Hot-pressing device for quickly forming multilayer building template

A technology of construction formwork and hot pressing device, which is applied in the direction of lamination device, lamination, lamination auxiliary operation, etc. It can solve the problems of inconvenient formwork pick and place, inability to limit formwork, formwork displacement, etc., to achieve convenient operation, Avoid the effect of template displacement and avoid impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

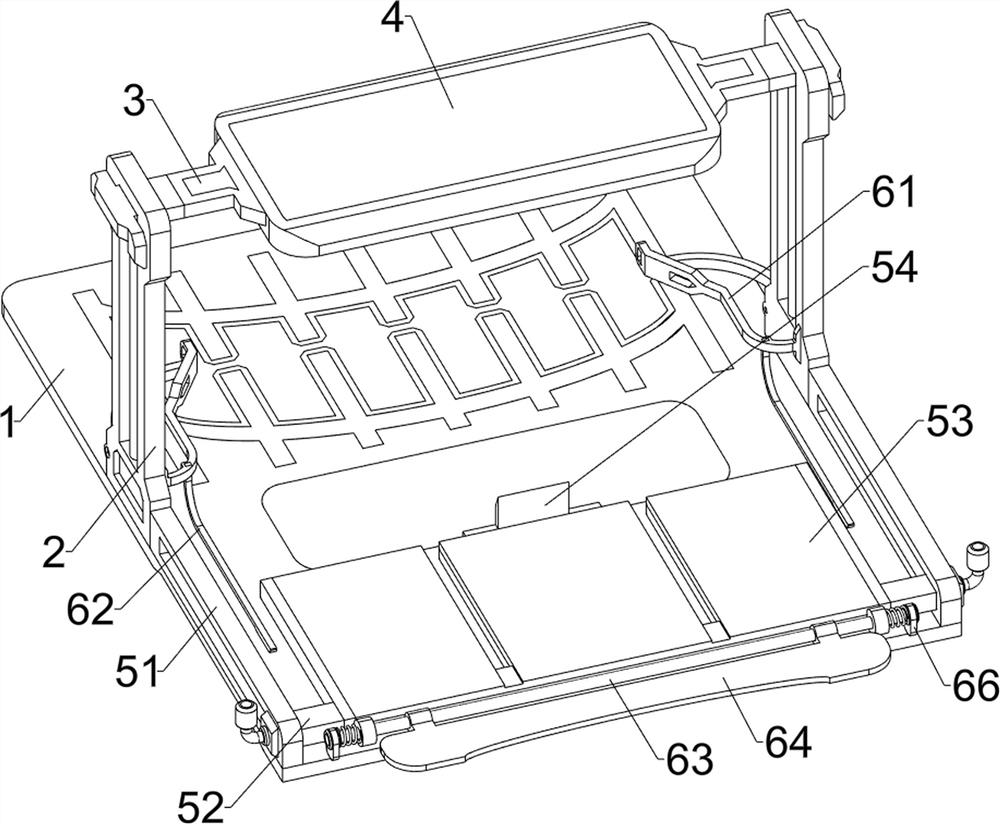

[0031] A rapid prototyping multi-layer building formwork hot pressing device, such as Figure 1-3 As shown, it includes a fixed plate 1, an electric slide rail 2, a connection block 3, a hot pressing plate 4, a transport mechanism 5 and a limit mechanism 6. The upper side of the middle of the fixed plate 1 is symmetrically installed with an electric sliding plate connected by screws. Rail 2, the upper part of the electric sliding rail 2 is slidably provided with a connecting block 3, a hot pressing plate 4 is welded between the two connecting blocks 3, and a transport mechanism 5 is arranged on the fixed plate 1, and the transport mechanism 5 and the electric sliding rail 2 are arranged between A limiting mechanism 6 is provided.

[0032] like figure 2 As shown, the transport mechanism 5 includes a guide rail 51, a sliding block 52, a placing board 53 and a clamping board 54, and a guide rail 51 is bolted symmetrically on the upper side of the front part of the fixed plate 1...

