Composite circuit board and manufacturing method thereof

A manufacturing method and circuit board technology, which are applied in the directions of printed circuit components, secondary processing of printed circuits, reinforcement of conductive patterns, etc., can solve problems such as sacrificial circuit layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

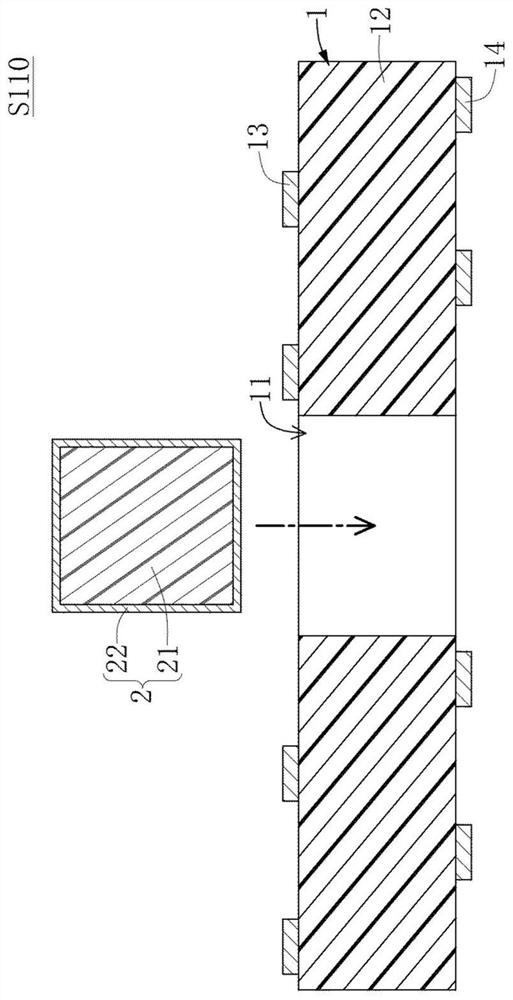

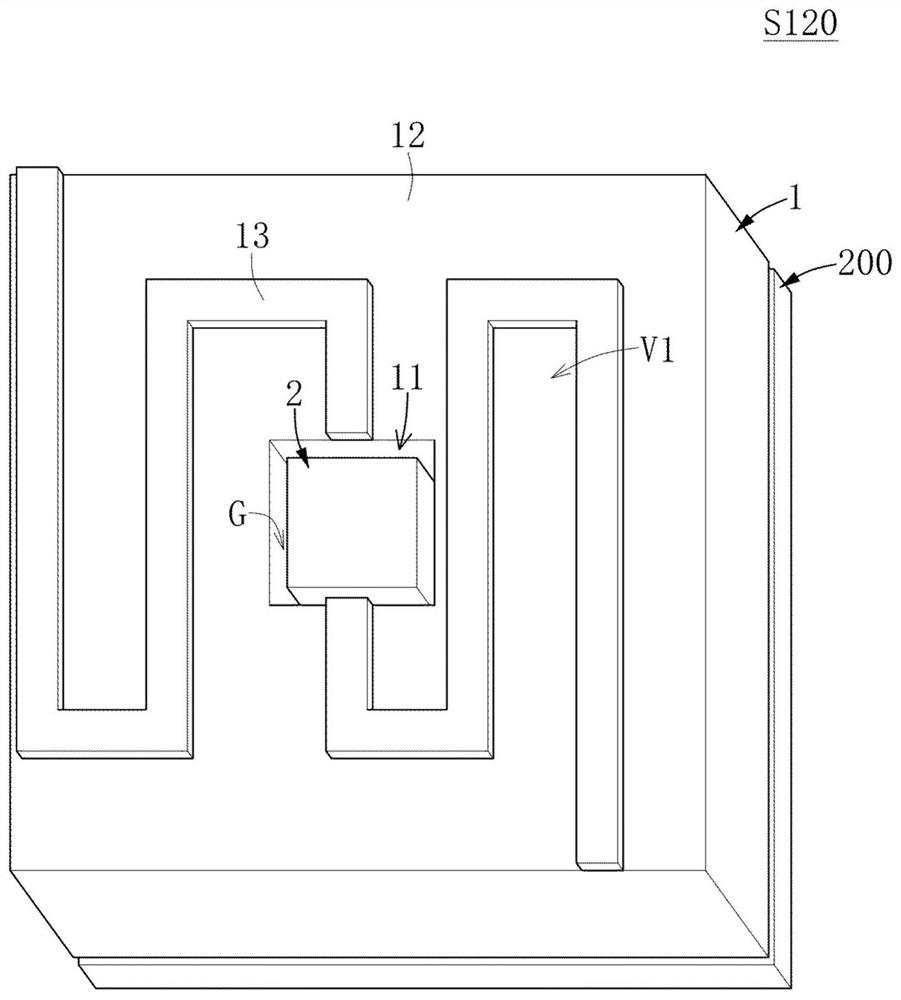

[0051] see Figure 1 to Figure 9 As shown, it is the first embodiment of the present invention. This embodiment discloses a composite circuit board 100 and a method for manufacturing the same. To facilitate the description of this embodiment, the following first describes the method for manufacturing the composite circuit board, and then describes the composite circuit board 100 . Wherein, the composite circuit board 100 is manufactured by implementing the manufacturing method of the composite circuit board in this embodiment, but the present invention is not limited thereto.

[0052] see Figure 1 to Figure 9 As shown, it is a schematic flowchart of the manufacturing method of the composite circuit board. Wherein, the manufacturing method of the composite circuit board in this embodiment sequentially includes a preparation step S110, an insertion step S120, a printing step S130, a thickening step S140, a planarization step S150, and an electroplating step. S160, and a patt...

Embodiment 2

[0076] see Figure 10 and Figure 11 As shown, it is the second embodiment of the present invention. Since this embodiment is similar to the above-mentioned first embodiment, the similarities between the two embodiments will not be repeated, and the differences between this embodiment and the first embodiment are roughly described as follows:

[0077] In this embodiment, the ceramic block 2 does not include the conductive layer 22 in the first embodiment; that is, the ceramic block 2 in this embodiment is equivalent to the ceramic body 21 in the first embodiment. Accordingly, the first circuit extension area 221 is defined on the surface of the ceramic block 2 adjacent to the first circuit layer 13 and exposed outside the insulating ink 3 (eg: Figure 11 The top surface of the ceramic block 2 in the middle), and the second circuit addition area 222 is defined on the surface of the ceramic block 2 adjacent to the second circuit layer 14 and exposed outside the insulating ink ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com