Water purification microfiltration equipment

A technology of microfiltration and equipment, applied in the direction of filtration separation, fixed filter element filter, separation method, etc., can solve the problems of low filtration efficiency, affecting the effect and efficiency of filtration, unfavorable long-term use of sewage filtration, etc., to achieve improved purification Efficiency, improve the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

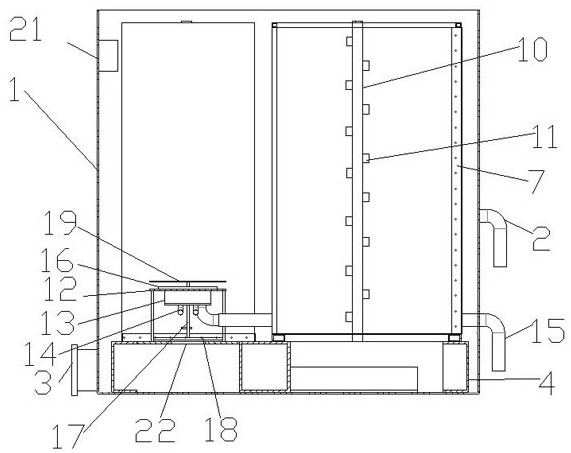

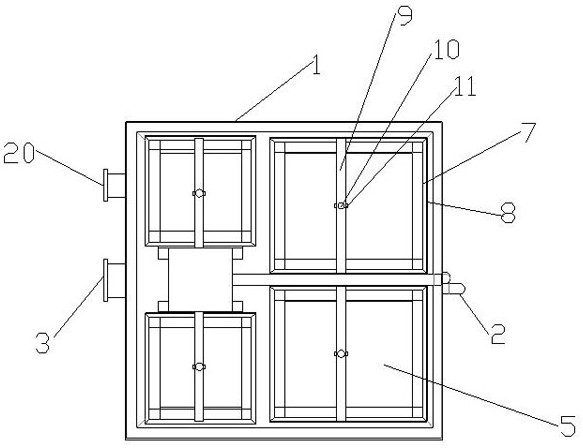

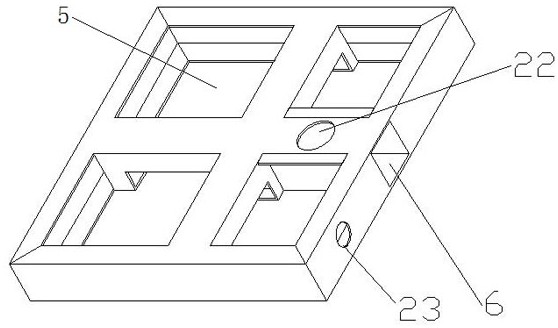

[0024] like Figure 1-3 As shown, the present invention is a water purification microfiltration device, comprising a water storage tank 1, the side of the water storage tank 1 is respectively provided with a first water outlet 3 and a first water inlet 2, and the water storage tank 1 is provided with four groups of rectangular The filter screen unit uses the filter screen unit to accurately and efficiently filter the impurities contained in the sewage. The bottom of the water storage tank is fixedly connected with a bottom plate 4, the bottom plate 4 is a hollow structure, and the upper part of the bottom plate 4 is provided with four A group of rectangular through holes 5, the position and number of the through holes 5 correspond to the screen unit, the side of the bottom plate 4 is provided with a bottom plate water outlet 6, and the bottom plate water outlet 6 communicates with the first water outlet 3 . During operation, the sewage enters the water storage tank 1 through ...

Embodiment 2

[0034] The difference between Embodiment 2 and Embodiment 1 lies in the water discharge mechanism sealed on the upper part of the water discharge port 22, the water discharge mechanism is an electromagnetic valve, the water discharge port is fixedly connected to an electromagnetic valve, and the electromagnetic valve is connected to a controller.

[0035] When working, after the sewage in the water tank reaches the warning line, the liquid level sensor 21 sends an electrical signal to the controller, the warning device sends out an alarm, the staff closes the first water outlet 3, and simultaneously opens the second water outlet 20, which is opened through the control panel. Solenoid valve, the water in the water tank is discharged through the second water outlet 20, the second high-pressure water pump is activated through the control panel, the high-pressure water of the second high-pressure water pump enters the water spray pipe 10, and the high-pressure water is sprayed from ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap