Method and apparatus for producing tyres for vehicle wheels

A technology of tires and wheels, applied in tires, applications, household appliances, etc., can solve the problem of increased waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

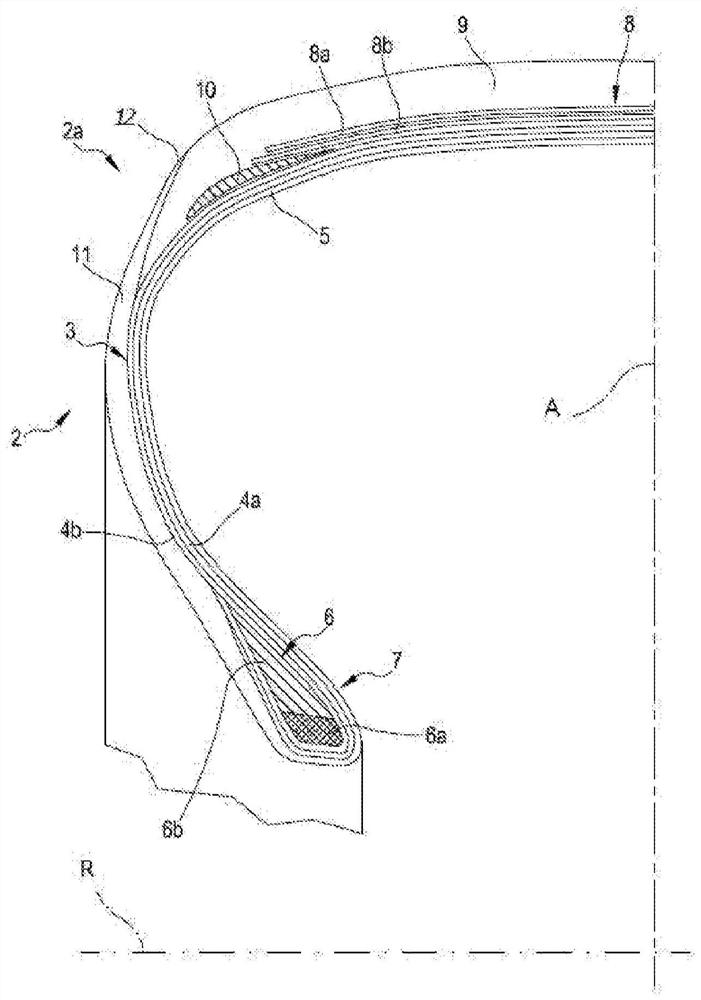

[0178] exist figure 1 , an example of a tire that can be produced in the apparatus 1 for producing tires for vehicle wheels according to the present invention is denoted by reference numeral 2 .

[0179] The tire 2 has a median plane A perpendicular to its axis of rotation R (at figure 2 , the position of the axis of rotation R relative to the section of the tire 2 is shown in an indicative and schematic manner). The median plane A divides the tire 2 into a first axial half 2a and a second axial half. To simplify the description, figure 2 Only the first axial half 2a of the tire 2 is shown, the other half is substantially a mirror image of the first axial half 2a (except for the possibly asymmetrical tread pattern with respect to the above-mentioned median plane A).

[0180] The tire 2 basically comprises a carcass structure 3 with one or two carcass plies 4a, 4b. In a radially inner position relative to the one or both carcass plies 4a, 4b an impermeable layer of elasto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com