Butterfly valve with silt particle prevention mechanism

An anti-sediment and particle technology, applied in the direction of lifting valves, valve devices, mechanical equipment, etc., can solve the problems of butterfly valve opening and closing resistance, inability to complete opening and closing control, and blockage of butterfly valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

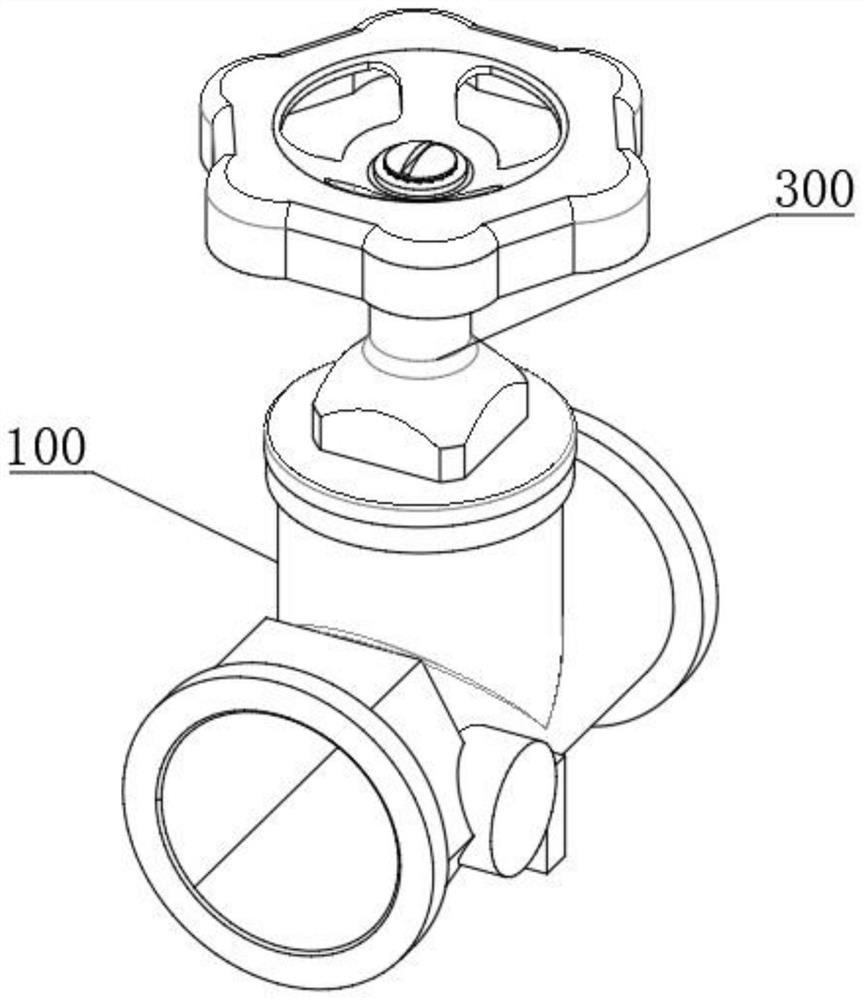

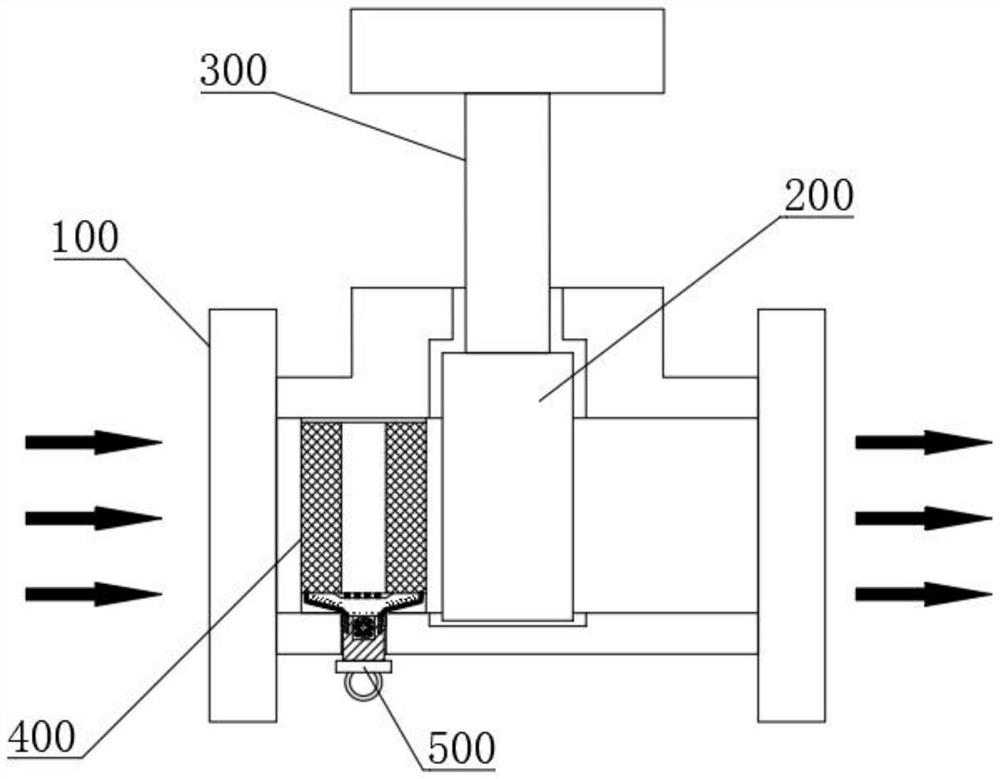

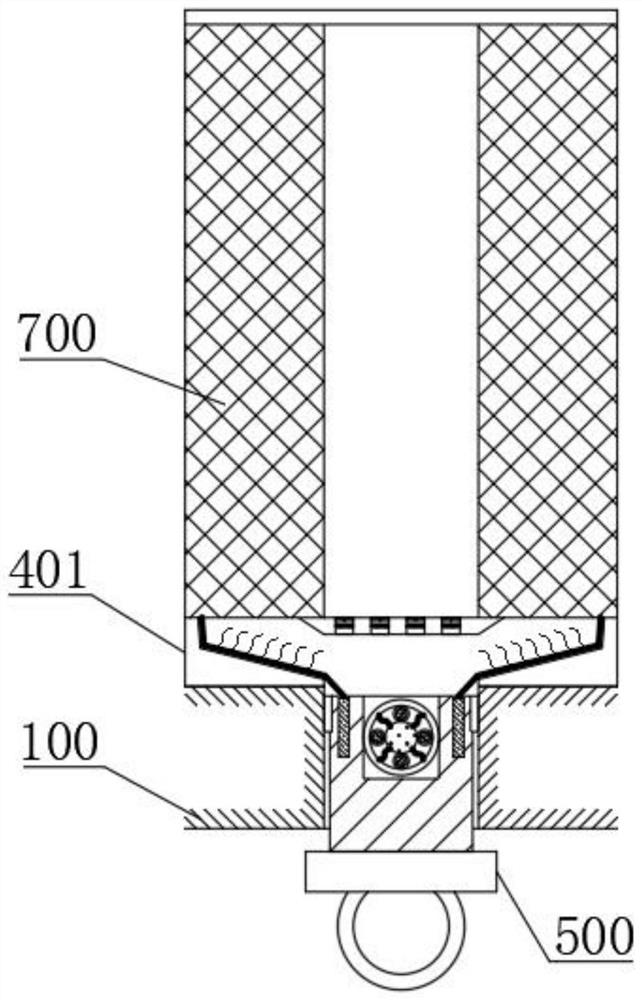

[0043] see Figure 1-3 , a butterfly valve with an anti-sand particle mechanism, comprising a valve seat 100, a valve plate 200 is rotatably connected in the valve seat 100, a valve stem 300 is rotatably connected to the upper end of the valve seat 100, the valve stem 300 is connected with the valve plate 200, and the valve The seat 100 is provided with an anti-clogging mechanism 400, the lower end of the valve seat 100 is drilled with a conducting port, and the conducting port is provided with a multi-functional blocking mechanism 500. In this solution, when the valve plate 200 is opened to allow water flow in the valve seat 100, the water flow Entering from the left side of the anti-clogging mechanism 400, when passing through the sediment interception net 700, the sediment particles in the water flow will be intercepted by the sediment interception net 700, and the water flow will directly pass through the sediment interception net 700, and be intercepted by the sediment int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com