Steel strength detection device for building detection

A technology for strength detection and steel, applied in the field of steel strength detection devices for building inspection, can solve the problems of high labor cost, low practicability, lower detection efficiency, etc., and achieves high work efficiency, convenient operation and high practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

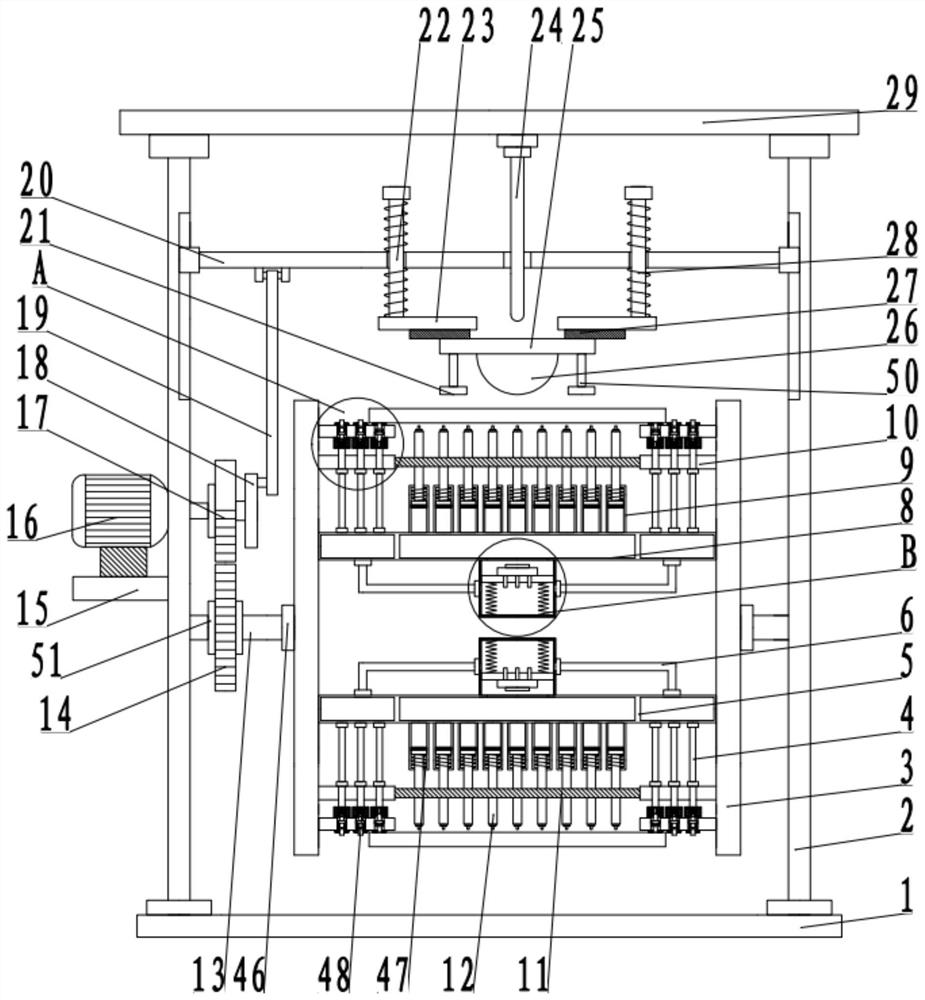

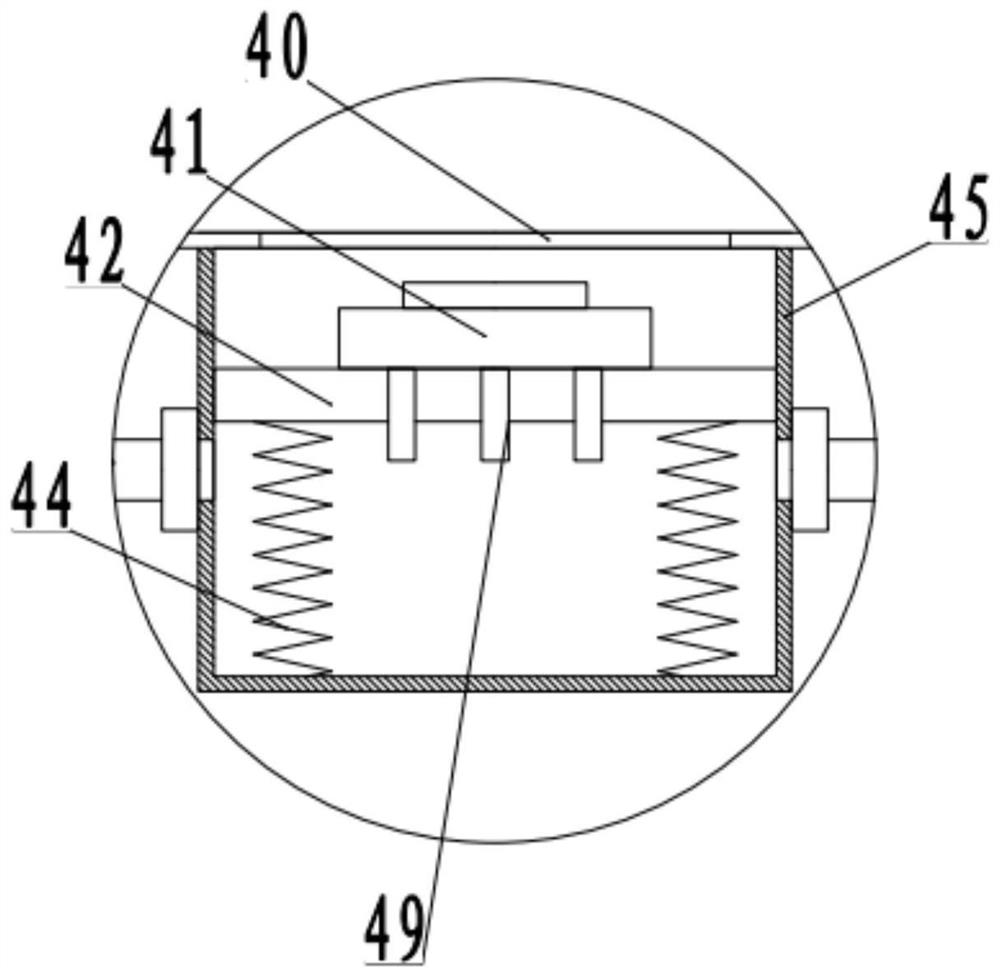

[0026] see Figure 1-5 , a steel strength detection device for building inspection, comprising a bottom plate 1, and also includes: a surrounding plate 2 fixedly arranged on both sides of the bottom plate 1, the top of the surrounding plate 2 is fixedly connected to the top plate 29; a feeding mechanism 46 arranged between the surrounding plates 2 , including the installation column 13, the installation column 13 is rotatably connected with the enclosure plate 2, one side of the installation column 13 is fixedly connected to the installation plate 3, the pressure divider 8 is fixedly connected between the installation plates 3, and both sides of the pressure divider 8 are fixedly connected. The baffle 5, the side wall of the mounting plate 3 is fixedly connected to the