Embodiment 2

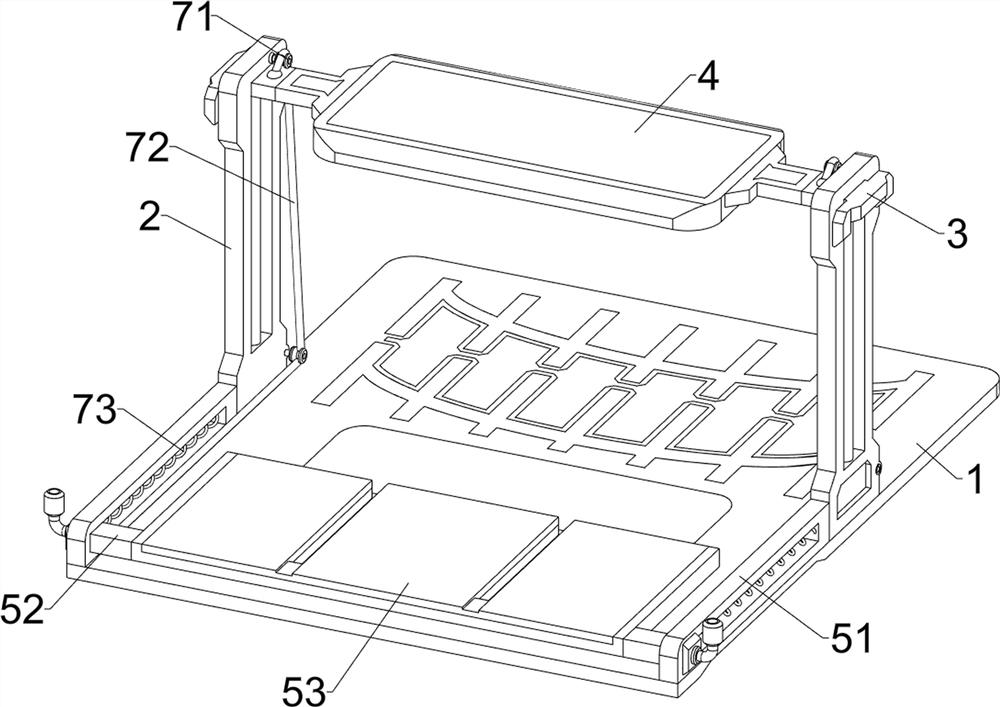

[0036] On the basis of Example 1, as figure 1 , Figure 4 and Figure 5 As shown, it also includes a power mechanism 7. The power mechanism 7 includes a pulley 71, a pulling rope 72 and a first spring 73. Two pulleys 71 are rotatably provided on the opposite sides of the two electric sliding rails 2. The pulley 71 is arranged up and down, a pull rope 72 is connected between the slider 52 and the hot pressing plate 4 on the same side, the pull rope 72 goes around the pulley 71, and a first spring 73 is connected between the slider 52 and the guide rail 51 on the same side .

[0037] When the operator places the template on the placing plate 53, the operator starts the electric slide rail 2, so that the electric slide rail 2 drives the hot pressing plate 4 to move downward through the connecting block 3, and the connecting block 3 moves downward through the pulling rope 72. Pull the slider 52 to move backward, the first spring 73 compresses, the slider 52 will drive the templ...

Embodiment 3

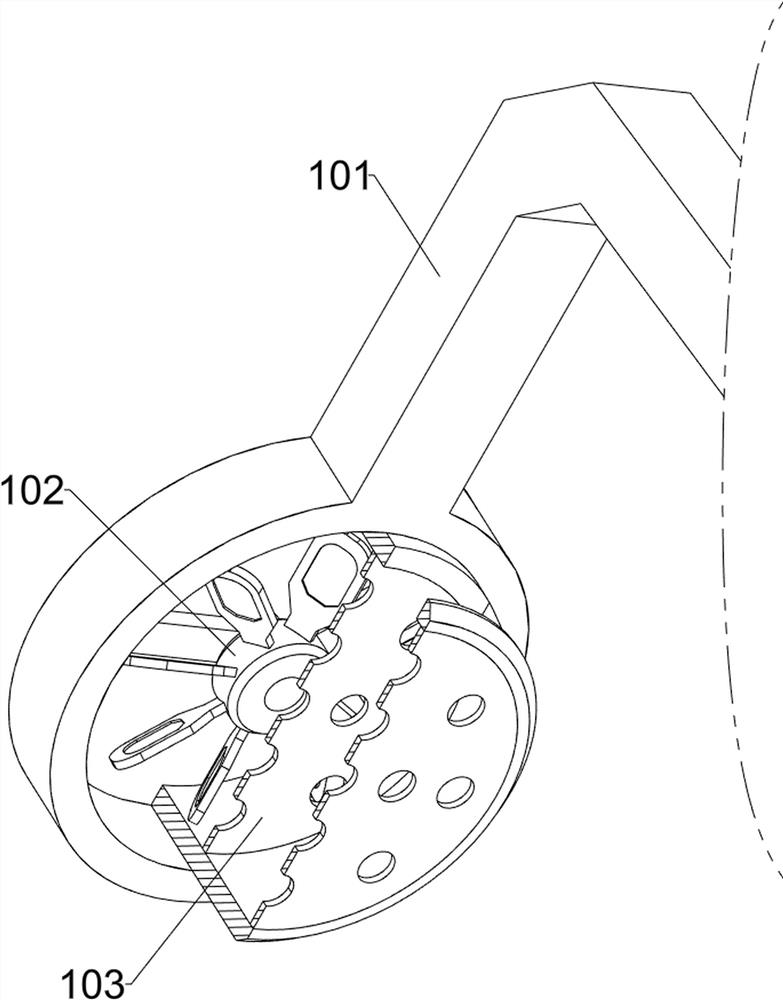

[0039] On the basis of Example 2, as figure 1 and Image 6 As shown, it also includes a scraping mechanism 8, the scraping mechanism 8 includes a first connecting rod 81, a second spring 82 and a scraper 83, a first connecting rod 81 is bolted on the upper side of the guide rail 51, and two first connecting rods A scraper 83 is slidably sleeved between the upper part of the rod 81 . The upper side of the scraper 83 is symmetrically provided with a rubber handrail, which can facilitate the movement of the scraper 83 . A second spring 82 is connected between the scraper 83 and the first connecting rod 81 .

[0040] When placing the multi-layer template to be hot-pressed on the placement plate 53, the operator drives the scraper 83 to move downward, the second spring 82 is compressed, and the scraper 83 moves downward to scrape off the adhesive overflowing from the outside of the template, and then the operator When the scraper 83 is released, the second spring 82 is reset, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com