Turbofan engine plug dismounting method, dismounting tool and dismounting simulation device

A technology for a turbofan engine and a dismantling tool, which is used in the field of dismantling simulation devices and engine runner inspections, can solve problems such as difficulty in dismantling, inability to see external ducts, plugs, self-locking nuts or bushings, etc. The effect of small space occupation, convenient dismantling simulation operation, and simple dismantling method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but it should not be construed that the scope of the subject matter of the present invention is limited to the following embodiments. Various modifications, substitutions and alterations made by common technical knowledge and conventional means are included within the scope of the present invention.

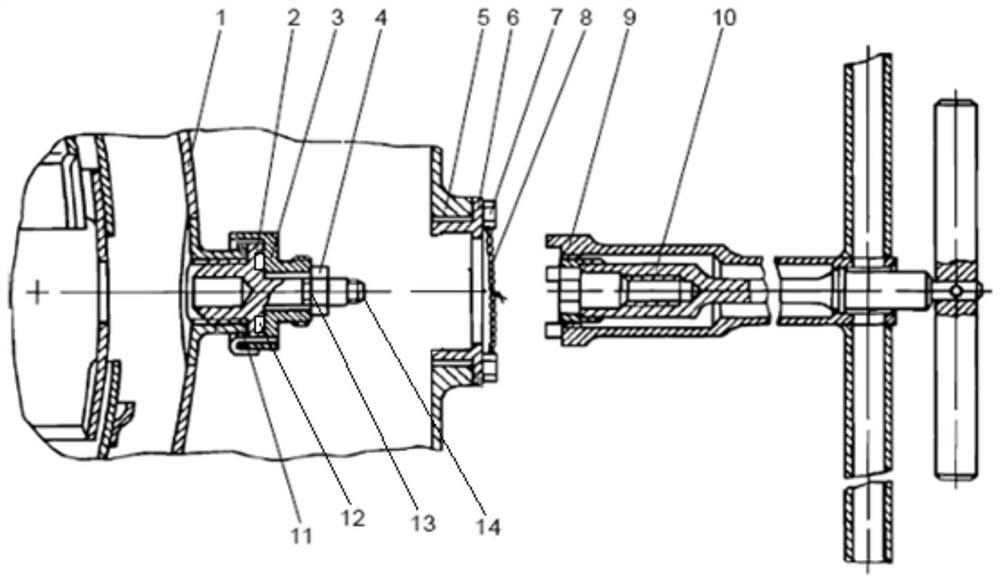

[0036] like image 3 As shown, the plug 2 is inserted into the inner hole of the boss mounting seat 11 of the combustion chamber casing 1, and a part of the structure of the plug 2 (the part connected with the self-locking nut 4 and the bushing 3) is located at In the outer duct of the turbofan engine between the combustion chamber casing 1 and the outer casing, the plug 2 is sleeved with a bushing 3, a gasket 13 and a self-locking nut 4, and the gasket 13 is located between the bushing 3 and the self-locking nut. 4, the outer surface of the bushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com