Automatic seed separating device and seed separating method for plot sowing

An automatic and small-scale technology, applied to the parts of the planter, can solve the problems of large size of the seeding device and low degree of automation, and achieve the effects of low manufacturing cost, reduced labor intensity, and accurate sliding positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other without conflict, and the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

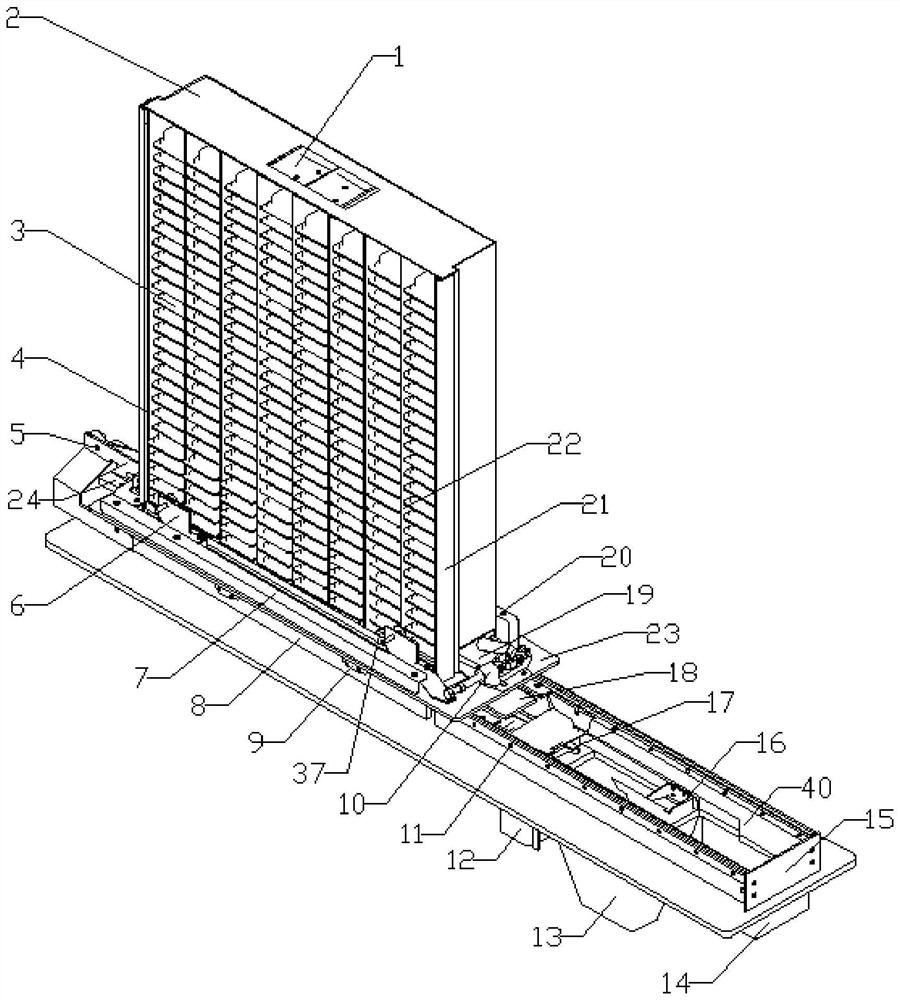

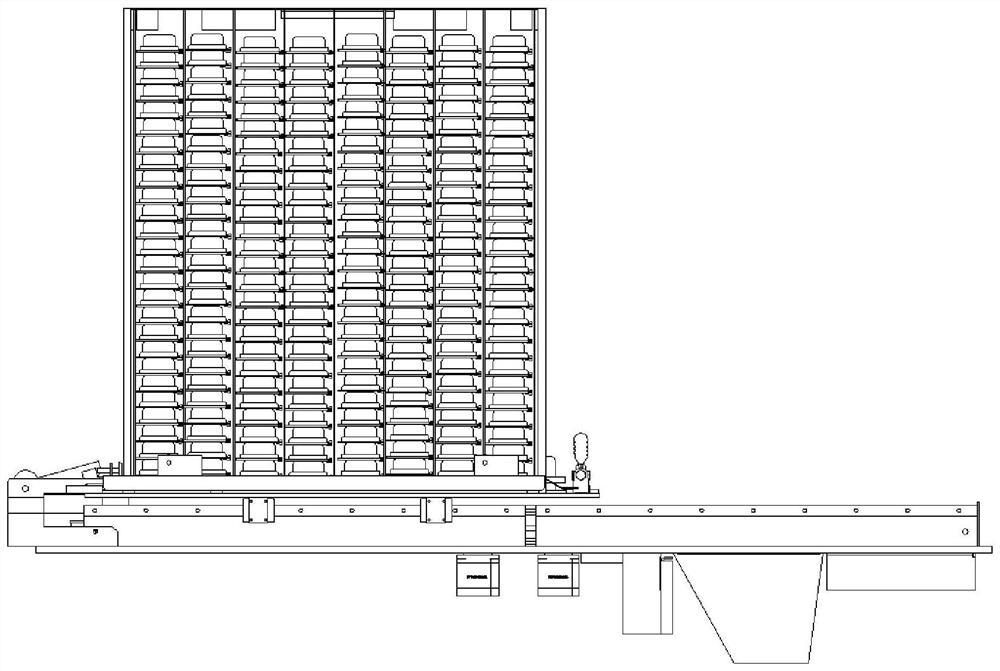

