Biomass pellet fuel drying and forming device

A biomass particle and molding device technology, applied in the direction of promoting the preliminary treatment of solid material drying, drying solid material, non-progressive dryer, etc., can solve the problems of affecting the output efficiency, uneven rolling pressure, vibration, etc. To achieve the effect of improving extrusion efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

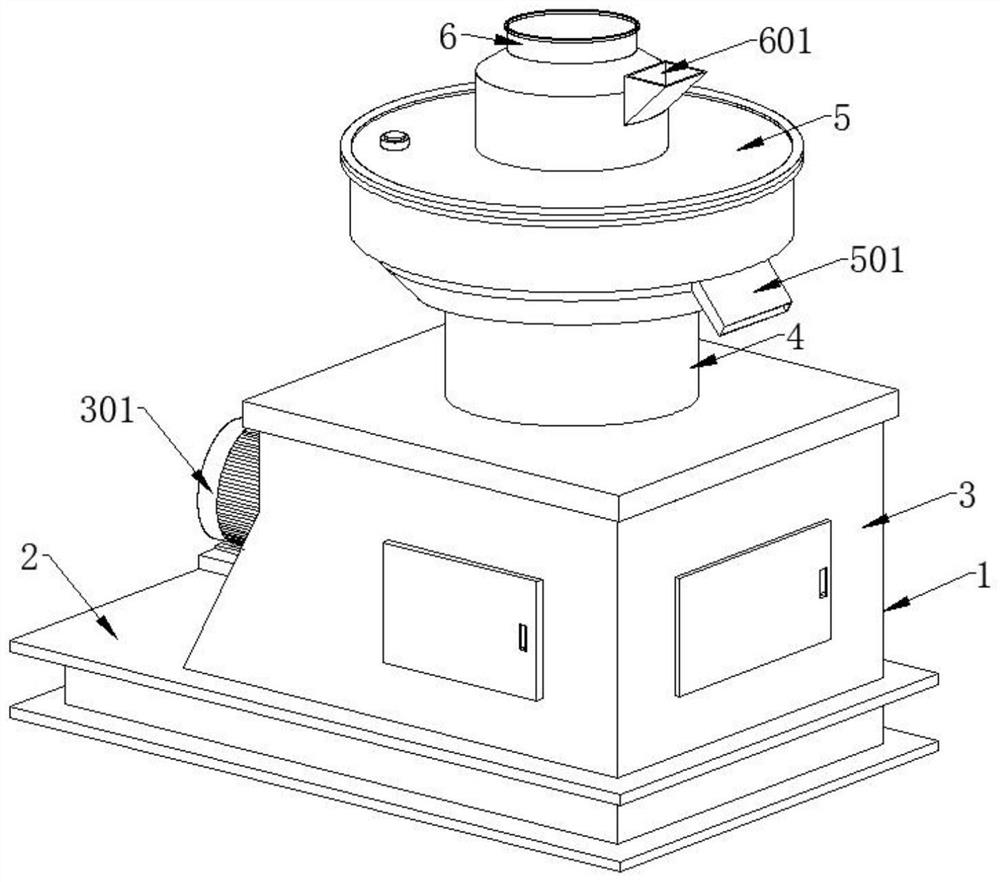

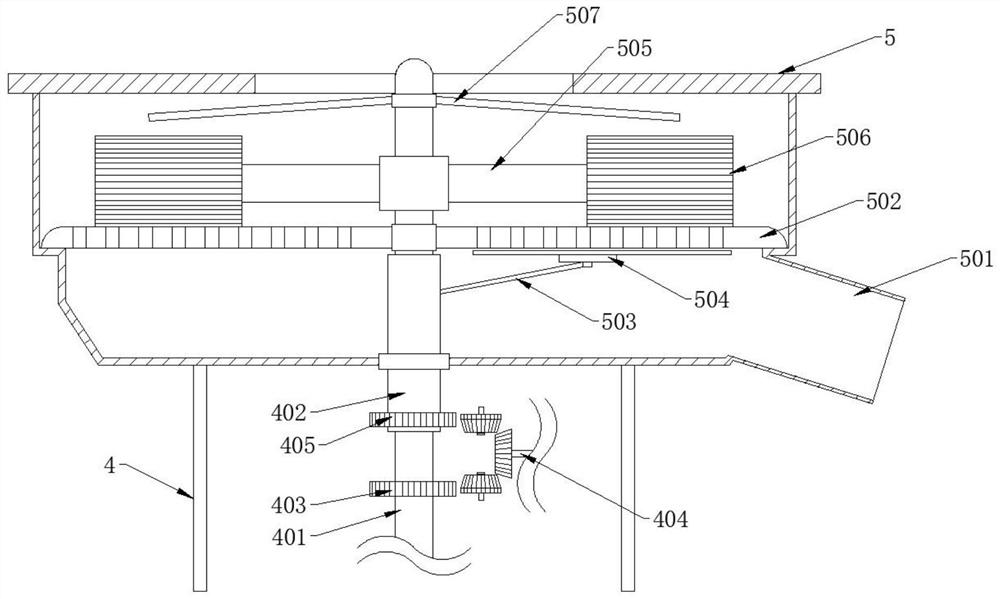

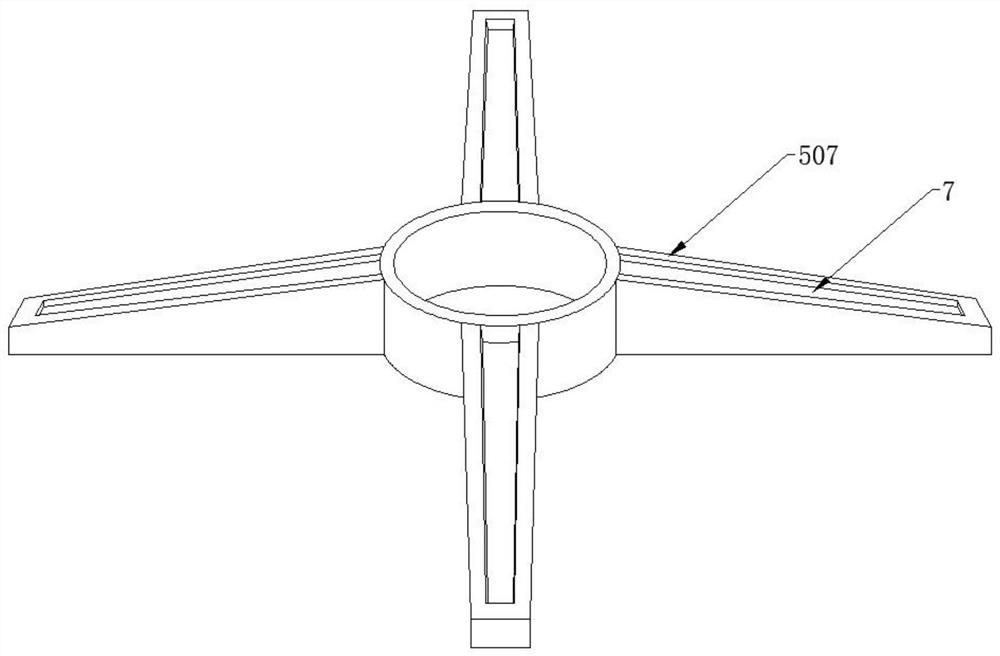

[0028] like Figure 1-5 As shown, the present invention provides a biomass pellet fuel drying and molding device, comprising a device main body 1, a base 2 is installed at the bottom end of the device main body 1, a driving base 3 is arranged at the top of the base 2, and one side surface of the driving base 3 is arranged There is a drive motor 301, a transmission column 4 is installed at the top of the drive base 3, and a rolling disc 5 is installed at the top of the transmission column 4, wherein a discharge port 501 is provided on one side of the bottom end surface of the rolling disc 5, and the rolling disc 5 A storage tank 6 is installed in the middle of the top end of the storage tank 6, and a feeding port 601 is provided on one side surface of the storage tank 6;

[0029] An inner shaft 401 is installed inside the transmission column 4, and the inner shaft 401 and the drive motor 301 are connected through the drive base 3 for transmission. One end of the first gear 403...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com