Worm and gear speed reducer

A worm gear, reducer technology, applied in mechanical equipment, gear lubrication/cooling, belts/chains/gears, etc., can solve the problems of reducing the life of the reducer, reducing the service life of the reducer, affecting the running accuracy, etc., to reduce the power The use of the power source, the guarantee of normal operation, and the effect of improving the transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

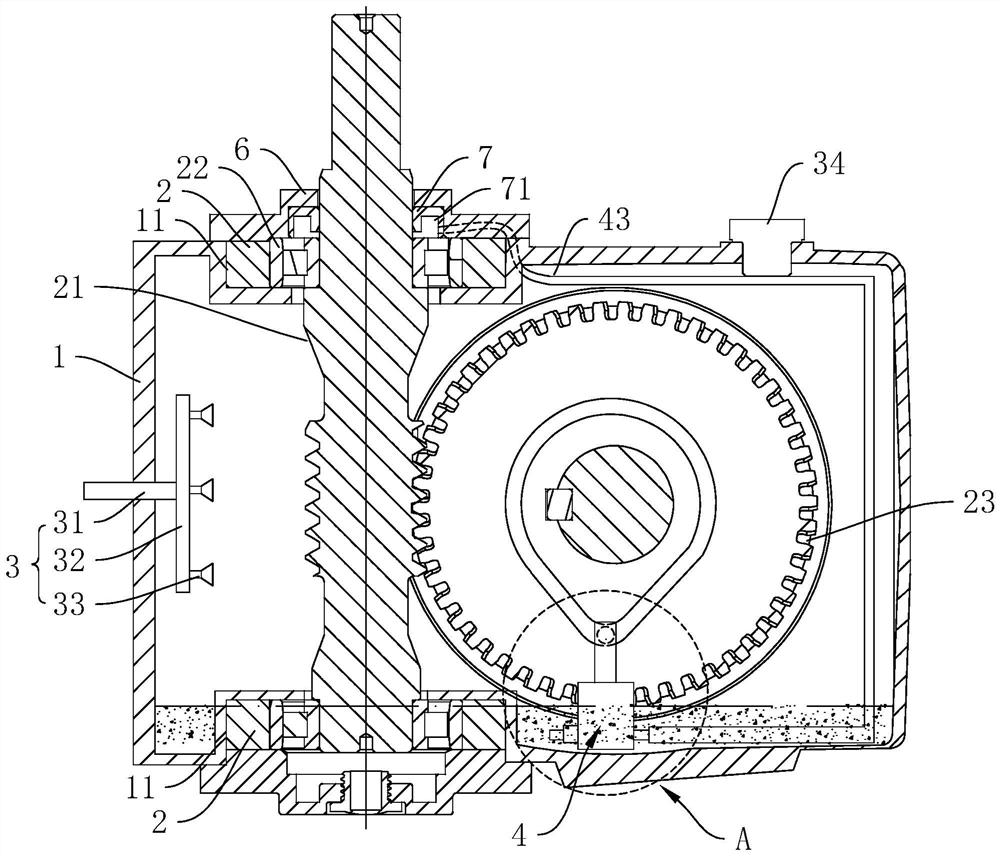

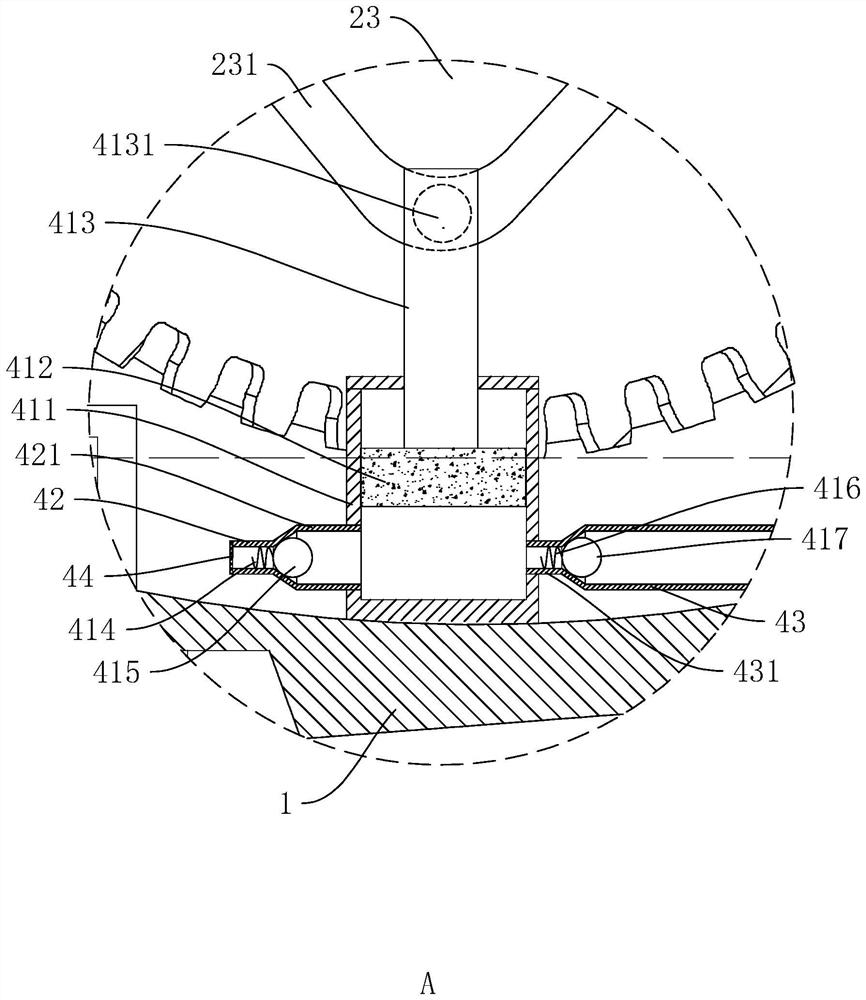

[0042] Attached to the following Figure 1-5 This application will be described in further detail.

[0043] The embodiment of the present application discloses a worm gear reducer. refer tofigure 1 , including a vertically installed box 1, the top and bottom of the box 