Tail device and method for TBM/shield rear matched continuous belt conveyor

A post-matching, continuous belt technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as low work efficiency and complex structure, and achieve the effect of improving work efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creation features, achievement goals and effects of the present invention easy to understand and understand, the present invention will be further described below with reference to the specific drawings.

[0031] Aiming at the technical problem of low work efficiency due to the complex structure of the existing tail device, based on this technical problem, the present invention provides a tail device for a continuous belt conveyor supporting a TBM / shield, which can realize non-stop The function of installing the extended fuselage frame assembly on the tail of the aircraft greatly improves the work efficiency and overcomes the problems existing in the prior art.

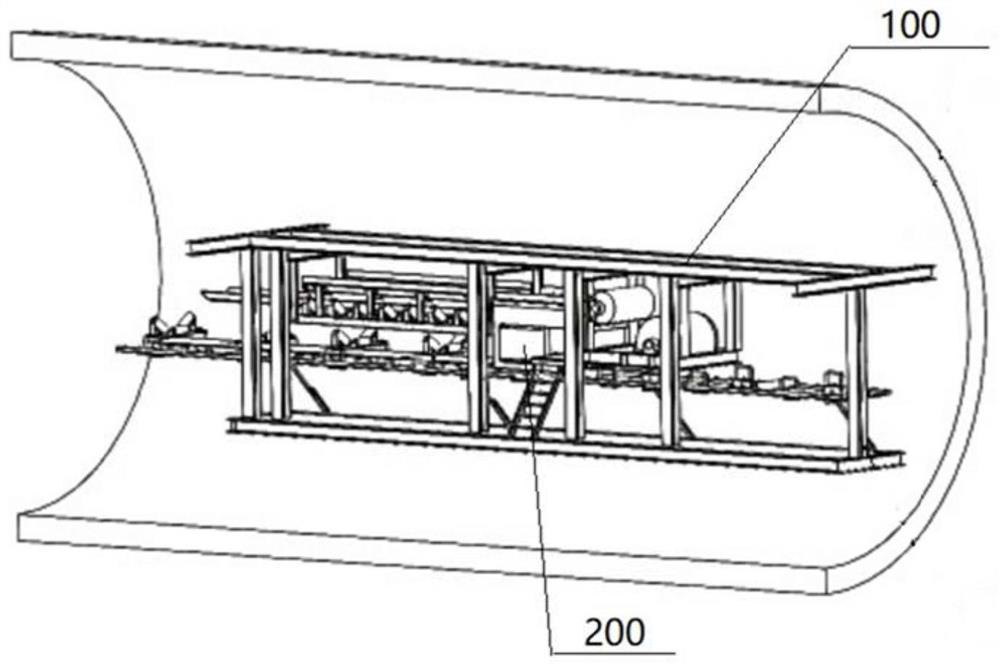

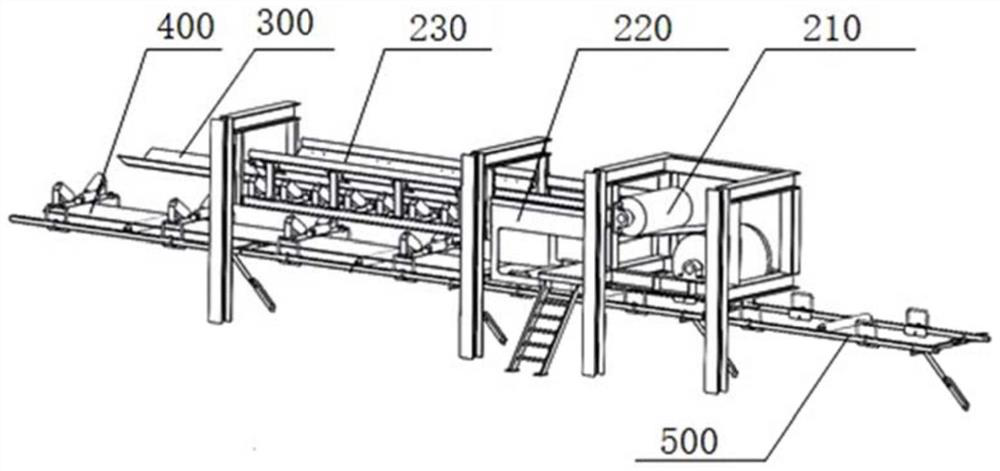

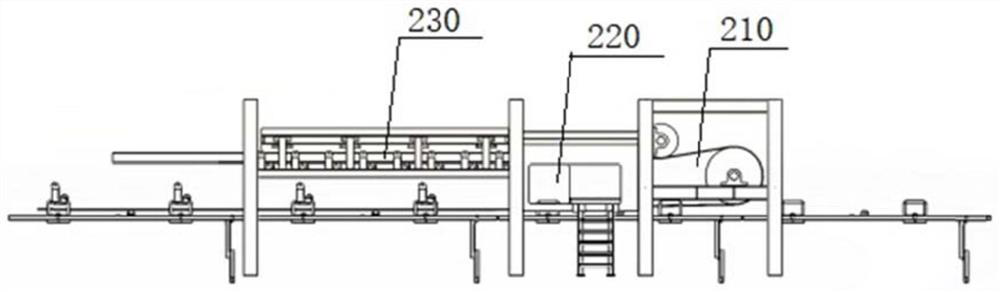

[0032] The tail device 200 for the continuous belt conveyor after the TBM / shield provided by the present invention, see Figure 1 to Figure 3 , which includes a tail redirecting device 210, an installation guard 220 and a material receiving device 230, a tail redirecting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com