Automatic stitching of footwear components

A technology for footwear and components, applied in footwear, shoe-making machinery, shoe uppers, etc., can solve problems such as increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

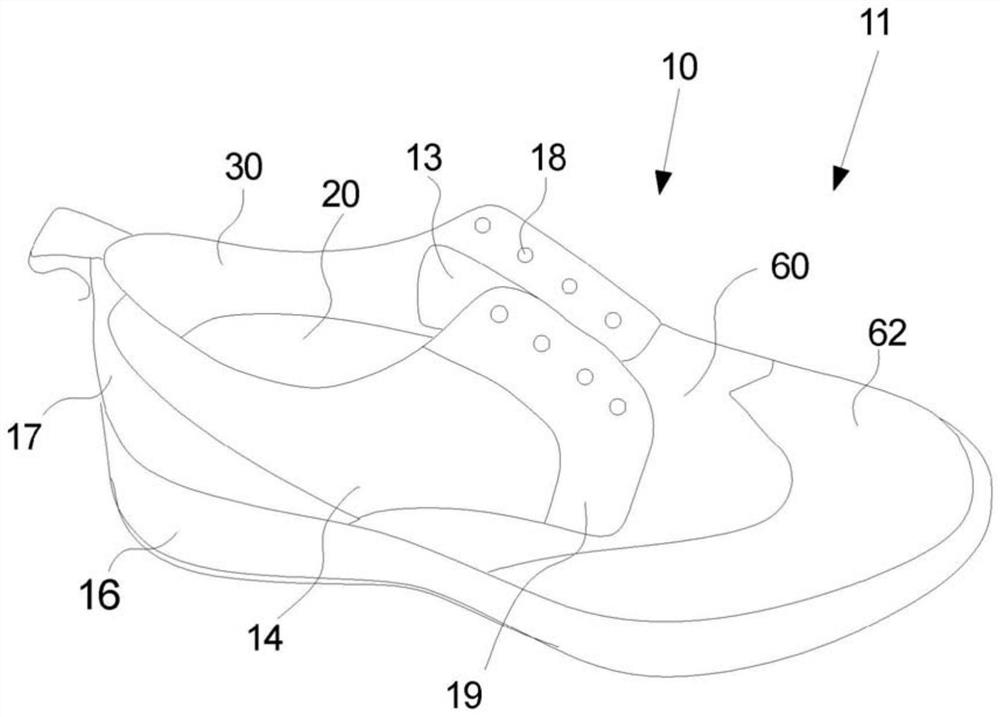

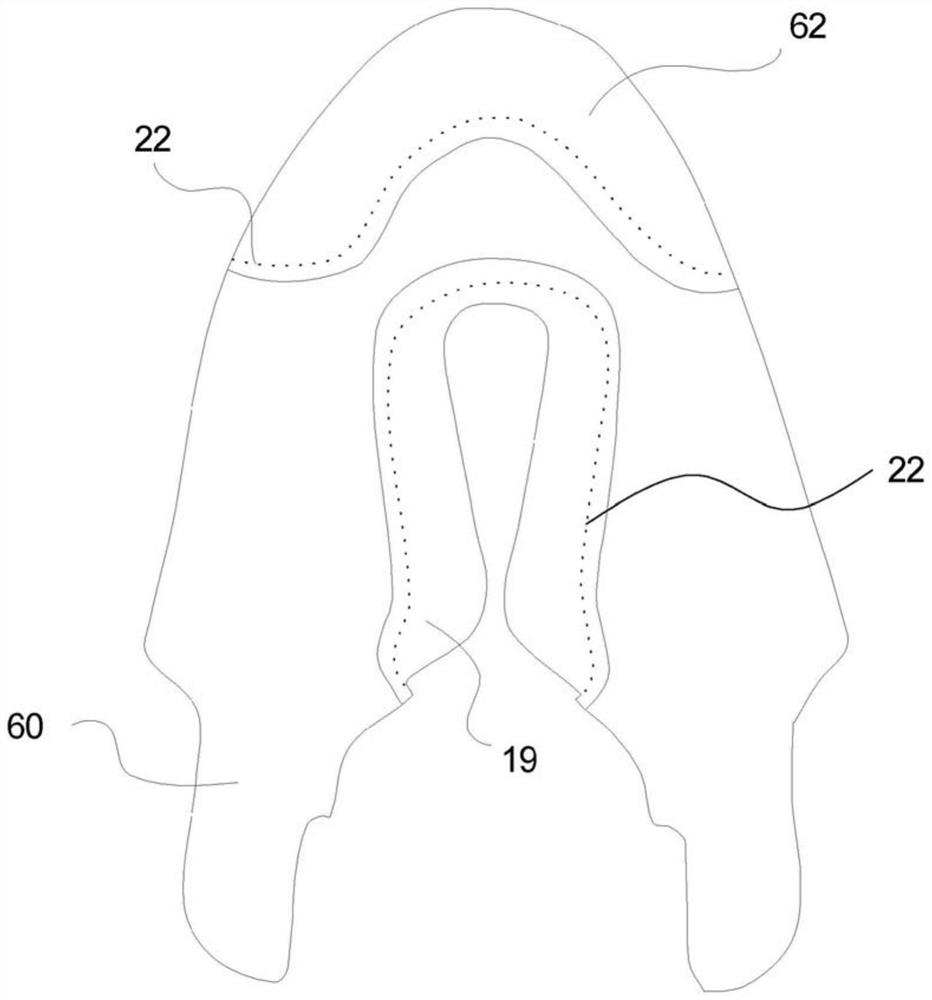

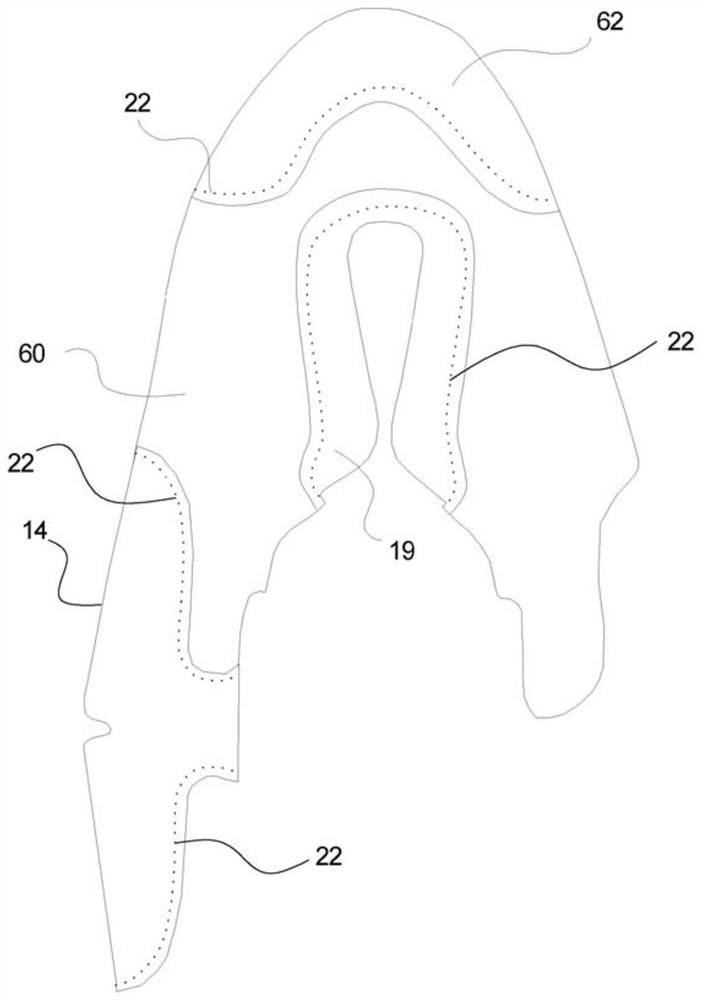

[0164] figure 1Exemplary footwear that can be manufactured within the scope of the present invention is shown. An exemplary footwear is shoe 10 that includes upper 11, wherein upper 11 includes a plurality of footwear-defining components. The footwear-defining component is exemplified by the front upper 60, the portion of the upper that covers the front of the foot up to the junction of the waist; the tongue 13 is defined as the strip of material located under the laces. The tongue may be located on the top central portion of the shoe at the top of the arch and may be attached to the forefoot 60; the waist 14 is located at the back and sides of the heel-covering upper behind the forefoot. The heel portion 14 of the waistband may be reinforced with reinforcements that help support the back of the foot. In addition, the toe cap 62, where the toe cap can take various forms but the type can be a complete replacement for the front upper of the shoe; sewn to the toe cap, adding an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com