Gas generator

A technology for gas generators and shells, which is applied to weapon accessories, vehicle components, pedestrian/passenger safety arrangements, etc. It can solve the problems of low volume compensation, low stability, expensive silicone molded body, etc., and achieve the goal of increasing pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

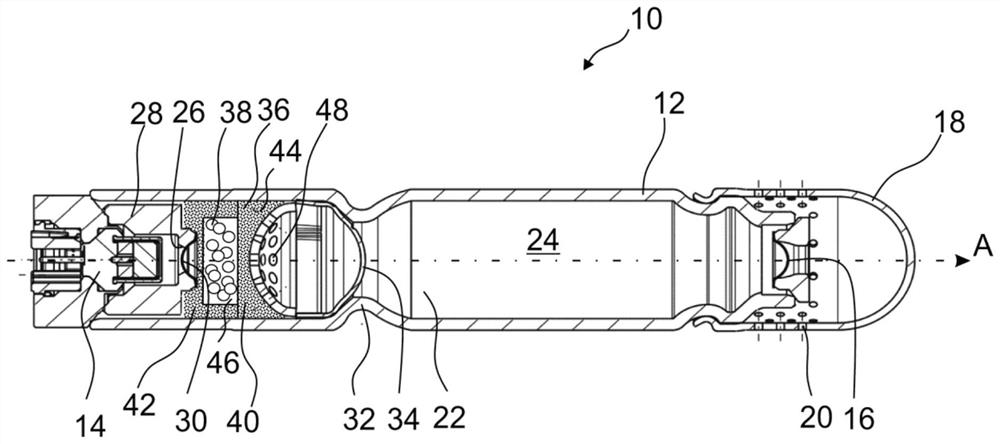

[0038] figure 1 A gas generator 10 according to the present invention is shown. The gas generator 10 has an elongated cylindrical housing 12 at a first axial end of which an igniter 14 is provided and at a second axial end of which the housing 12 The membrane 16 is closed from the environment of the gas generator 10 .

[0039] A diffuser 18 provided with outflow openings 20 is connected in the axial direction to the housing 12 and directs the gas flowing out of the diffuser 18 to the safety device (not shown) to be activated.

[0040] The housing 12 defines a pressure chamber 22 which is connected in the axial direction A to the igniter 14 . The pressure chamber 22 is filled with compressed pressurized gas 24 .

[0041] The pressurized gas 24 includes at least one inert gas, such as argon, helium, and / or nitrogen or another suitable gas mixture, and may also include a gaseous oxidant. In this case, the gaseous oxidant consists in particular of a major part, ie more than 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com