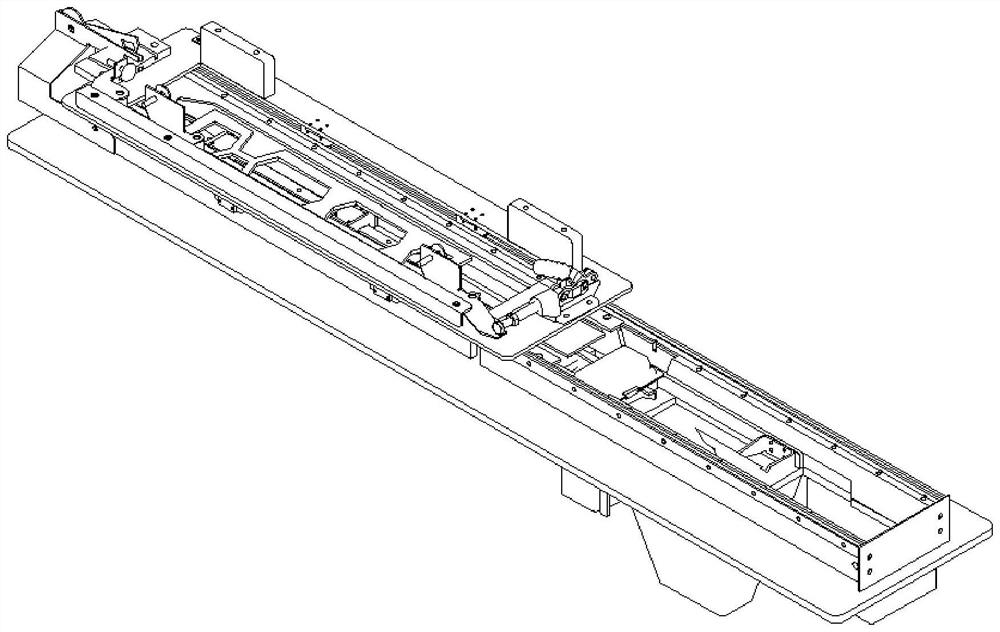

[0032] see Figure 1-6 Describe this embodiment, an automatic seed sorting device for cell sowing, which includes a seed box component, a seed box sliding table component, a push-out component, a fixed platform component and a drive component, and the seed box component includes a seed box box body 2 and a seed box. Insert plate 37, the seed box sliding table component includes the seed box sliding plate 23 and the clamping mechanism, the push-out component includes the push rod 33 and the orifice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com