Parametric design method for 3D printing protective mask

A parametric design and protective mask technology, applied in the field of 3D printing, can solve the problems of long protective mask cycle and incomplete protection, and achieve the effect of low cost, short processing time and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

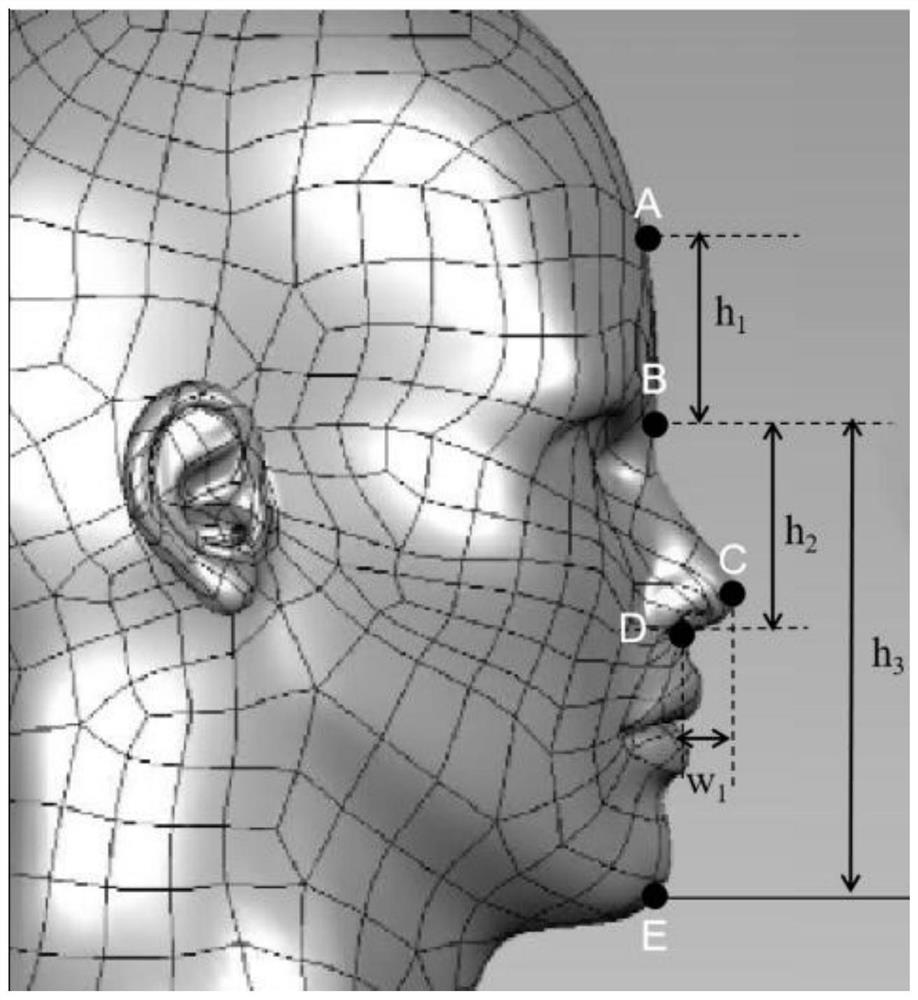

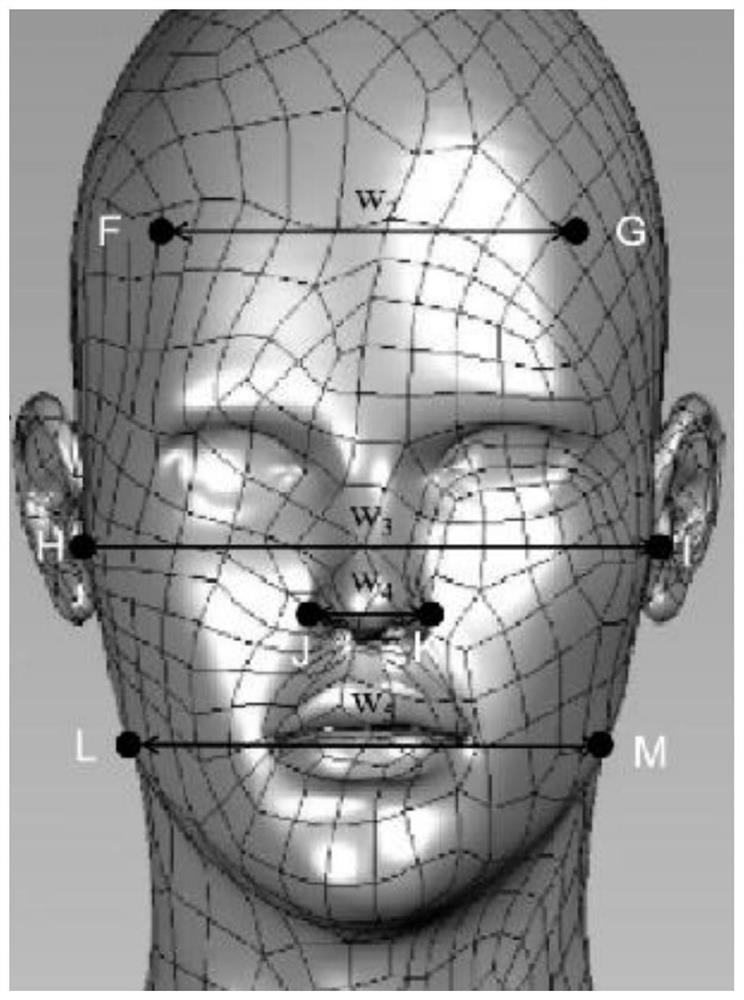

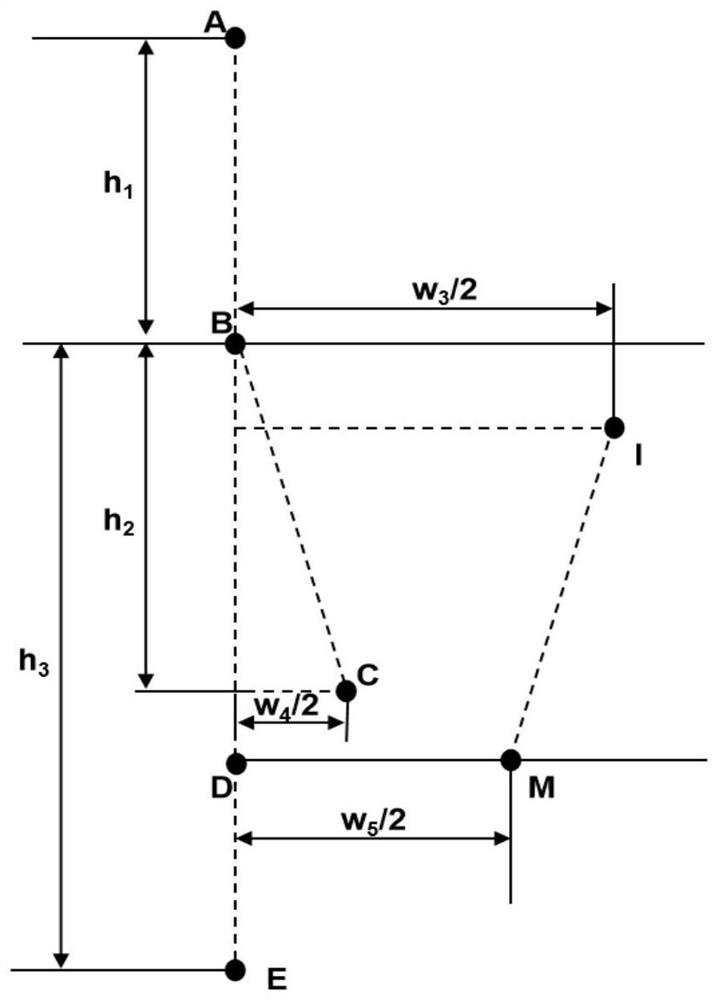

[0041] The parametric design method of the 3D printing protective mask of the present invention specifically includes the following steps: Step 1, the size classification and definition of key parts of the face (as shown in Figure 1, Figure 1 (a) is a facial feature diagram on the side of the human body; Figure 1 (b) ) is the frontal facial feature map of the human body): In Figure 1(a), A: frontal vertex, B: nasal root point, C: nasal tip point, D: subnasal point, E: submental point; in Figure 1(b) , F: left frontal vertex, G: right frontal vertex, H: left zygomatic point, I: right zygomatic point, J: left nasal alar point, K: right nasal alar point, L: left mandibular angle, M: right mandibular angle; Figure In 1(a), h1: frontal face length, h2: nose height, h3: morphological face length; w1: nose depth; in Figure 1(b), w2: minimum forehead w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com