Micronl nano thermoacoustic vibration excitor based on thermoacoustic conversion

A thermoacoustic conversion and vibration exciter technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve problems such as the reasons are not difficult to understand, the thermoacoustic engine has no practical value, the research work has not been carried out, etc. Good acoustic oscillation characteristics, comprehensive functions and good heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further describe the present invention below in conjunction with accompanying drawing and specific embodiment:

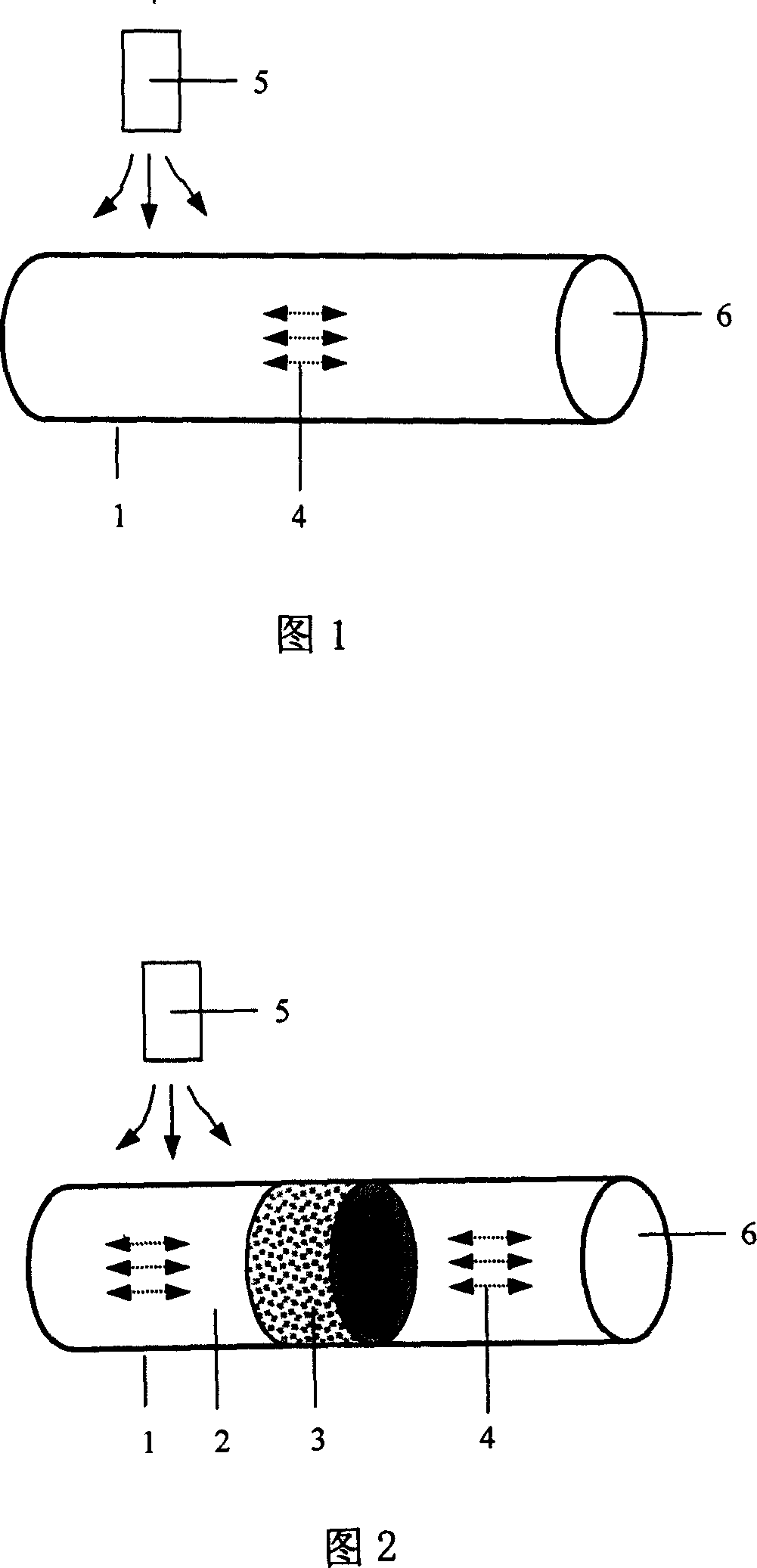

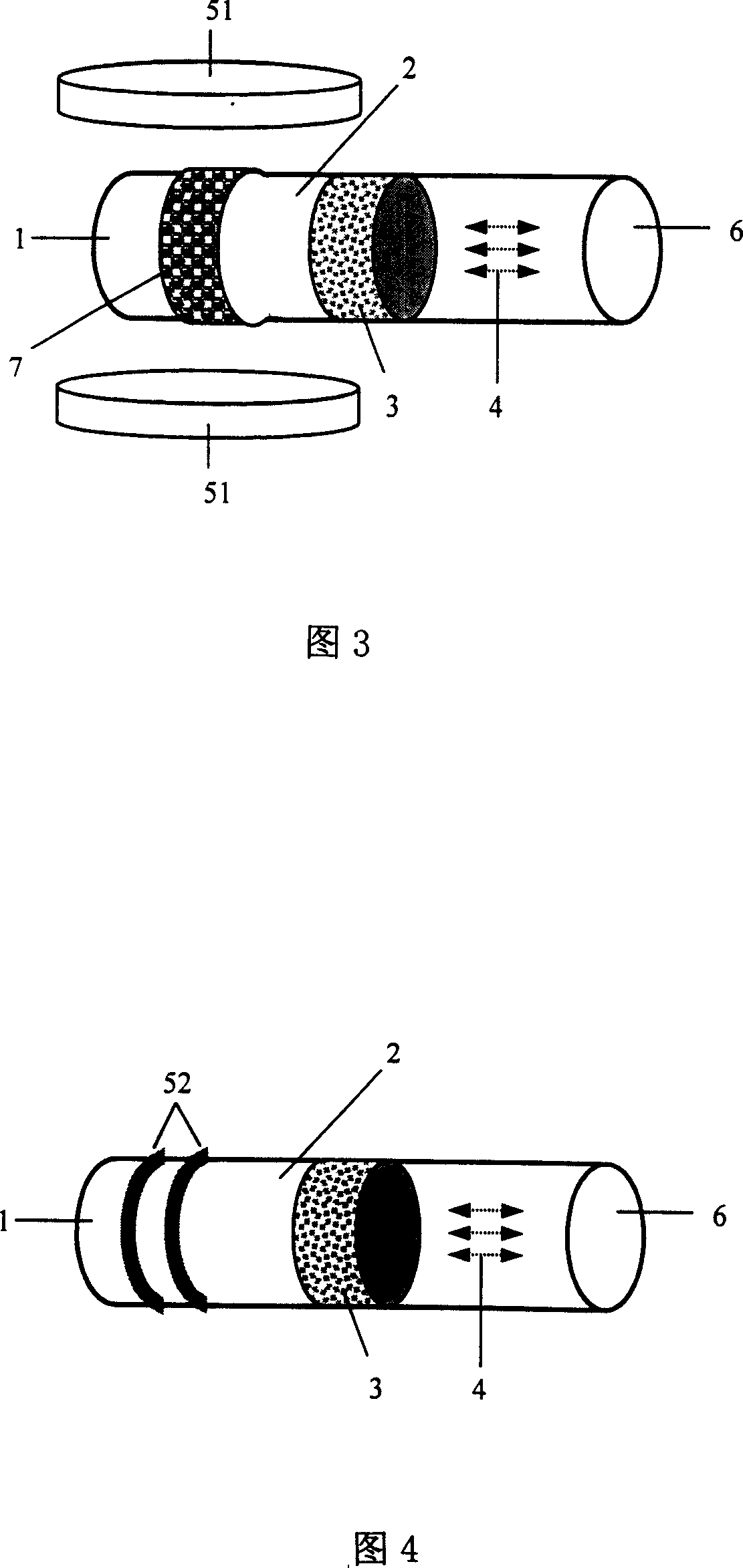

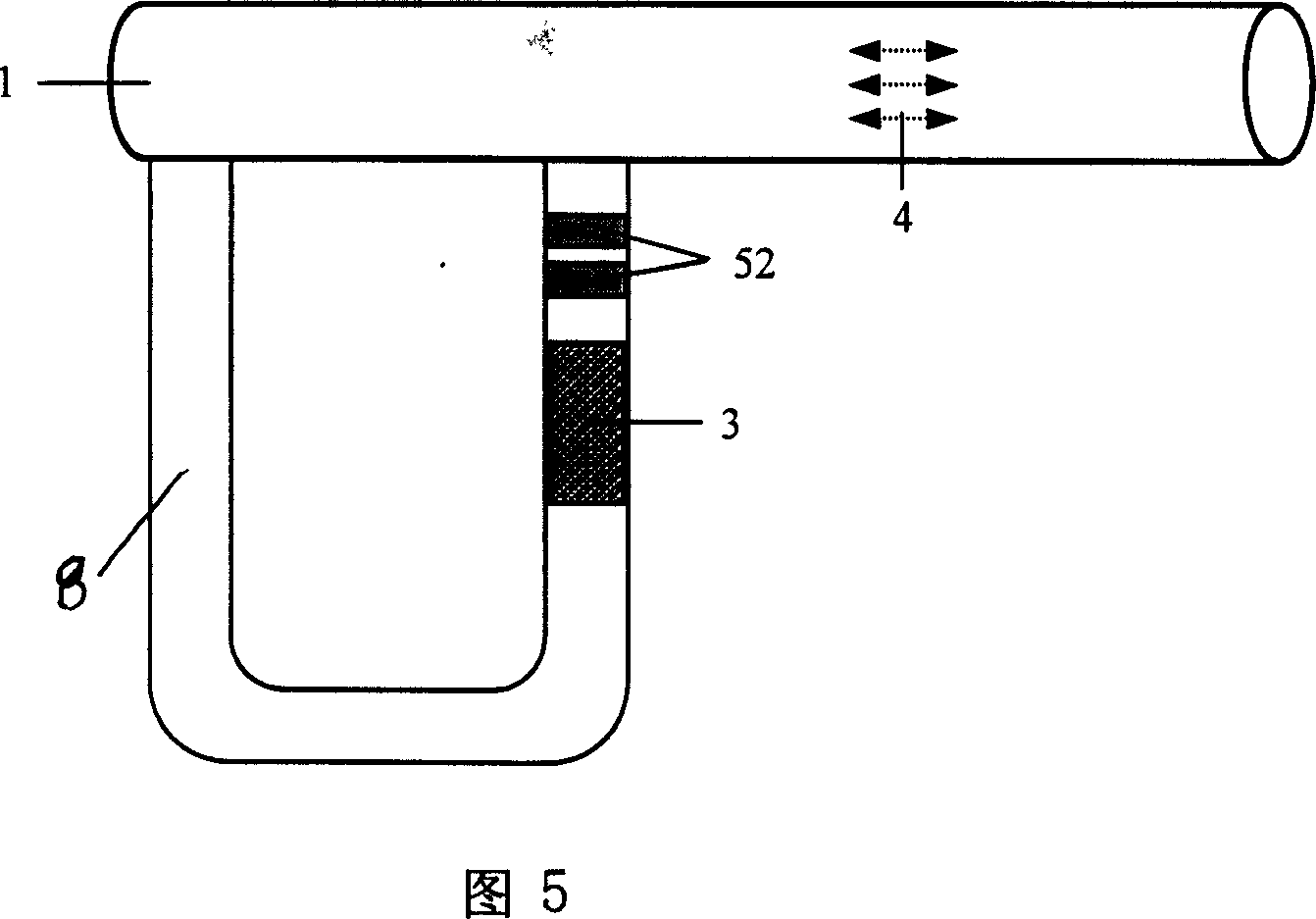

[0030] attached figure 1 It is a structural schematic diagram of the present invention (an embodiment); figure 2 It is a structural schematic diagram of the present invention (another embodiment); image 3 It is a structural schematic diagram of the present invention (another embodiment); Figure 4 It is a structural schematic diagram of the present invention (another embodiment); Figure 5 It is a structural schematic diagram of the present invention (an embodiment with a cyclic bypass to form a traveling-wave thermoacoustic exciter).

[0031] As can be seen from the figure, the micro / nano thermoacoustic exciter based on thermoacoustic conversion provided by the present invention includes:

[0032] A nanotube 1; one end of the nanotube 1 is closed, and the other end is equipped with a vibrating membrane 6, and the vibrating membrane 6 is an elastic memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com