Visual drainage tube

A technology of drainage tube and drainage bottle, which is applied in the field of medical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

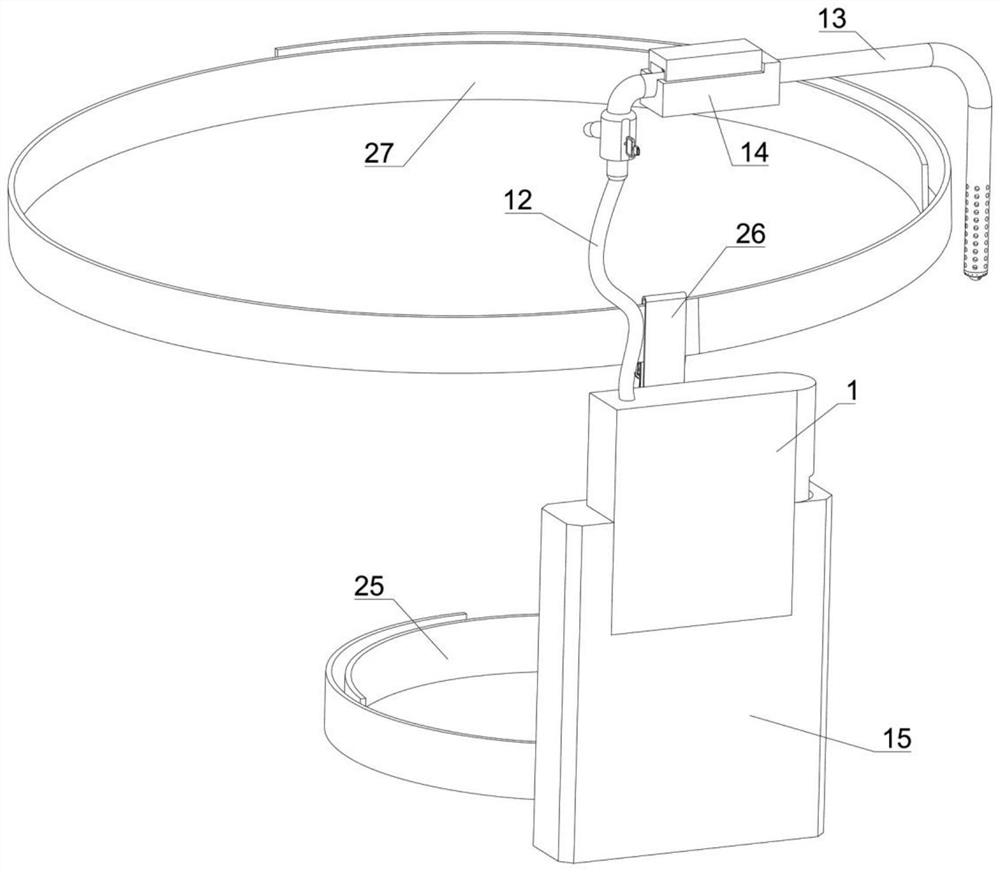

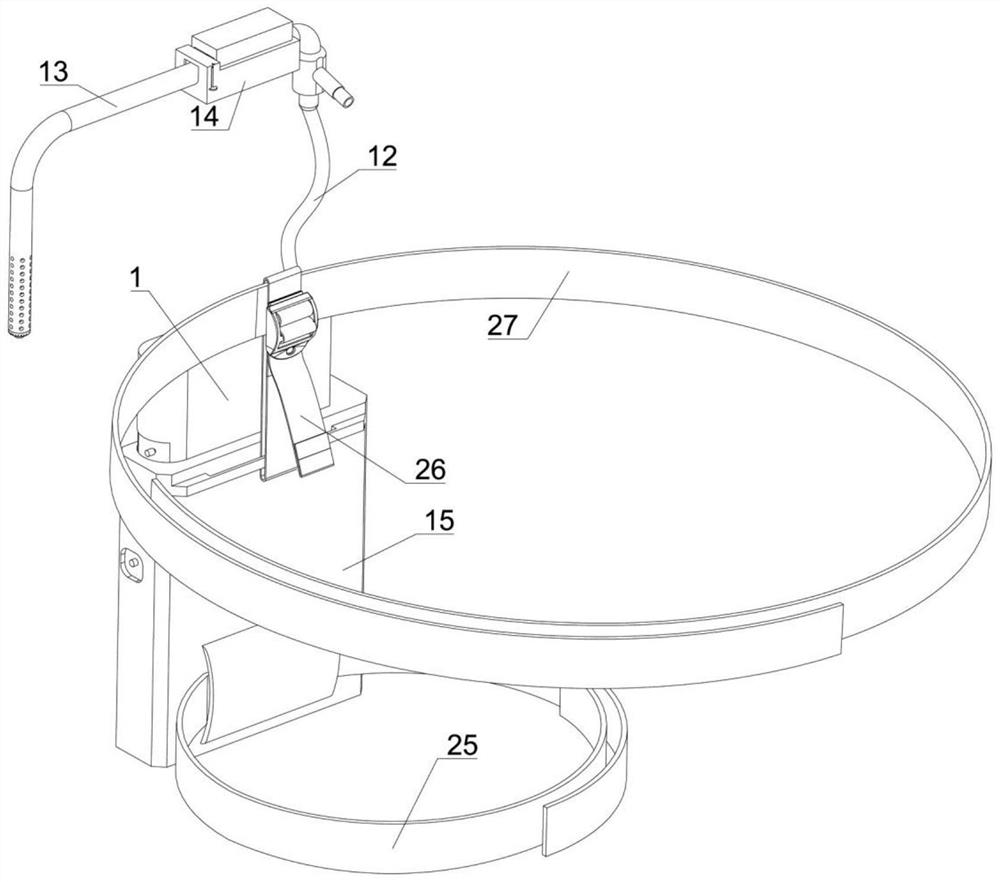

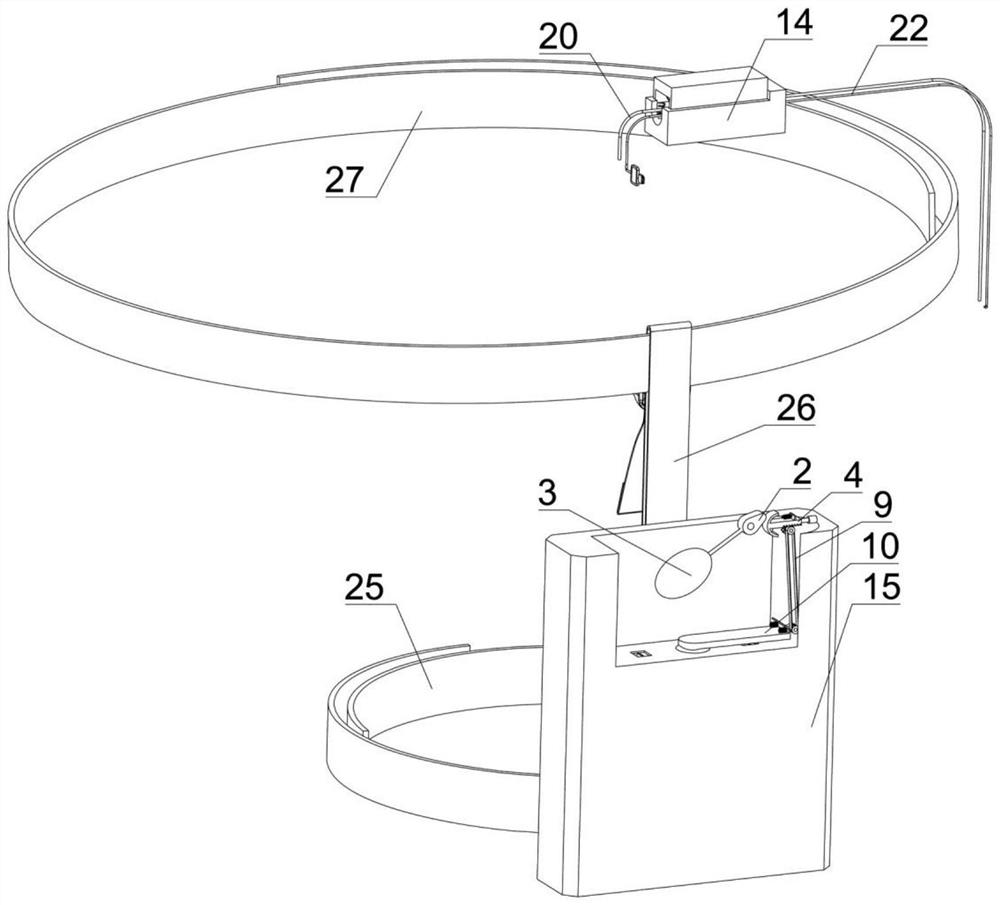

[0035] Example one, by Figure 1-Figure 6Given, in order to achieve the purpose of preventing liquid backflow, including a drainage bottle 1, a cam 2 is rotatably connected to the inside of the drainage bottle 1, a floating ball 3 is fixedly connected to the lower end of the cam 2, and the inside of the drainage bottle 1 A T rod 4 is slidably connected, the T rod 4 is T-shaped and one end of the T rod 4 is arc-shaped, the right end of the T rod 4 is fixedly connected with a first pressing rod 5, and the upper end of the T rod 4 is fixed A tension spring 6 is connected, the other end of the tension spring 6 is fixedly connected with the drainage bottle 1, and a toothed pulley 7 is rotatably connected to the inside of the drainage bottle 1. The toothed pulley 7 is composed of a gear and a pulley, so The toothed