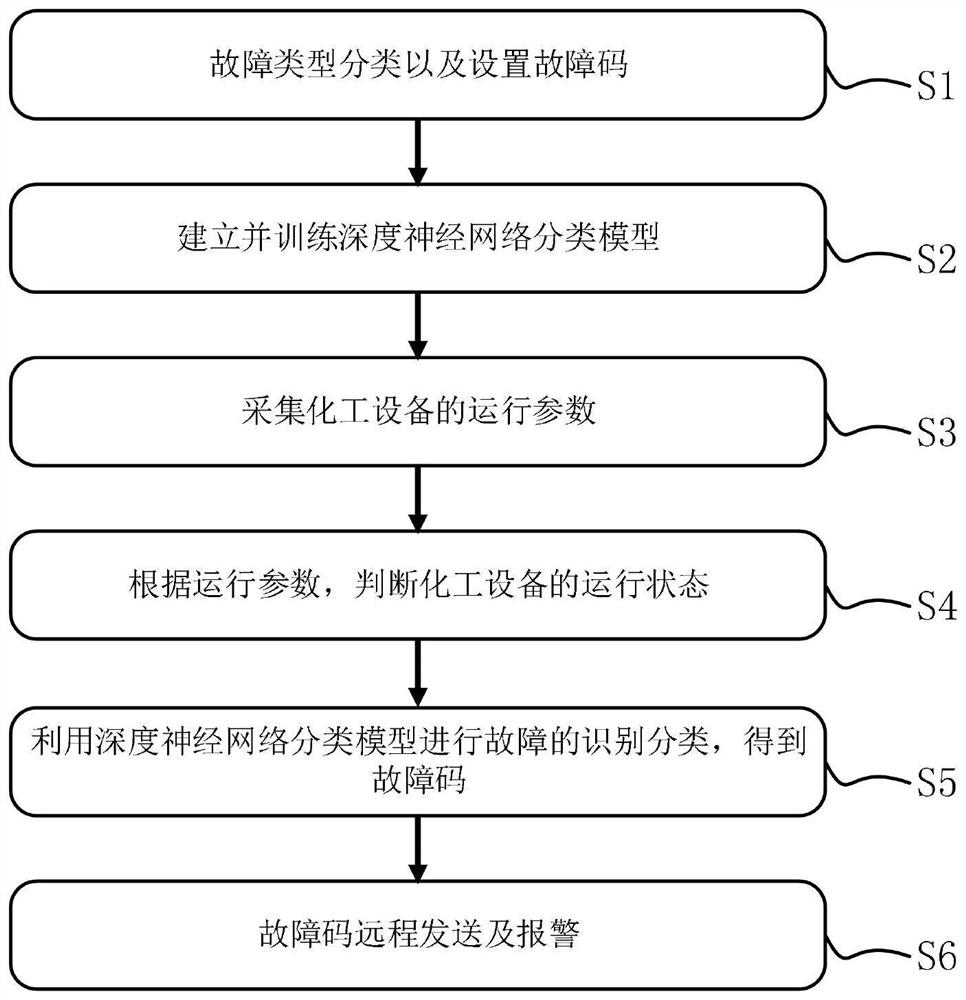

[0052] like figure 1 As shown, this embodiment proposes a method for state monitoring and fault diagnosis of chemical equipment, which includes the following steps:

[0053] Step S1, classifying fault types and setting fault codes. Specifically include:

[0054] Step S1.1, classify the fault types of the chemical equipment, and obtain multiple fault types.

[0055] The chemical equipment in the present invention is mainly aimed at chemical equipment with mechanical movement, such as fans, compressors, various pumps, etc., and these chemical equipment are equipped with motors, and the chemical equipment is driven by the motor for production and processing. The vibration and rotation of the motor in the equipment are monitored to determine whether it is faulty. Therefore, the fault types of chemical equipment mainly include several faults such as motor not rotating, abnormal motor speed (too slow or too fast), abnormal vibration of equipment, motor stuck, etc., and can also inc...

Embodiment 2

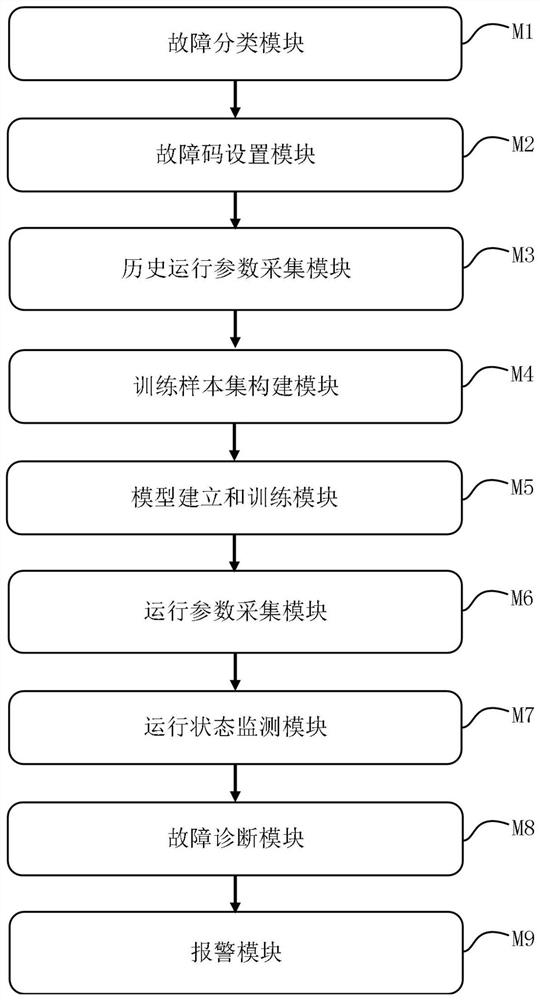

[0088] like figure 2 As shown, this embodiment provides a chemical equipment state monitoring and fault diagnosis system, the system adopts the chemical equipment state monitoring and fault diagnosis method in Embodiment 1, and the system specifically includes:

[0089] The fault classification module M1 is used to classify the fault types of chemical equipment and obtain various fault types;

[0090] The fault code setting module M2 is used to set a unique fault code for each fault type;

[0091] The historical operation parameter collection module M3 is used to collect the operation parameters of chemical equipment when various fault types occur, as historical operation parameters;

[0092] A training sample set construction module M4, configured to construct a training sample set according to the historical operating parameters, the fault types corresponding to each group of the historical operating parameters, and the fault codes corresponding to each fault type;

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com