fixing rod 10, the fixed rod 10 is fixedly provided with an air guide 4, and the air guide 4 is fixedly connected with the partial pressure cylinder 8, and the installation plate 3 on one side of the air guide 4 ...

Embodiment 2

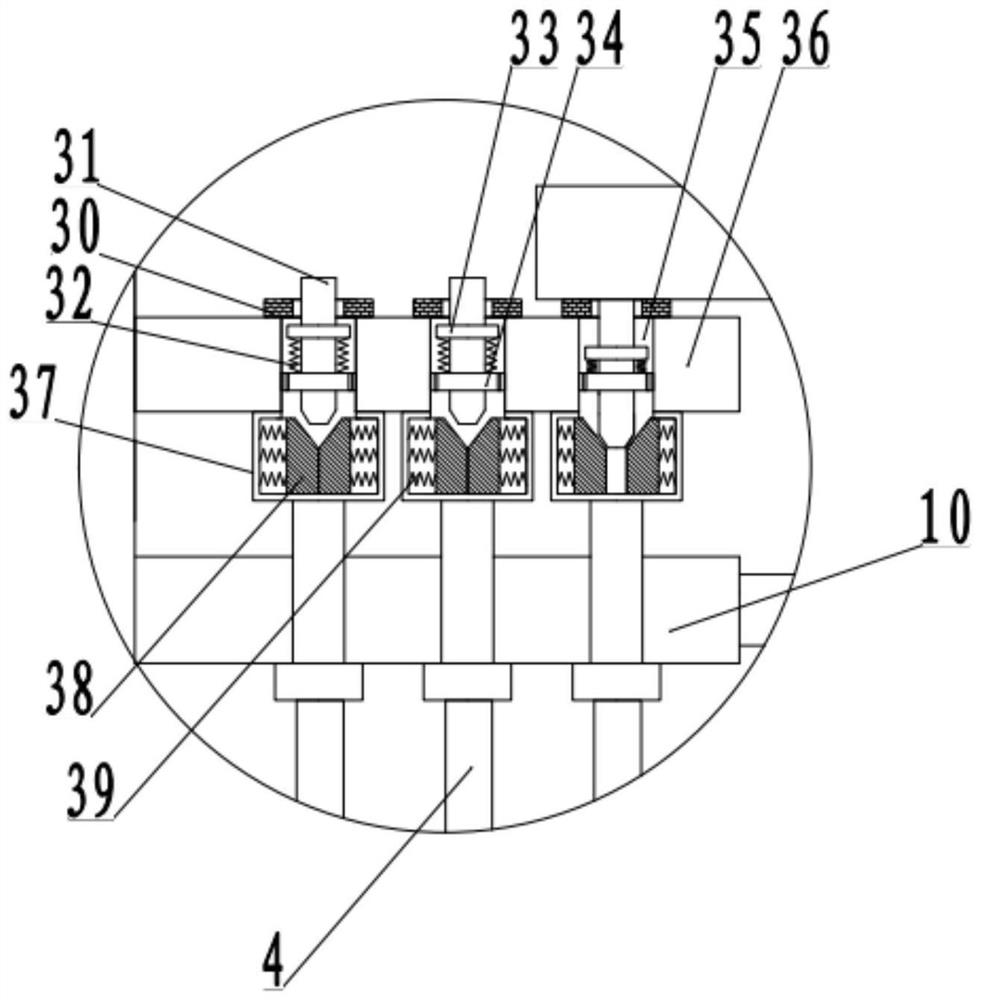

[0029] see Figure 1-5 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the valve assembly 48 includes a mounting arm 36, the mounting arm 36 is fixedly connected with the mounting plate 3, the mounting arm 36 is provided with a through slot 35, and the through slot 35 A venting block 34 is fixedly arranged inside, the venting block 34 is fixedly arranged in the through groove 35, the venting block 34 slides through and sets a valve column 31, the valve column 31 is fixedly sleeved with the installation sleeve 33, the installation sleeve 33 and the ventilation block 34. The reset member 32 is fixedly connected between.

[0030]The mounting arm 36 above the through slot 35 is fixedly connected to the sealing ring 30 , the bottom of the mounting arm 36 below the through slot 35 is fixedly connected to the mounting shell 37 , the inner side wall of the mounting shell 37 is fixedly connected to the telescopic piece 39 , and one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com