Quick dimension labeling method based on three-dimensional factory design drawing

A factory design and dimensioning technology, applied in computer-aided design, calculation, image data processing, etc., can solve problems such as failing to meet drawing requirements, save drawing time, improve dimensioning accuracy and recognizability , the effect of improving the labeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

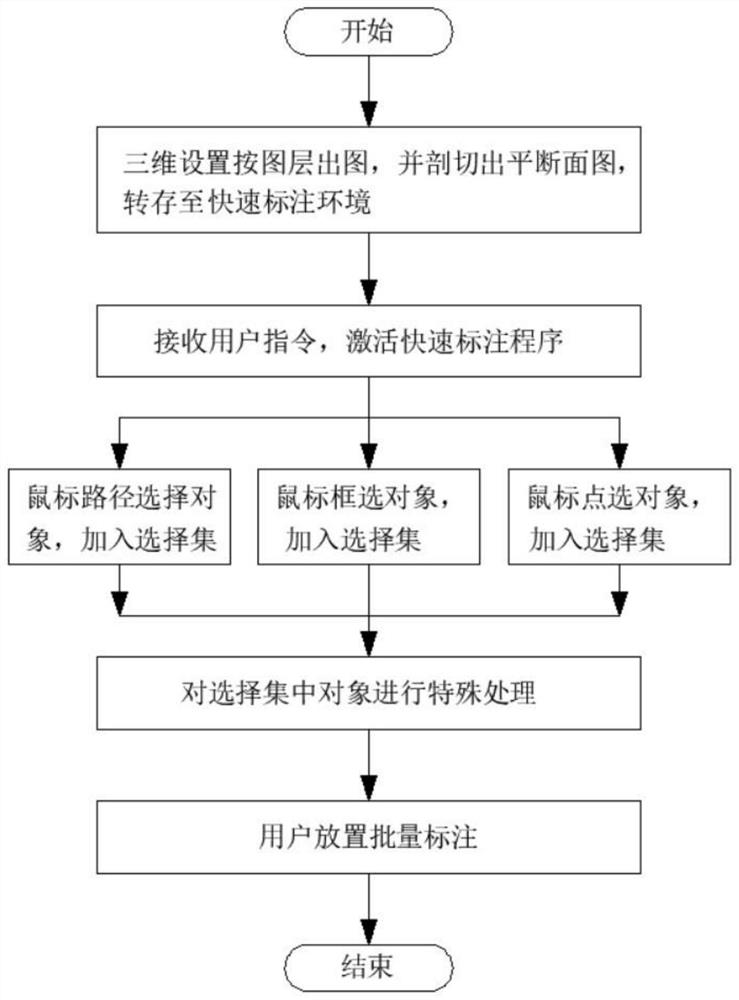

Method used

Image

Examples

Embodiment 1

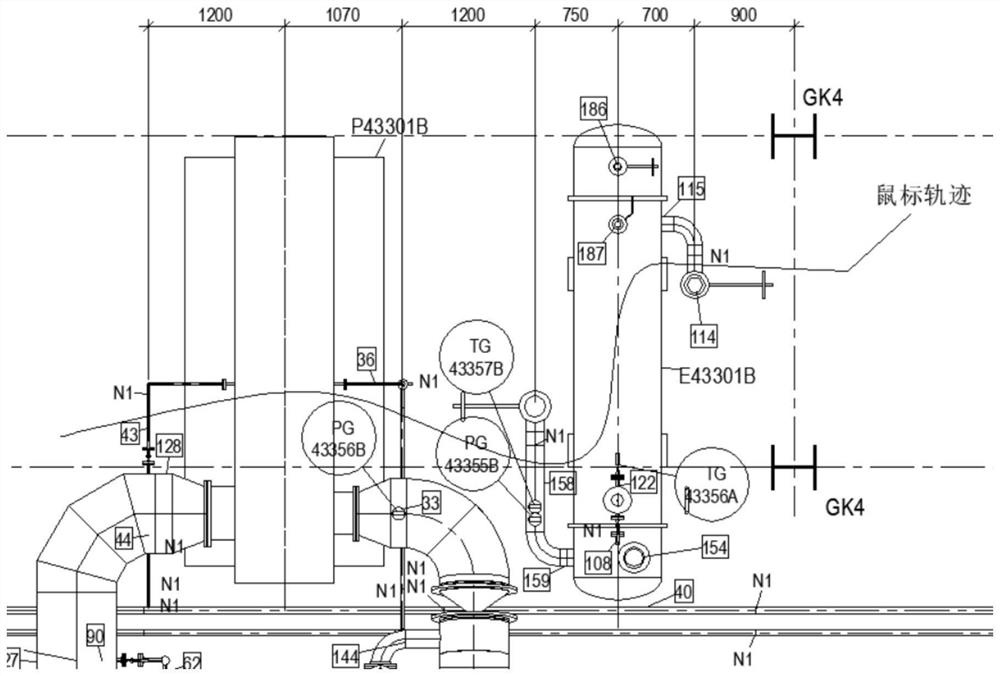

[0099] like figure 2 As shown, in this embodiment, the local map is quickly dimensioned by the mouse track, and the specific batch dimensioning steps are:

