Method for separating elastomeric particles

A technology of elastomers and granules, applied in applications, household appliances, and other household appliances, etc., can solve problems such as long disassembly and unusable time, long execution time, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

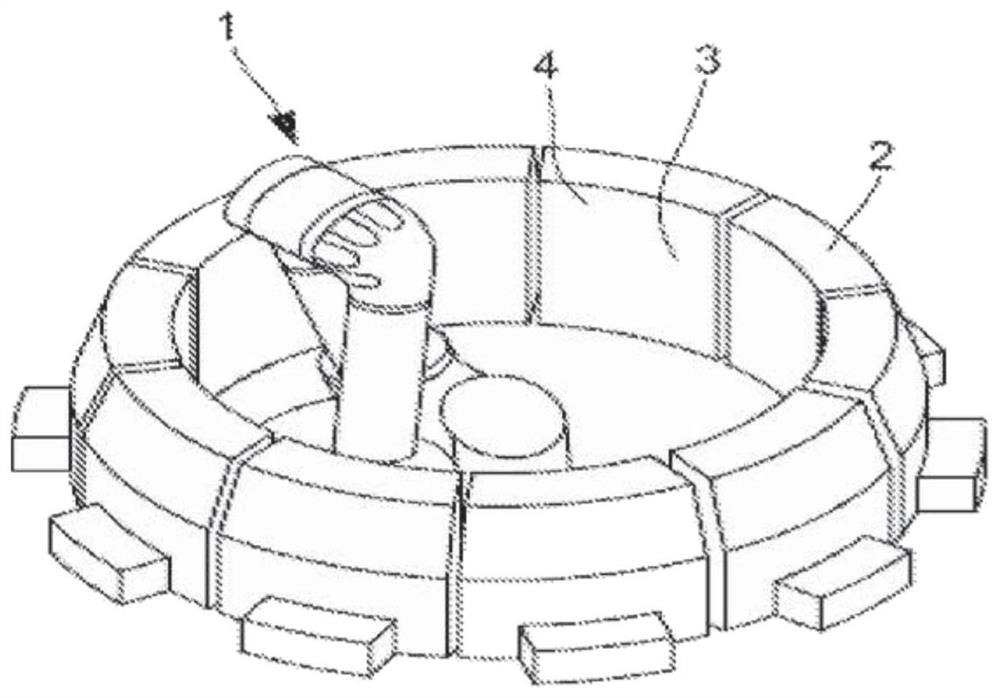

[0015] like figure 1 As shown, a cleaning device, designated generally by the reference numeral 1 , is provided in the tire curing mold 2 . The mould 2 includes a plurality of microvalves 3 arranged on the entire inner surface 4 thereof.

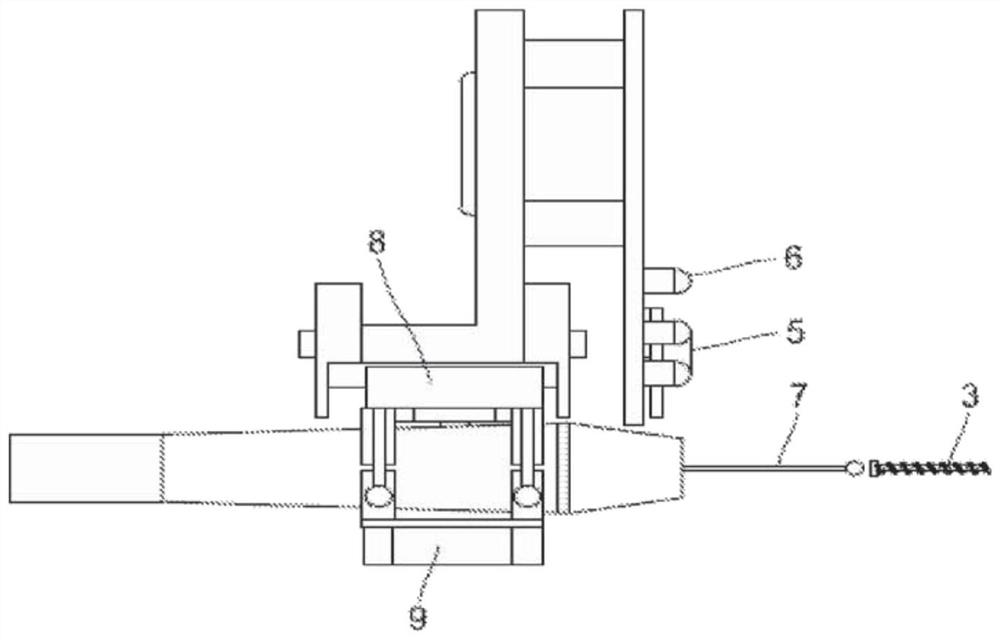

[0016] like figure 2 Shown in more detail, the device includes a camera 5 for detecting each microvalve 3 . The camera 5 is associated with an algorithm of the "Hough Circle Transform" type via a computer (not shown). The algorithm can perform a complete reading of the inner surface 4 of the mold 2 . The camera 5 is illuminated by a light source 6 of LED type. The device further comprises an ultrasonic pen 7 mounted on a track 8 for gradually bringing the pen into contact with the microvalve and an accelerometer 9 for detecting changes in frequency indicating the end of cleaning of the microvalve . Instead of an accelerometer, a microphone could be used, which would be used to record changes in vibration frequency by clicking.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com