Super high-rise concrete pouring quality control device

A control device, concrete technology, applied in the direction of measuring device, vibration suppression adjustment, spring/shock absorber, etc., can solve problems such as poor quality control of concrete pouring, and achieve the effect of improving the convenience of detection and reducing the intensity of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

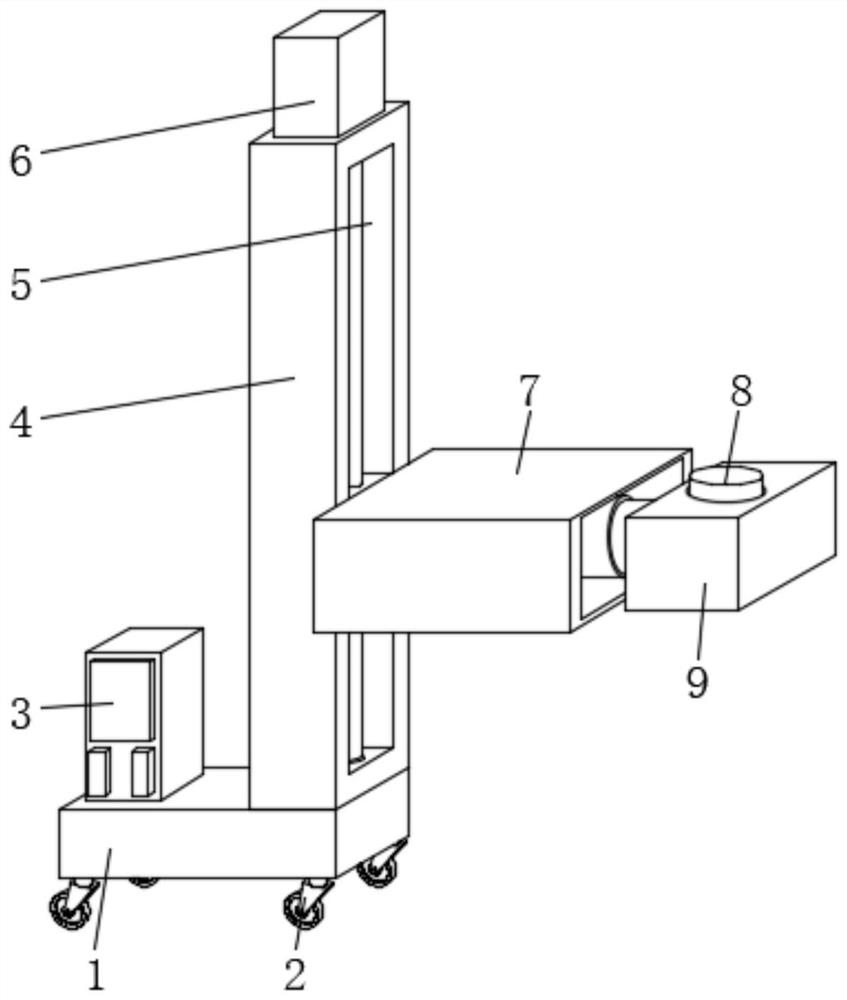

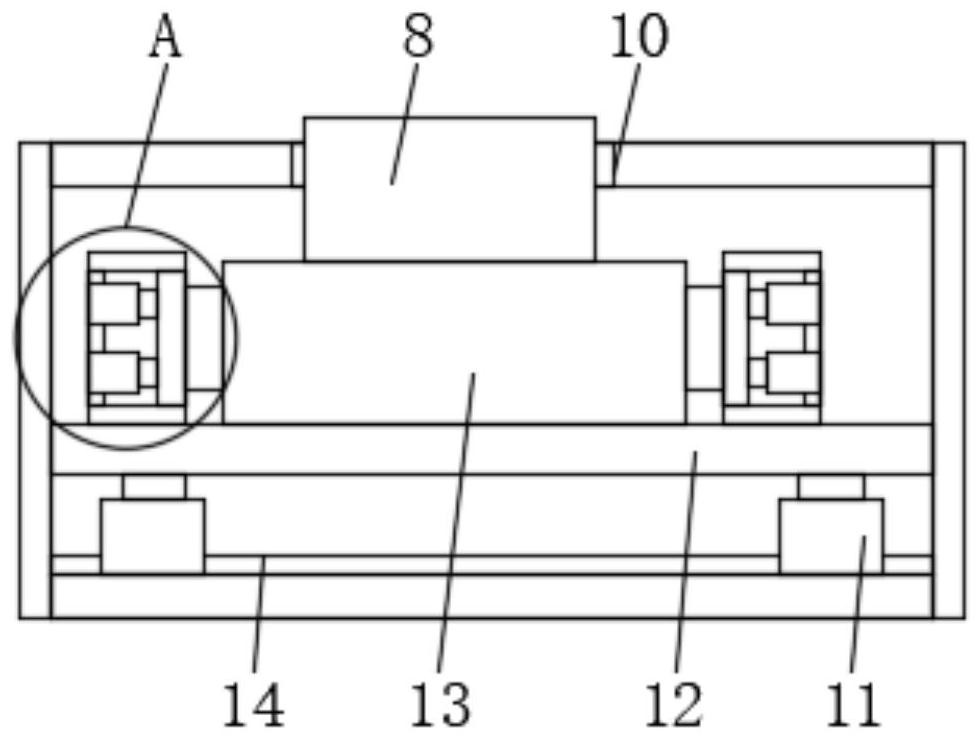

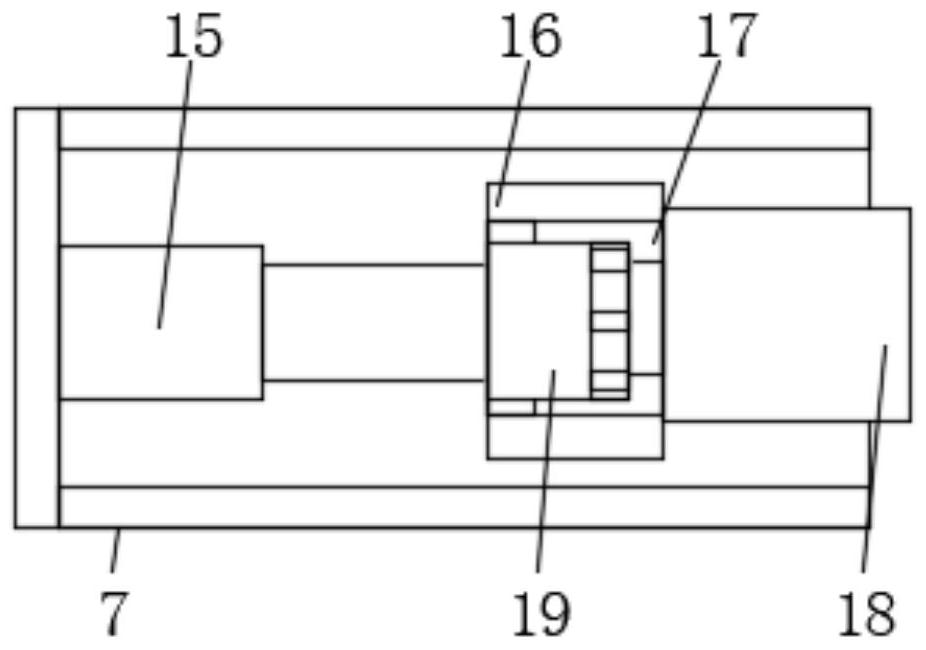

[0031] like Figure 1-6 As shown, the embodiment of the present invention provides a control device for the pouring quality of super high-rise concrete, including a base 1 and a protective groove frame 7, a control box 3 is provided on the left side of the upper end of the base 1, and a buffer groove 26 is provided at the lower end of the base 1, The inner upper end of the buffer groove 26 is provided with telescopic rods 23, the telescopic rods 23 are provided with a plurality of and are arranged at equal intervals, and the side of the telescopic rod 23 is provided with a mounting block 24, and the upper end of the mounting block 24 is connected with the inner upper end of the buffer groove 26, The lower end side of the telescopic rod 23 is provided with a spring 25, the lower end of the telescopic rod 23 is provided with a buffer block 27, and the lower end of the buffer block 27 is provided with a universal wheel 2, and the base 1 is conveniently moved and used through the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com