Detection tool and turbocharger volute detection method

A technology of inspection fixtures and volutes, which is applied in the field of inspection of inspection fixtures and turbocharger volutes, can solve problems such as low detection efficiency, achieve the effect of simplifying inspection steps and improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

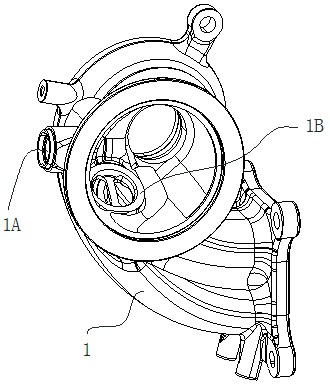

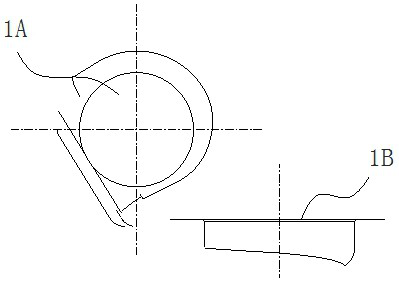

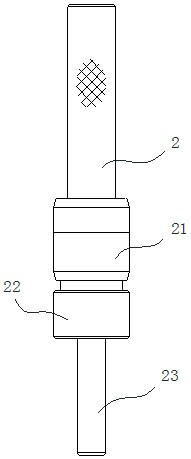

[0035] like Figure 1 to Figure 7 As shown, a checking tool includes a bushing reference shaft 2, including a centering shaft segment and a measuring shaft segment 23, the centering shaft segment is adapted to cooperate with the bushing hole 1A of the scroll casing 1, so as to make the centering The centerline of the shaft section coincides with the centerline of the bushing hole 1A, the centering shaft section coincides with the centerline of the measuring shaft section 23, and the outer diameter of the highest point on the measuring shaft section 23 is between the exhaust valve end face 1B. The distance between them is the distance to be measured; the dial indicator is suitable for matching with the outer diameter surface of the highest point of the measuring shaft section 23 and the exhaust valve end face 1B, so that the dial indicator 5 can display the measured value according to the displacement of the probe 51. , and compare the measured value with the calibration settin...

Embodiment 2

[0053] A method for detecting a turbocharger volute, using the inspection tool of the first embodiment, including the assembly of the bushing reference shaft 2: inserting the centering shaft section of the bushing reference shaft 2 into the bushing hole 1A of the volute 1, and inserting the The measuring shaft section 23 of the bushing reference shaft 2 extends to the side of the exhaust valve end face 1B, so that the center line of the measuring shaft section 23 coincides with the center line of the bushing hole 1A; The lower end surface is in contact with the low-level surface 61 of the calibration member 6, and the meter seat 3 is pressed down until the lower end surface of the shaft stop 31 is in contact with the high-level surface 62. At the same time, the upper end of the measuring rod 4 drives the measuring head 51 to move and drive the dial indicator. 5 work, set the position of the dial indicator 5 to the zero position at this time; specifically, first match the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com