pulley 7 meshes with the T-bar 4, and the inside of the drainage bottle 1 is rotatably connected with a rotating wheel 8. The rotating wheel 8 is composed of a pulley and...

Embodiment 2

[0037] Embodiment 2, on the basis of Embodiment 1, by figure 1 , figure 2 , image 3 , Figure 7 , Figure 8 and Figure 9 Given, in order to achieve the purpose of preventing pipeline blockage, the pressing mechanism 14 includes a pressing box 1401 slidably connected with the second pipeline 13, and a pressing block 1402 is slidably connected inside the pressing box 1401. The pressing block The lower end of 1402 is fixedly connected with a plurality of moving springs 1403, the inside of the pressing block 1402 is fixedly connected with a plurality of pressing columns 1404, and the inside of the pressing box 1401 is slidably connected with a pressing block 1405. The pressing box 1401 A limit block 1406 is fixedly connected inside the limit block 1406, and a limit spring 1407 is fixedly connected to the left end of the limit block 1406;

[0038] When the liquid in the pipeline is thick and blocked, slide the pressing box 1401 to the designated position, and then slide the...

Embodiment 3

[0039] Embodiment 3, on the basis of Embodiment 1, by Figure 10 and Figure 11 Given, in order to achieve the purpose of fixing the drainage bottle, the fixing mechanism 16 includes a push plate 1601 slidably connected with the waste liquid bottle 15, and the upper end of the push plate 1601 is fixedly connected with two first barbs 1602, so A return spring 1603 is fixedly connected to the left end of the push plate 1601, a second pressing rod 1604 is fixedly connected to the right end of the push plate 1601, and two second barbs 1605 are fixedly connected to the lower end of the drainage bottle 1. A barb 1602, a push plate 1601, a second pressing rod 1604, a return spring 1603 and the first barb 1602 cooperate with each other to form the limiting structure of the drainage bottle 1;

[0040] When the drainage bottle 1 needs to be fixed on the waste bottle 15 , insert the second barb 1605 on the drainage bottle 1 into the waste bottle 15 , and the second barb 1605 will touch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com