Translation docking mechanism in narrow space, material collecting device and working method of material collecting device

A docking mechanism and narrow space technology, applied in the direction of manipulators, manufacturing tools, etc., to achieve the effect of precise docking, high movement stability, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

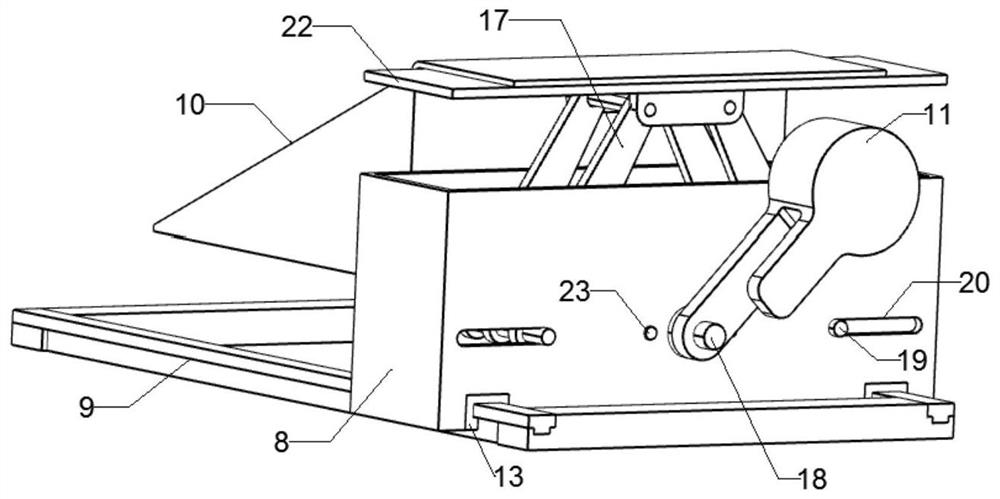

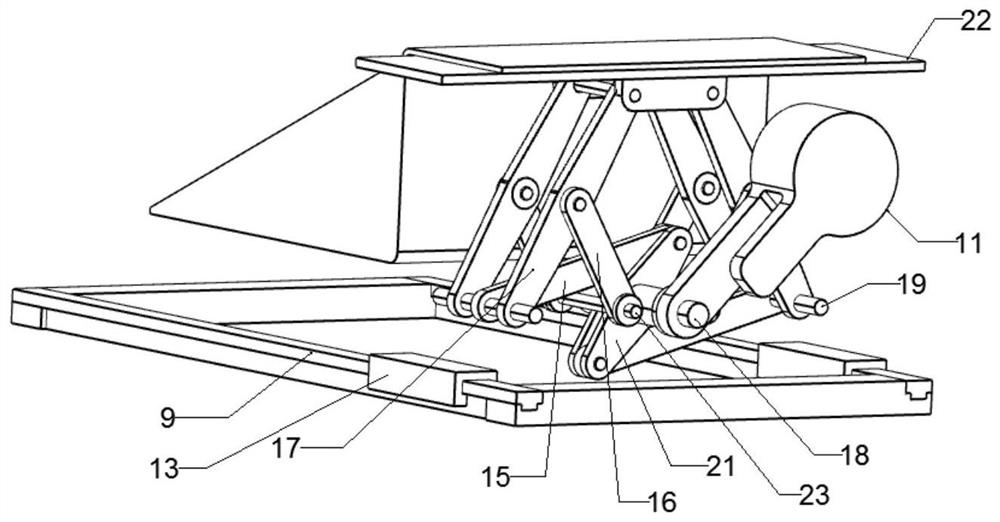

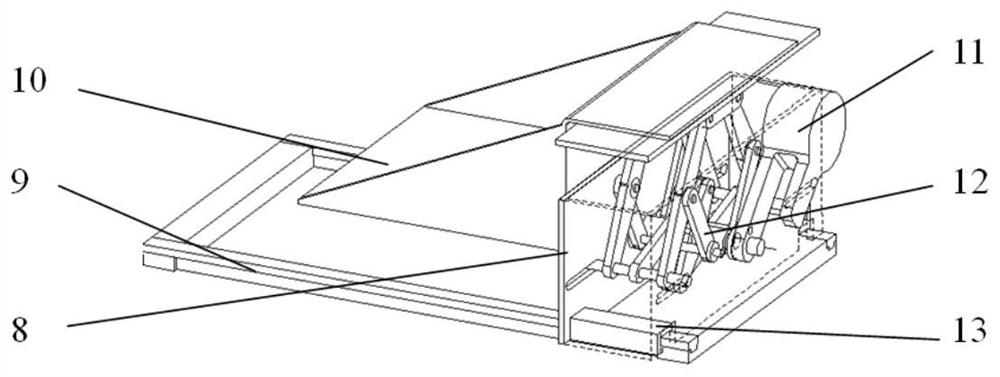

[0035] like Figure 1-Figure 3 , a translation docking mechanism with a manipulator operation function in a small space, including a translation part and a lifting part, the lifting part translates with the translation part, and the lifting part includes a box body 8, a lifting plate 22 and a connecting rod assembly 12;

[0036] The connecting rod assembly 12 includes a main shaft 18 and two translation shafts 19. The main shaft 18 is rotatably connected to the box body 8, and a counterweight 11 is fixed on the main shaft 18 to drive the main shaft 18 to rotate. The end of the translation shaft 19 is located in the elongated groove 20 of the box body 8 , the main shaft 18 is fixed with a driving rod 21 , and two ends of the driving rod 21 are respectively connected with a driven rod 15 in rotation. The other end of the driven rod 15 is rotatably connected with the corresponding translation shaft 19, and each of the translation shafts 19 is also rotatably connected with one or ...

Embodiment 2

[0043] like Figure 5-Figure 6 , a material collection device with a manipulator operation function in a narrow space, including a receiving tank 4, a collecting material tank 6 and the translation docking mechanism described in Embodiment 1, the bottom of the receiving tank 4 is provided with a docking port 3, and the collecting material tank 6. Under the action of the translation docking mechanism, it can be docked on the docking port 3 or separated from the docking port 3.

[0044]The tray 10 for placing the collecting material tank 6 is fixed on the lifting plate 22, and the lifting and lowering of the collecting material tank 6 is realized under the action of the connecting rod assembly 12, and under the action of the translation part, all the The translation of the collection tank 6 is described. When the lifting plate 22 descends, the collecting material tank 6 and the docking port 3 of the receiving tank are separated. Similarly, when the lifting plate 22 rises steadi...

Embodiment 3

[0051] The collection method of the material collection device as described in embodiment 2, comprises the following steps:

[0052] The material is spilled into the receiving tank 4, and the material can be collected into the collecting tank 6 through the funnel structure, and the counter-weight block can be moved counterclockwise by the manipulator. The connecting rod assembly can separate the collecting tank 6 from the docking port 3, and then Using the manipulator to push the tray 10 can move the collecting tank 6 out of the bottom of the receiving tank 4 as a whole, so as to facilitate the taking out of the collecting tank 6 . On the contrary, the new collecting material tank 6 can be pushed in and docked with the receiving tank 4, and the gripping port 5 can be operated by the manipulator, and the collecting device can be transferred to the process position where the material needs to be received, and the next material collection can be performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com