Hub gravity casting four-opening pressurizing die

A technology of gravity casting and pressurized molds, which is used in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of loose distribution of aluminum liquid and insufficient internal structure of castings, and achieves easy mold opening and mold opening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

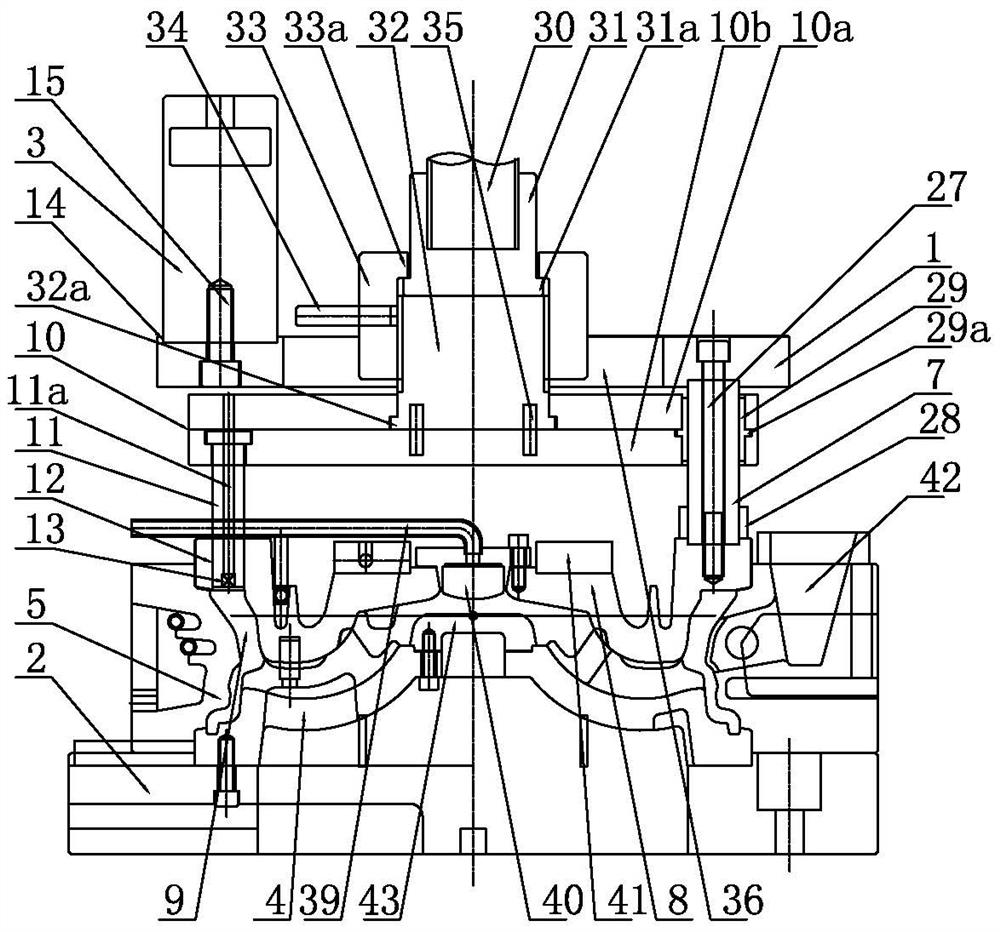

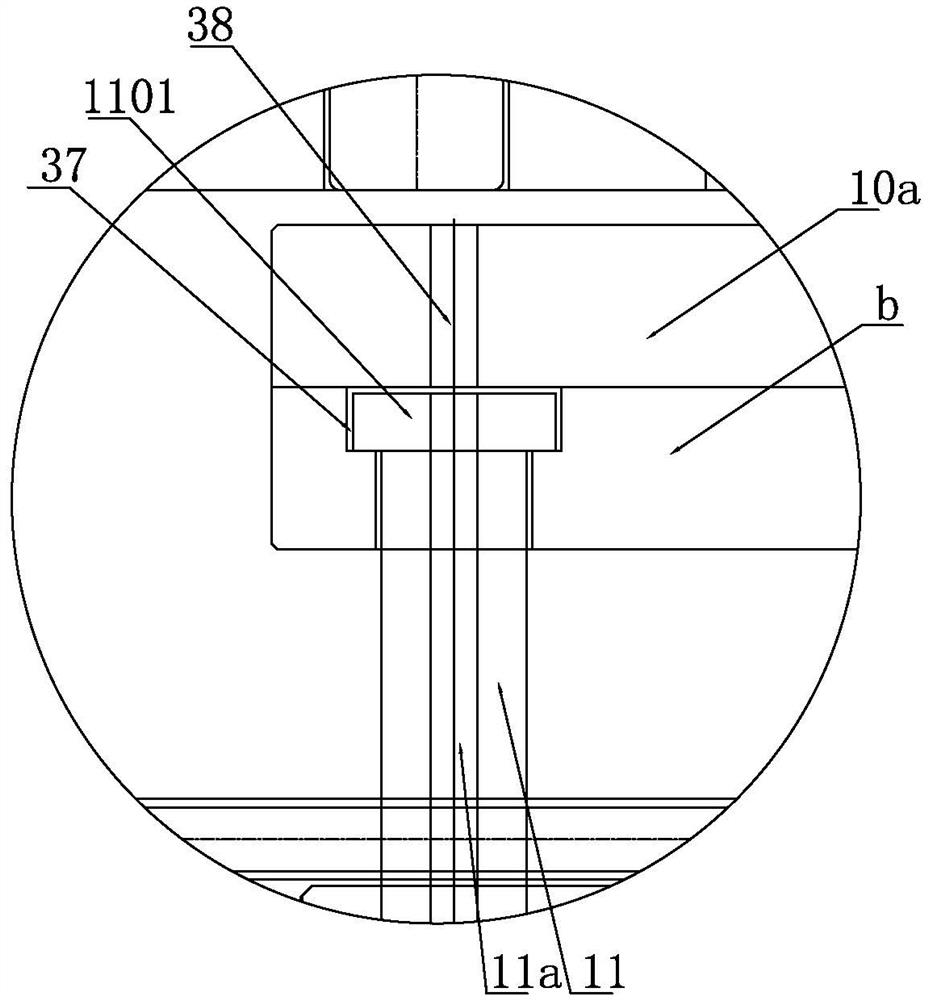

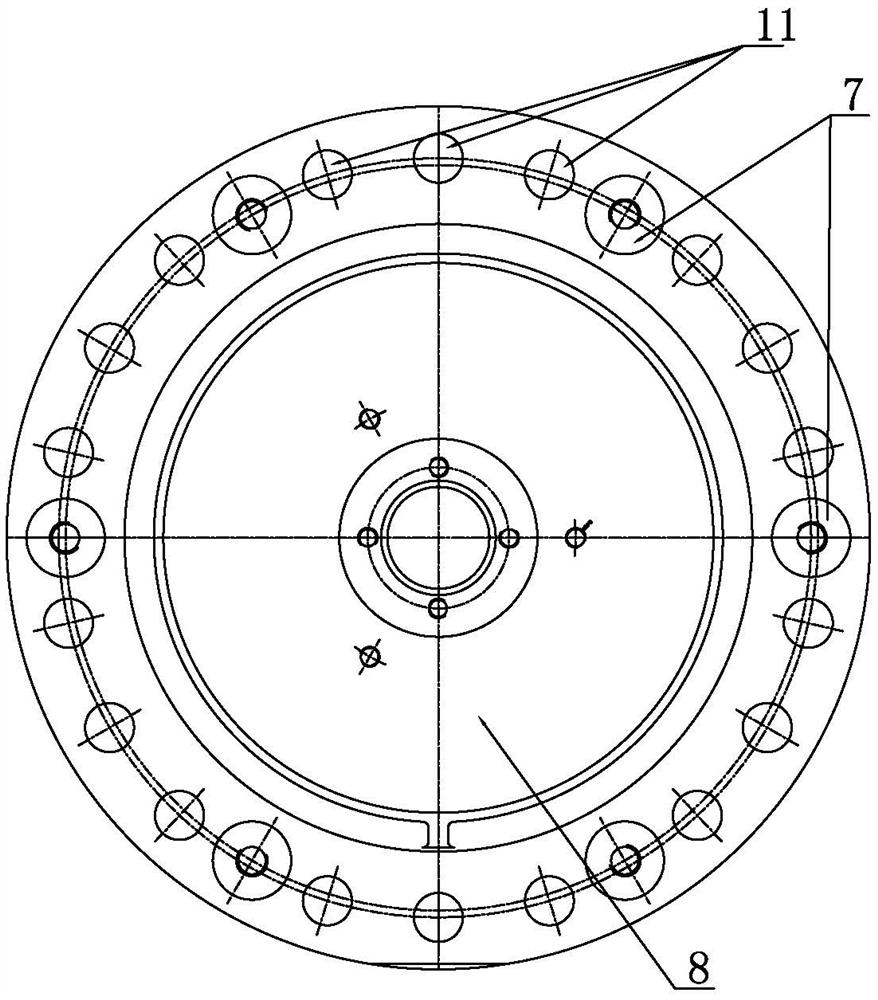

[0028] like Figure 1-13 As shown, it is a wheel hub gravity casting four-open pressurized mold, including a horizontally arranged upper template 1 and a lower template 2, and a number of mounting columns 3 are vertically arranged on the upper side of the upper template 1, and the upper ends of each mounting column 3 are Correspondingly, it is connected with the horizontal cylinder plate, and the cylinder plate is connected with the extension end of the piston rod of the lifting cylinder. The lower template 2 is arranged on the base. The lower template 2 is provided with a lower mold 4. The mold 4 is correspondingly provided with four side molds 5, and the four side molds 5 are symmetrically distributed in pairs. The lower template 2 is provided with at least two inclined side opening guide rails 6 corresponding to each side mold 5, which are connected with each side mold 5. Correspondingly, a side-opening drive mechanism is provided. The lower side of the upper template 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com