1 are provided with mounting grooves 11, the bearing mounting seat 2 is installed in the mounting groove 11, and the bearing mounting seat 2 is provided with a worm 21, and the worm 21 and the bearing mounting seat A bearing 22 is connected between 2, and a worm wheel 23 meshing with the worm 21 is also arranged in the box body 1. The worm wheel 23 is rotatably connected with the side wall of the box body 1 through the output shaft. For the purging assembly 3, an oil supply device 4 for circulating oil is provided in the box 1.

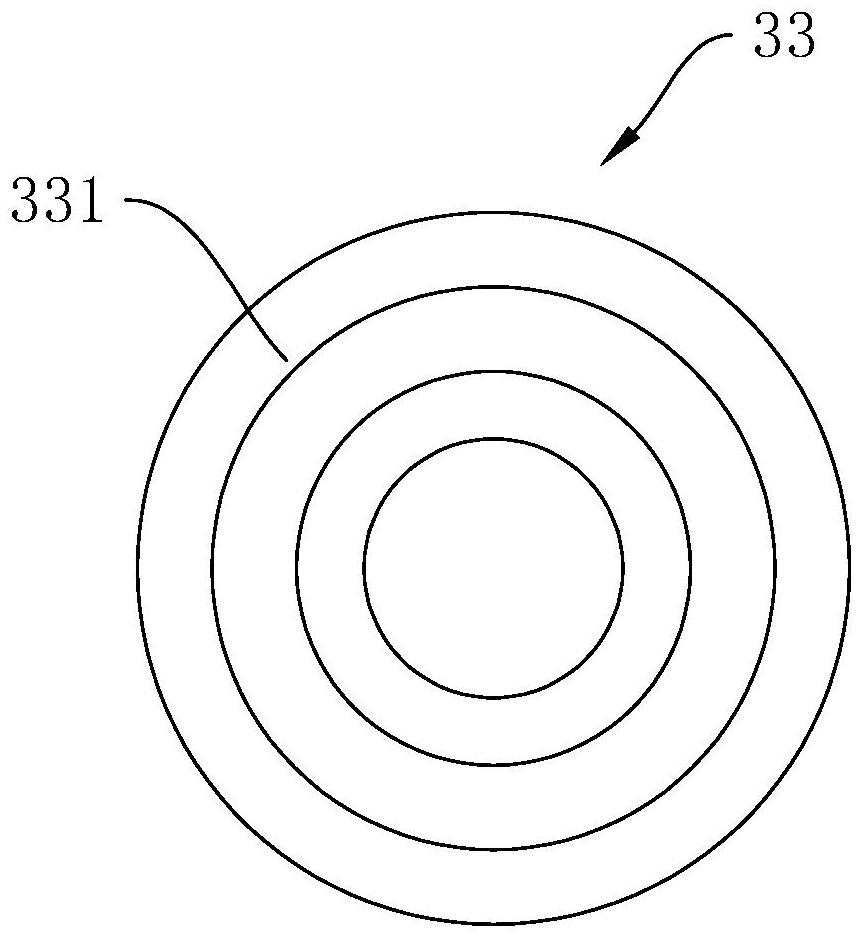

[0044] refer to figure 1 and figure 2 , the purging assembly 3 includes an air inlet main pipe 31, an air inlet branch pipe 32 and an air outlet 33. One end of the air inlet main p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com