Fin heat exchange tube structure capable of efficiently transferring heat

A heat exchange tube and fin technology, which is applied in the field of finned heat exchange tube structure for efficient heat transfer, can solve the problems of adjustment and change of the finned heat exchange tube, limitations of the finned heat exchange tube, etc., and achieves good heat exchange efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The first embodiment of the present application is:

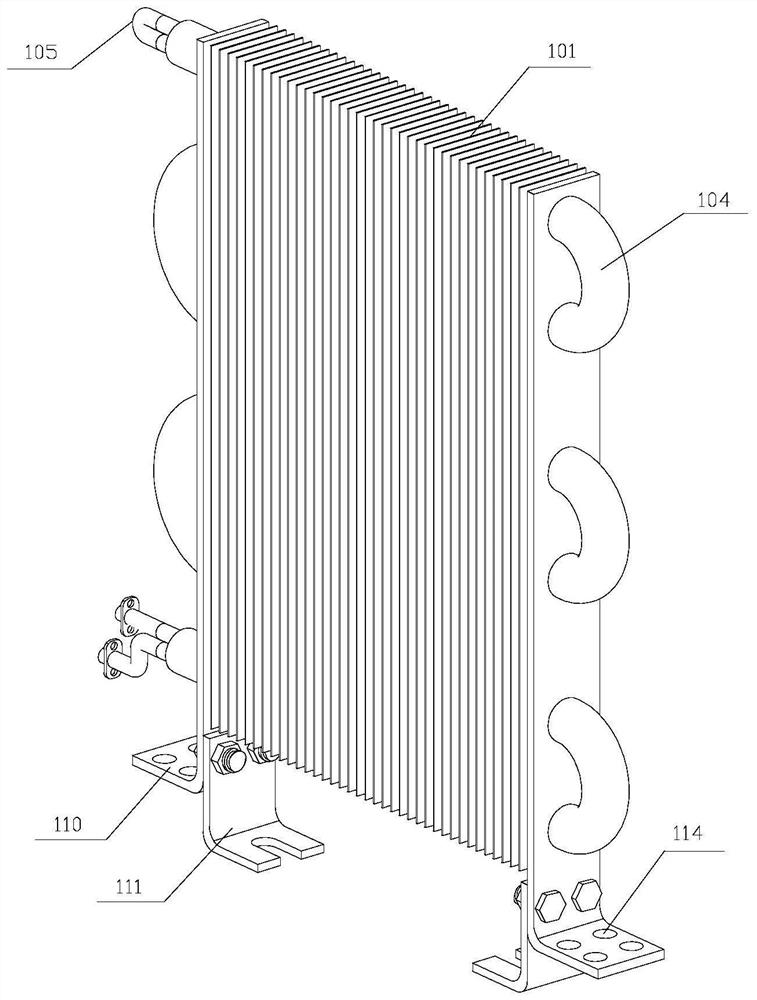

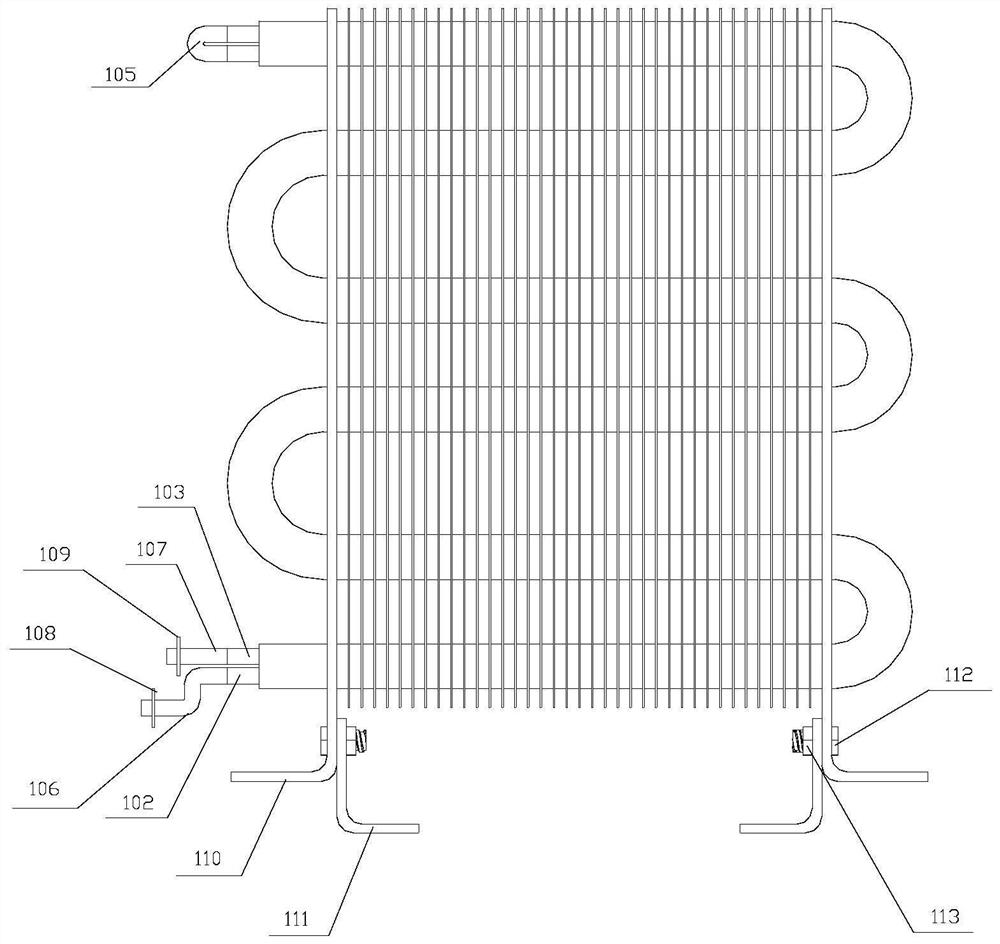

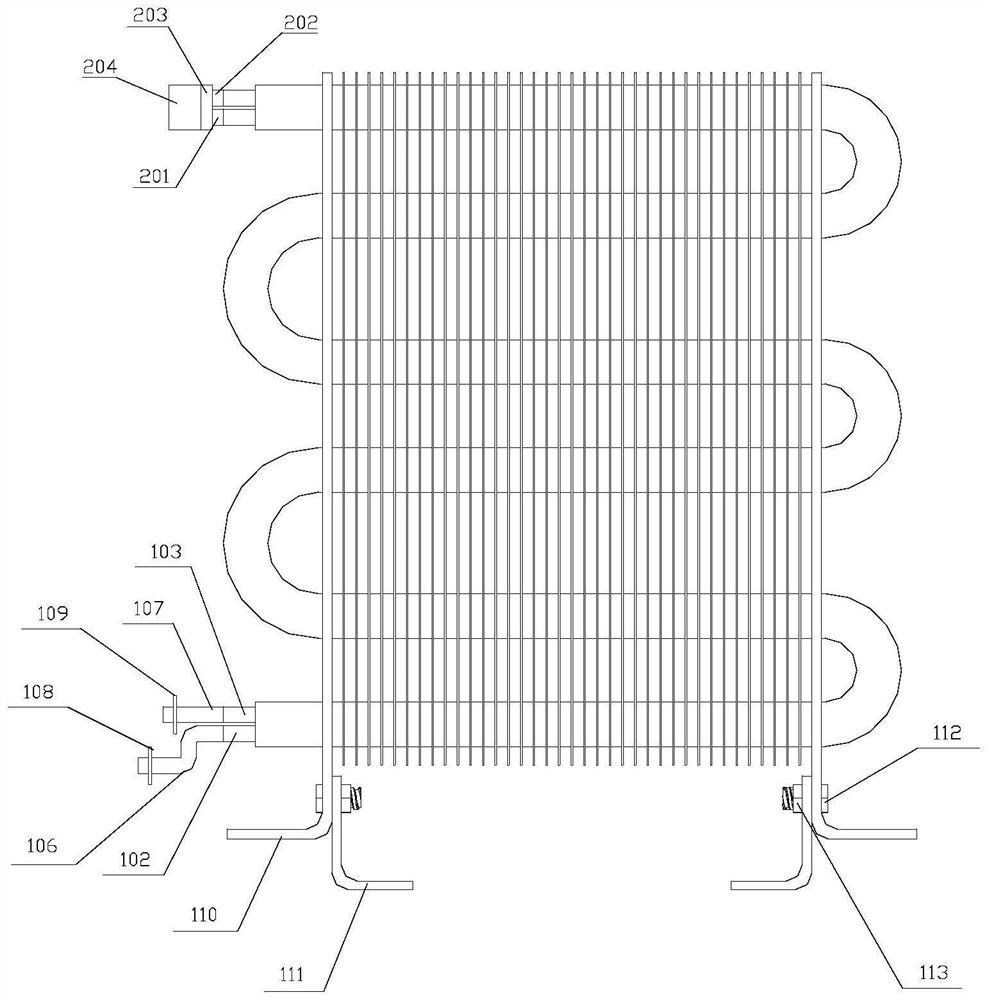

[0022] see figure 1 and figure 2 ,in figure 1 is a schematic structural diagram of the first embodiment, figure 2 It is a front view of the first embodiment, the present invention provides a finned heat exchange tube structure with high heat transfer efficiency: including fins 101 and a heat exchange tube mechanism, the heat exchange tube mechanism includes a first heat exchange tube 102, a second heat exchange tube The second heat exchange tube 103, the main body 104, the return elbow 105, the first inlet tube 106, the second inlet tube 107, the first interface ring 108, the second interface ring 109 and a mounting assembly including a mounting plate 110 , Install the clamping block 111 , the stud 112 and the nut 113 .

[0023] For this specific embodiment, the main body 104 is installed and fixed by the installation assembly, and the first heat exchange tube 102 is fed with fluid, and the fluid passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com