[0100] 1. After the user activates the program, record the mouse active path, pick up the axisymmetric center lines of the equipment, pipelines, and building structures that intersect the path, draw the virtual center line Center, and add it to the annotation set together with the picked Center layer line;

[0101] 2. Process the objects in the annotation set, and obtain the endpoint coordinates and midpoint coordinates of the Center line of each annotation object;

[0102] 3. The user interactively executes the labeling to the top of the view, obtains the upper end point of the vertical Center as the labeling point, and performs batch labeling on all vertical Center lines in the labeling set; batch labeling is performed in the same way when labeling is drawn to other directions of the view;

[0103] 4. If the labeling p...

Embodiment 2

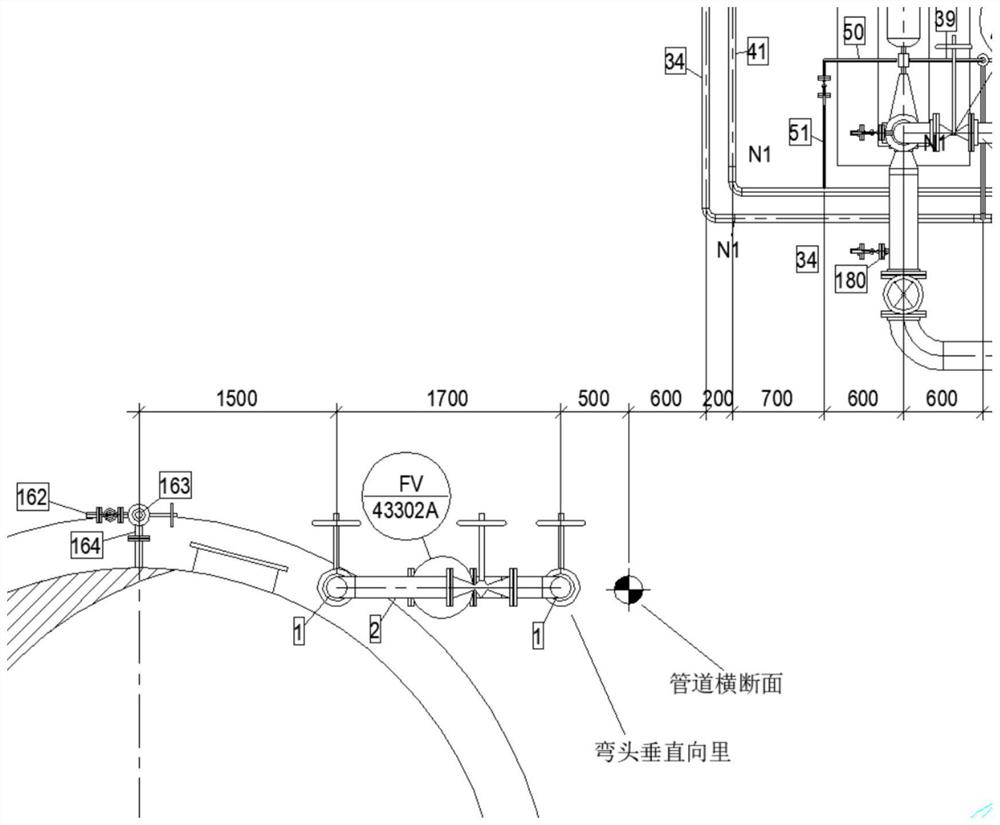

[0106] like image 3 As shown, in this embodiment, the local diagram is quickly dimensioned by frame selection or click selection, and the specific batch dimensioning steps are:

[0107] 1. Use the mouse to select (positive or negative selection) or click objects, and select the characteristic objects such as pipes, equipment, building structures, pipe elbows, center lines (line type is CENTER), circles, arcs, and pipe cross-sections. join selection set;

[0108] 2. For feature objects such as pipe elbows, pipe cross-sections, circles, and arcs, the center of the circle is taken as the marking point, and the end point or midpoint of the line is taken as the marking point;

[0109] 3. The user interactively executes the labeling to the middle of the view, and batch labels all vertical Center lines and feature objects in the labeling set according to the labeling points;

[0110] 4. In the present embodiment, the labeling position is located in the view, and the end point and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com